Method for producing porous ceramic with oriented structure by employing freeze dehydration

A freeze-drying method, a technology of porous ceramics, applied in the field of preparing directional porous ceramic materials, can solve the problems of environmental pollution, limited materials suitable for the process, difficult to control the pore structure, etc., achieve small sintering shrinkage, realize net size molding, and less organic additives. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

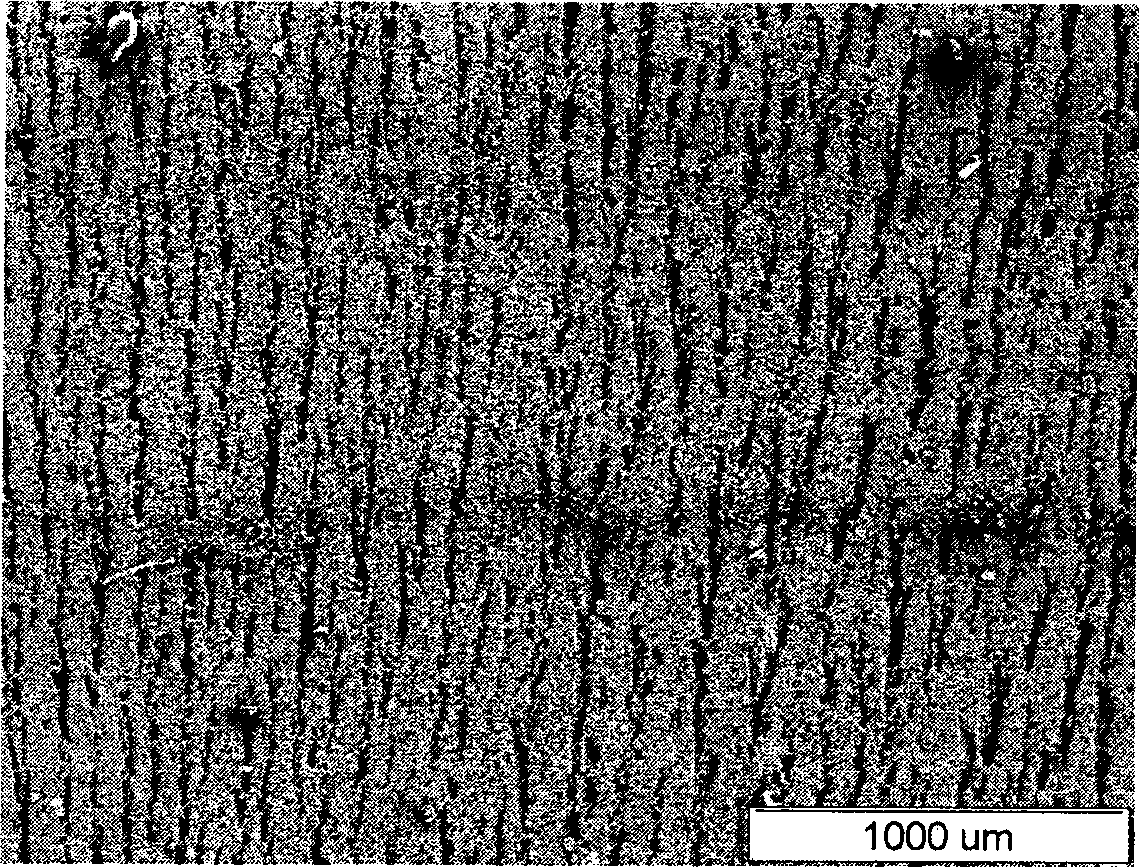

[0019] Preparation of α-Al with Oriented Structure by Freeze-drying 2 o 3 porous ceramic material.

[0020] The raw material used is α-alumina (α-Al 2 o 3 ), the dispersant is ammonium polyacrylate (NH 4 PAA), binder is polyvinyl alcohol (PVA).

[0021] Add 100g of α-Al to the ball mill jar 2 o 3 , 1g of NH 4 PAA, 30.5ml of deionized water, ball milled for 0.5 hours to prepare a slurry; add 5ml of PVA solution to the slurry and adjust the pH to 8.5, mix evenly and inject into the mold, and put it into the freezing medium at -20°C to freeze Freeze in the device for 0.5 hours, take it out, and place it in a vacuum box for 5 hours to obtain the biscuit; put the biscuit into a high-temperature furnace at 1300 ° C, sinter for 1 hour, and cool to room temperature with the furnace temperature to obtain a oriented structure. α-Al 2 o 3 porous ceramic material.

