Solid support method for biological material and produced multifunctional nano-cage type bioreactor

A technology of bioreactors and biomaterials, applied in the direction of enzyme production/bioreactors, fixed on/in organic carriers, etc., can solve the problems of difficult control of caliber, solution pollution, narrow material stability range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A highly stable and reusable dual-functional nanocage bioreactor with myoglobin as the active center and lysozyme as the pore size modification material

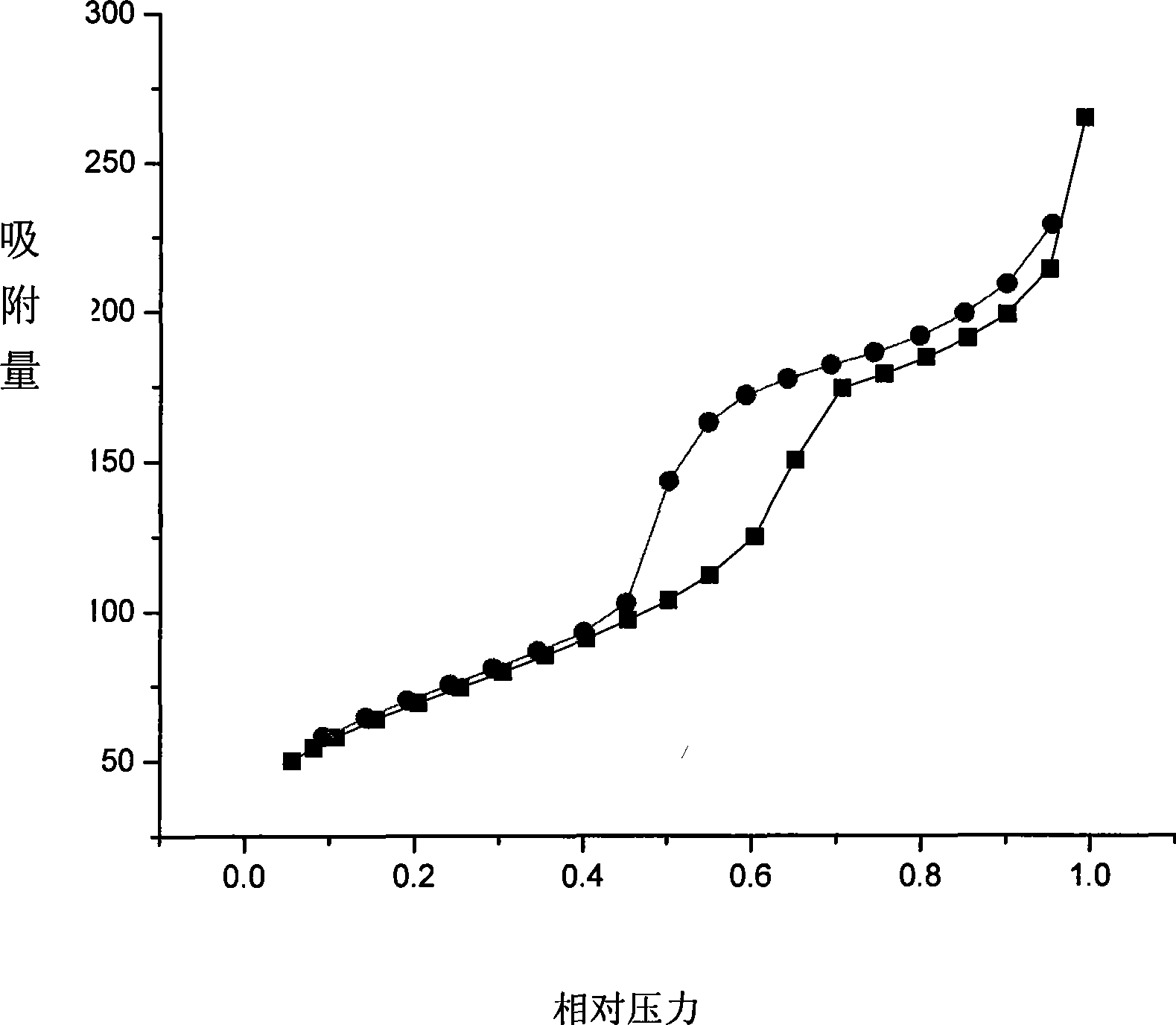

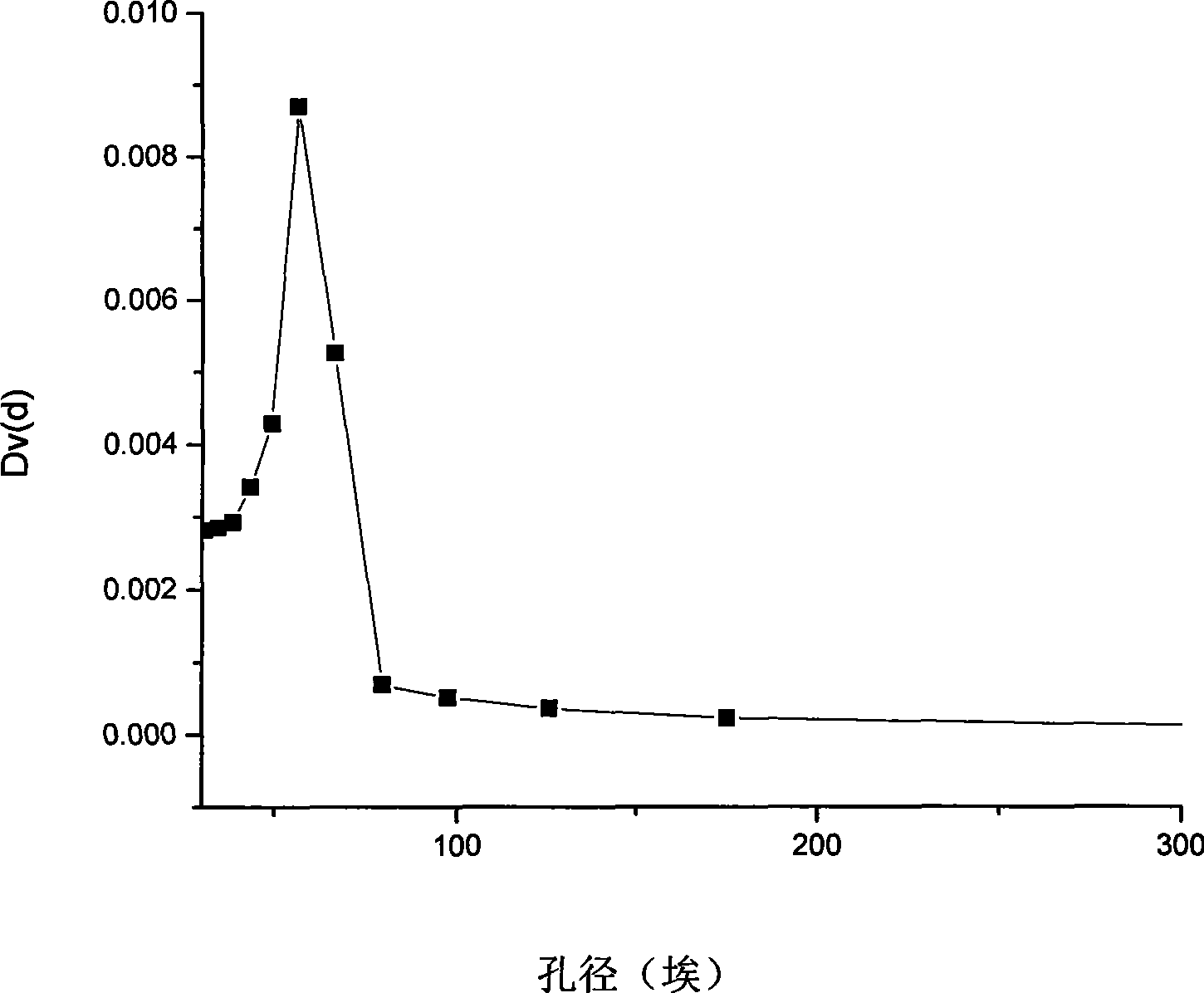

[0017] Using tetraethyl orthosilicate as the silicon source, P123 as the surfactant, APTES as the amination reagent, and glutaraldehyde as the crosslinking agent to synthesize the mesoporous silicon structure ingredient SiO2 / surfactant / APTES / HCl / H 2 O mass ratio is 1 / (4~5) / (10~14) / (120~300), crude product / ethanol / H 2 O mass ratio is 1.2 / 307 / 16; aminated mesoporous material / myoglobin / glutaraldehyde / H 2 The mass ratio of O / lysozyme is 1 / (0.1-0.5) / (0.01-2) / (10-50) / (0.01-0.2). The molecular sizes of myoglobin and lysozyme are 4.5nm×3.5nm×2.5nm and 4.5nm×3.0nm×3.0nm, respectively, which are smaller than the general pore size of mesoporous materials; because myoglobin has catalase activity, the use of As the active center of catalysis, it is connected with lysozyme to reduce the pore size and prevent myoglobin from esca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com