Flame-retardant PVC wood-plastic profile and preparation method thereof

A technology of wood-plastic profiles and PVC resin, which is applied in the field of flame-retardant PVC materials, can solve the problems of polluting the environment, human body or equipment, loss of life and property, and difficulties in firefighting, and achieves the effects of reducing production costs and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0036] 1. Pretreatment:

[0037] Put the wood flour with a particle size of 60 mesh into the dryer at a temperature range of 200°C, heat it for 15 minutes for baking treatment, dry the water and evaporate the impurities. Add the baked wood flour to a high-speed mixer, stir and heat to 90°C, add a silane coupling agent of 2% of the total weight of the polishing slag, mix the silane coupling agent and absolute ethanol in a ratio of 1:1, and spray it on the polishing slag Surface, stir at high speed for 10 minutes to activate; discharge the material into the cold mixer and stir for 8 minutes, discharge after cooling to obtain surface activated wood powder, and set aside.

[0038] 2. Mixing:

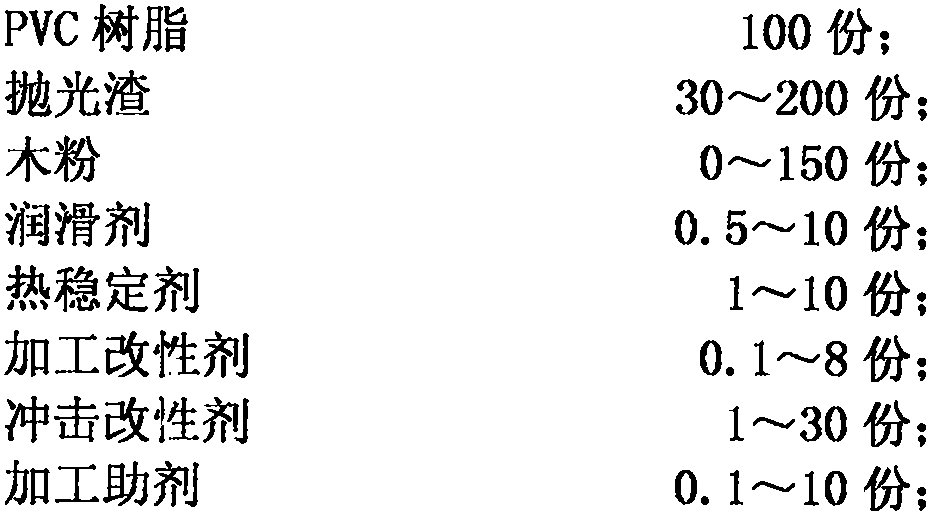

[0039]The various raw material formulas that make up the flame-retardant PVC wood-plastic profile are weighed according to the following mass fractions respectively, and set aside.

[0040]

[0041] Put the PVC resin powder into the high-speed mixer, stir at high speed for 7 minutes to ...

Embodiment approach 2

[0046] 1. Pretreatment:

[0047] Add the wood powder with a particle size of 60 mesh into the dryer at a temperature of 210°C, heat it for 10 minutes for baking treatment, dry the water and evaporate the impurities. The wood flour after baking treatment is added to a high-speed mixer and heated to 100 ° C, and a titanate coupling agent of 1.5% of the total mass of the wood flour is added, and the titanate coupling agent and chlorinated paraffin are mixed in a ratio of 1:1. Spray on the surface of polishing slag, stir at high speed for 8 minutes to activate; discharge the material into the cold mixer and stir for 10 minutes, discharge after cooling to obtain activated wood powder, and set aside.

