Stone sawing machine

A stone sawing machine and saw blade technology, which is applied to stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of stable stone storage, waste of raw materials, and easy cracking of stone flakes, so as to improve work efficiency and reduce production costs , good cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the stone sawing machine of the present invention, a more detailed description will be given below in conjunction with the examples.

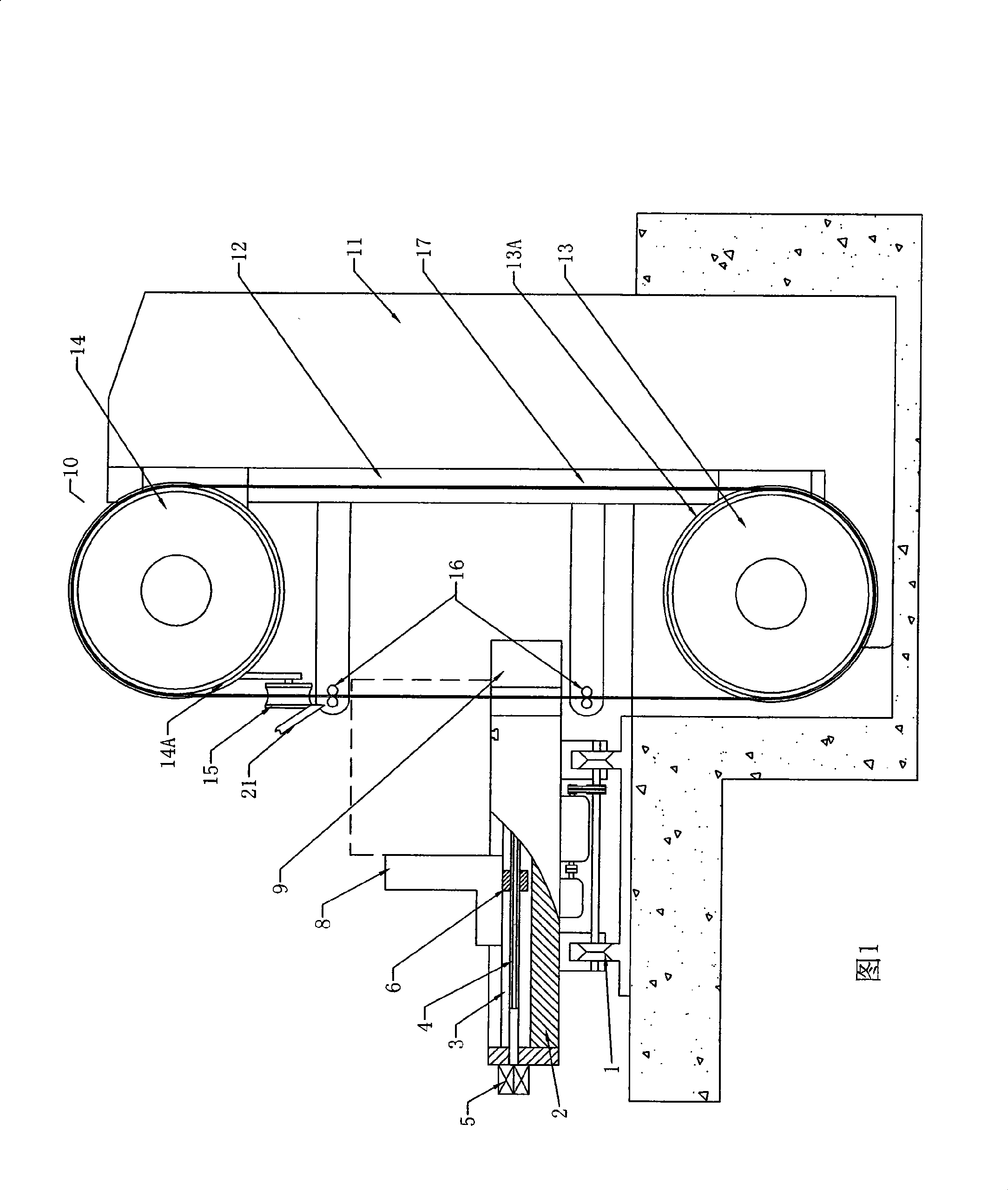

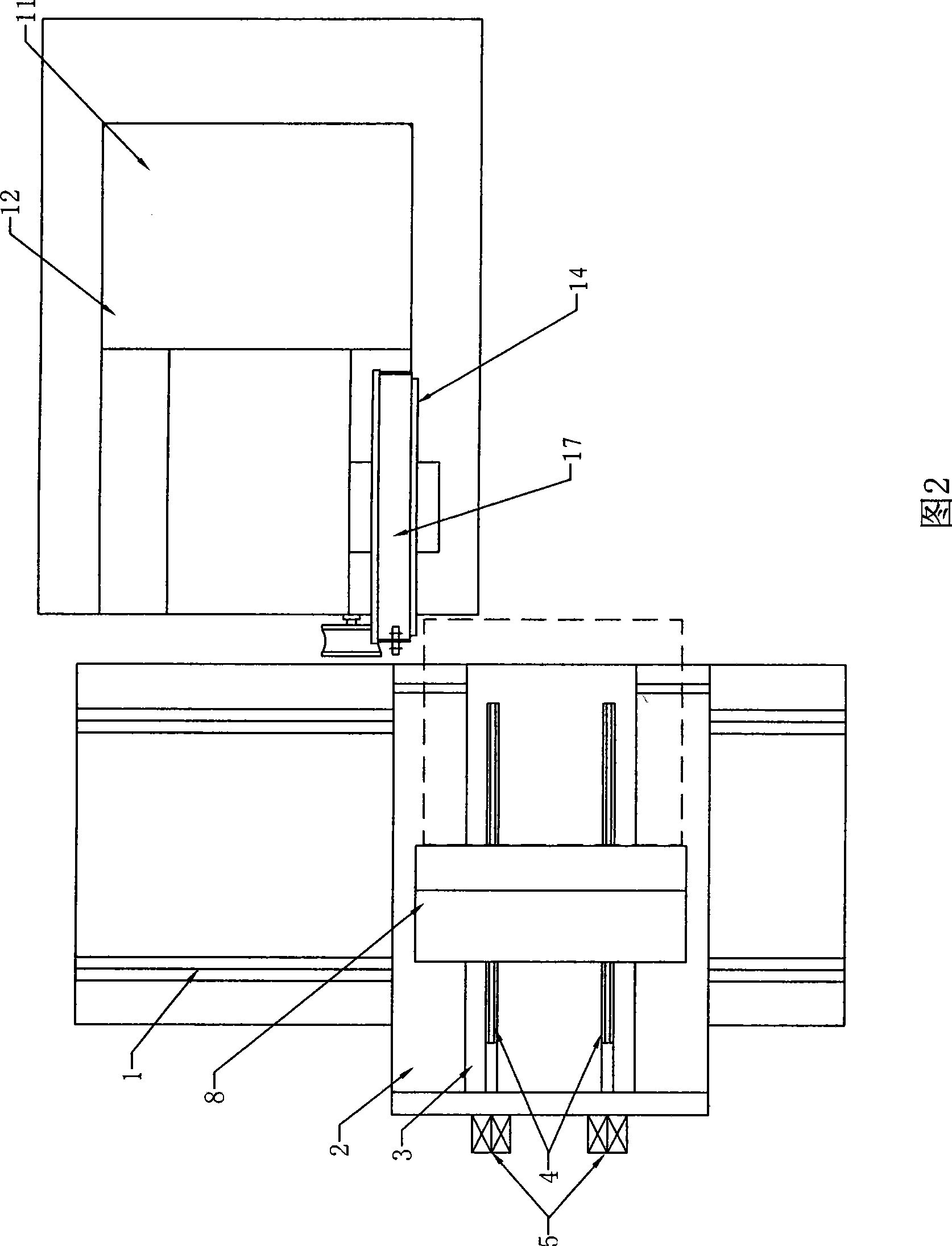

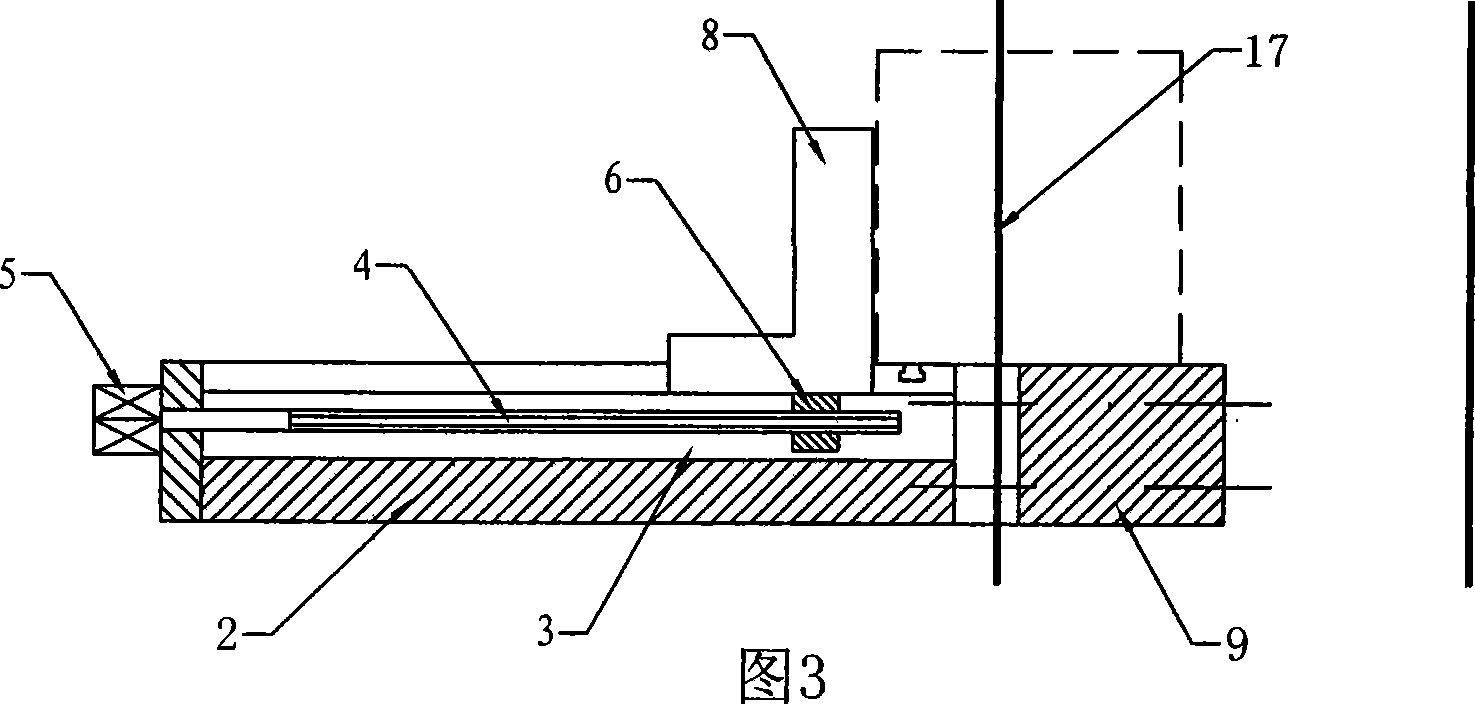

[0020] Fig. 1 is a schematic diagram of the stone sawing machine of the present invention, from which it can be seen that the stone sawing machine of the present invention is mainly composed of a cutting part 10 and a feeding part, wherein the cutting part 10 includes a fixed frame 11, a movable frame 12, and is mounted on a fixed frame. The driving wheel 13 on the frame 11 and the driven wheel 14 installed on the movable frame 12 are composed of the fixed frame 11 directly fixed on the ground. Since the stone is relatively heavy, in order to reduce the lifting of the stone during processing, in fact, usually The fixed frame 11 is placed in a pit on the ground.

[0021] Between the movable frame 12 and the fixed frame 11, the distance therebetween can be adjusted by a jacking device. Tension hangs on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com