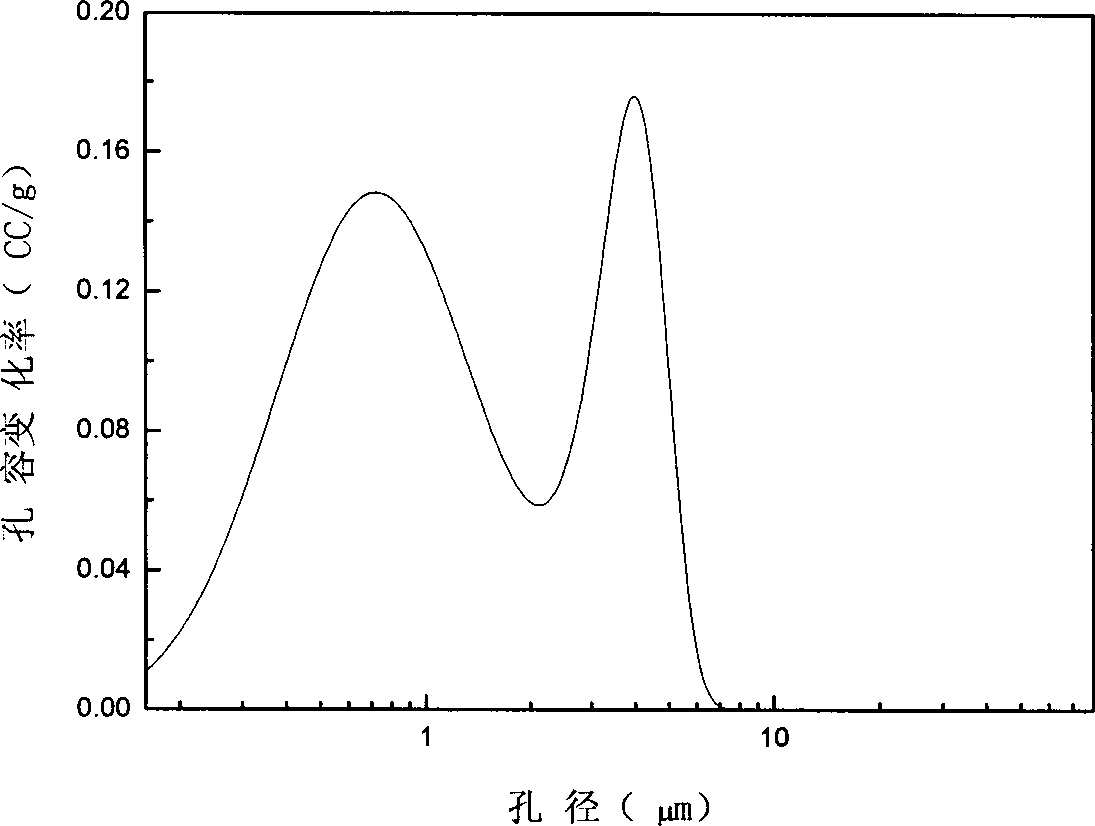

[0022] Determination of α-Al with Oriented Structure by Archimedes Drainage Method 2 o 3 The porosity of the po...

Embodiment 2

[0027] Preparation of α-Al with Oriented Structure by Freeze-drying 2 o 3 porous ceramic material.

[0028] Add 100g of α-Al to the ball mill jar 2 o 3 , 0.5g of NH 4 PAA, 100ml of deionized water, ball milled for 0.5 hours to prepare a slurry; add 5ml of PVA solution to the slurry and adjust the pH to 8.5, mix evenly and inject into the mold, and put the freezing medium temperature into a freezer at -20°C Freeze for 0.5 hours, take it out, and place it in a vacuum box for 5 hours to get the biscuit; put the biscuit in a high-temperature furnace at 1300 ° C, sinter for 1 hour, and cool to room temperature with the furnace temperature to obtain α -Al 2 o 3 porous ceramic material.