[0048] 2. Mixing:

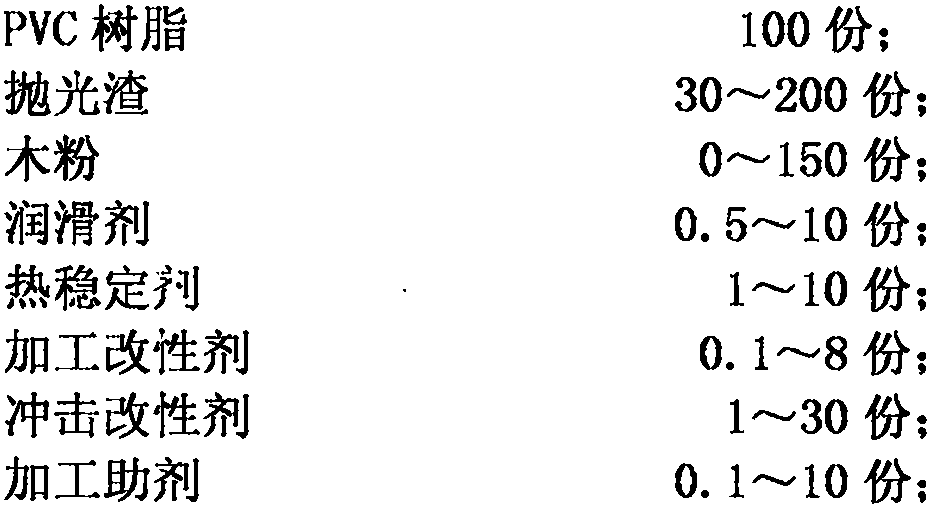

[0049] The various raw material formulas that make up the flame-retardant PVC wood-plastic profile are weighed according to the following mass fractions respectively, and set aside.

[0050]

[0051] Put the PVC resin powder into the high-speed mixer, stir at ...

Embodiment approach 3

[0056] 1. Pretreatment:

[0057] Put the wood powder with a particle size of 60 mesh into the dryer at a temperature of 195°C, heat it for 10 minutes for baking treatment, dry the water and evaporate the impurities. The wood flour after baking treatment is added to a high-speed mixer and heated to 100 ° C, and a titanate coupling agent of 1.5% of the total mass of the wood flour is added, and the titanate coupling agent and chlorinated paraffin are mixed in a ratio of 1:1. Spray on the surface of polishing slag, stir and activate at high speed for 8 minutes; discharge the material into the cold mixer and stir for 10 minutes, discharge after cooling, and obtain activated wood powder.

[0058] 2. Mixing:

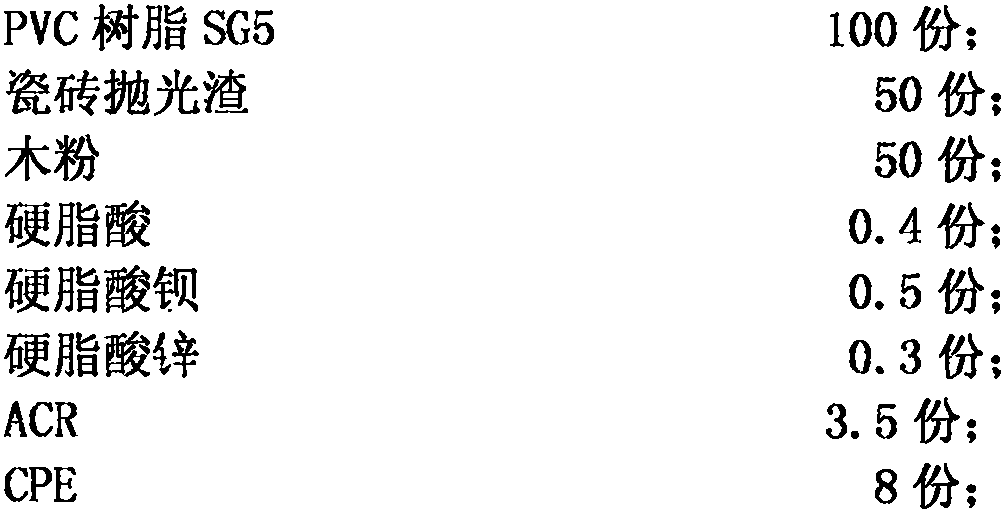

[0059] The various raw material formulas that make up the flame-retardant PVC wood-plastic profile are weighed according to the following mass fractions respectively, and set aside.

[0060]

[0061]

[0062] Put the PVC resin powder into the high-speed mixer, stir at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com