[0029] Determination of α-Al with Oriented Structure by Archimedes Drainage Method 2 o 3 The porosity of the porous ceramic material is 75.7%.

[0030] Testing α-Al with Oriented Structure by Material Mechanics Tester 2 o 3 The compressive strength of the porous ceramic material is 0.3MP...

Embodiment 3

[0032] Add 100g of α-Al to the ball mill jar 2 o 3 , 5g of NH 4 PAA, 37.5ml of deionized water, after ball milling for 0.5 hours, prepare a slurry; add 5ml of PVA solution to the slurry and adjust the pH to 8.5, mix evenly and inject into the mold, put into the freezing medium temperature -20 ℃ freezing device Freeze for 0.5 hours, take it out, and place it in a vacuum box for 5 hours to get the biscuit; put the biscuit into a high-temperature furnace at 1550 ° C, sinter for 1 hour, and cool to room temperature with the furnace temperature to obtain α with oriented structure. -Al 2 o 3 porous ceramic material.

[0033] Determination of α-Al with Oriented Structure by Archimedes Drainage Method 2 o 3 The porosity of the porous ceramic material is 40.1%.

[0034] Testing α-Al with Oriented Structure by Material Mechanics Tester 2 o 3 The compressive strength of the porous ceramic material is 160.9MPa.

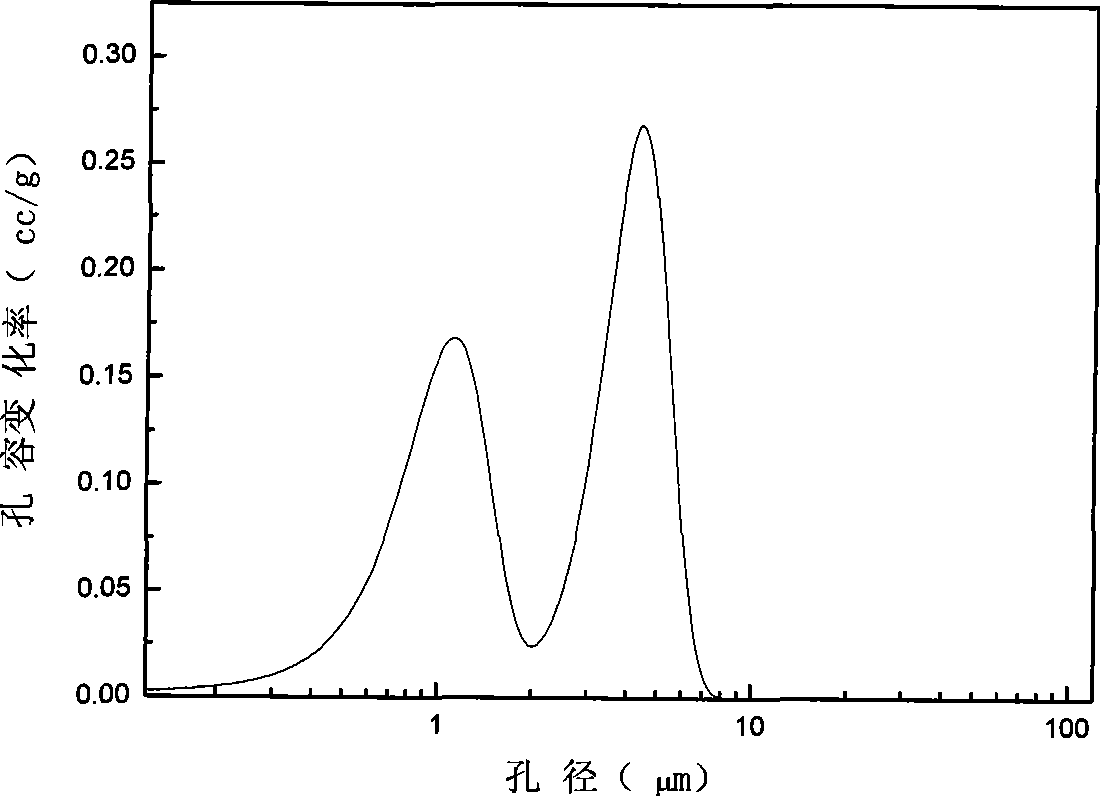

[0035] α-Al with oriented structure prepared by mercury intrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com