Antifriction coatings, methods of producing such coatings and articles including such coatings

A coating, lubricating coating technology, applied in coatings, manufacturing tools, transportation and packaging, that can solve problems such as not excessive lubrication, harmful effects, friction changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

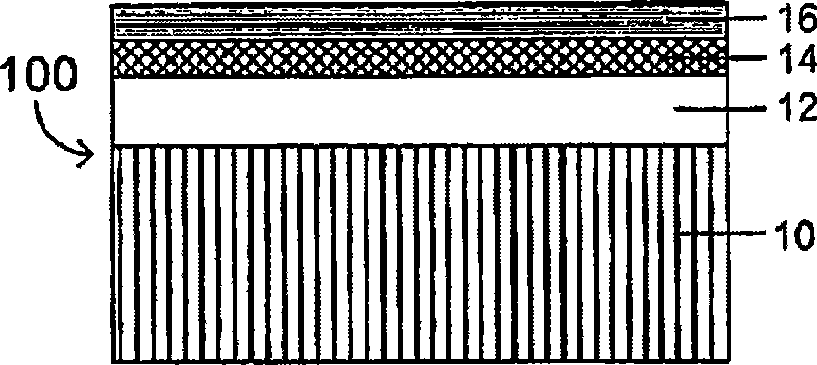

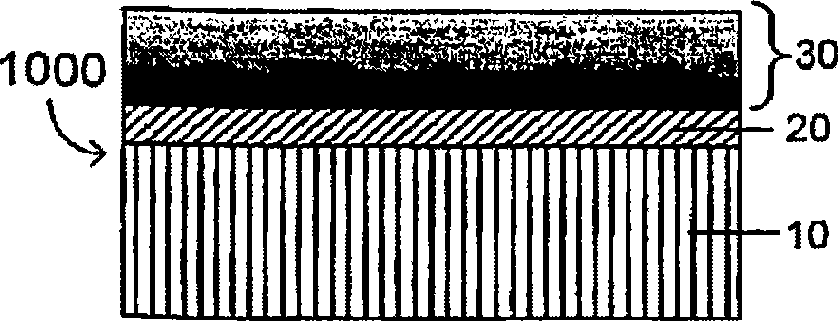

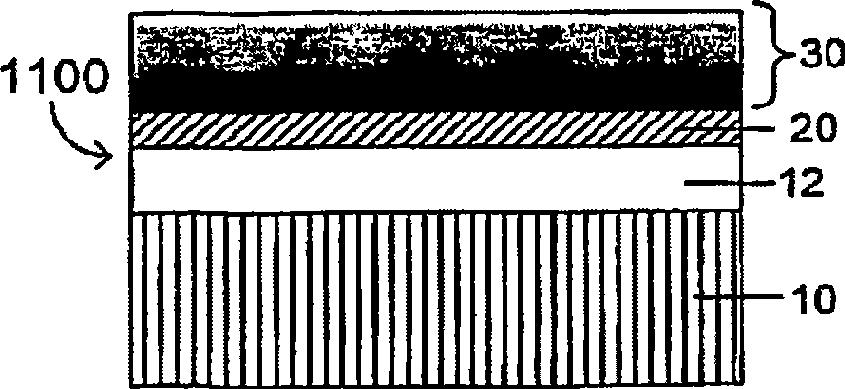

Method used

Image

Examples

Embodiment 1

[0168] The steel battery panels are stripped by 50% hydrochloric acid, rinsed with deionized water, and then in a cyanide-free alkaline zinc dipping solution with a current density of 20 amperes per square inch (ASF) (2.15A / dm 2 ) to achieve a coating thickness of 8 to 10 microns.

[0169] The first panel was immersed in solution A (passivator) for 60 seconds to form a conversion coating, followed by immersion in solution B (corrosion-resistant sealing material) for 60 seconds. This plate is equivalent to applying a layer of sealing resin directly to the conversion film.

[0170] Immerse the second panel in solution A for 60 seconds to form a conversion film, then add 2ml / LFUCHS Immerse in solution B of Gleitmo 605 for 60 seconds. This plate is equivalent to applying a conventional integral lubricating seal coat to the conversion coating.

[0171] The third panel was immersed in the mixture of solution A in which 2.5ml / L Michelman ME 93235 emulsified lubricant had been ad...

Embodiment 2

[0174] 25 unplated bolts in each six-bolt geometry:

[0175] Captive washer bolts from Brogola, part number W701605, model number M8×1.25×25 8.8PC;

[0176] Confinement flange face bolts from SPS Technology, part number N606543, model M8×1.25×309.8PC;

[0177] Flange bolts from Indiana Auto., part number N605790, model M89.8PC;

[0178] Flange bolts from Textron Group, type M10×45 10.9PC;

[0179] Hex head bolts from Wilson Garner, model M10×40 9.8PC; and

[0180] Flange face bolts, type M10×65 8.8PC from Freiburg, Baden, assembled into 18×10 inch plating drums, cleaned, then electroplated with an acidic galvanizing solution to deposit zinc to a thickness of 10 microns layer.

[0181] The bolts were then separated into five groups of five bolts each with a six-bolt geometry, and each group was then subjected to torque tension testing on a Ford WZ 100 equipped with an RS Technologies torque tension device All were processed in one of five different post plate programs.

...

Embodiment 3

[0190] In this example, each 40 M8 9.8PC flange bolt from Indiana Automotive Fasteners, part number N605790, was electroplated in zinc conversion coating by dipping in the following solutions prepared by: Heating to 60°C and standing for 24 hours, then cooling to 130°C for use.

[0191] CrCl 3 50g / l

[0192] Co(NO 3 ) 2 3g / l

[0193] NaNO 3 100g / l

[0194] Oxalic acid 30g / l

[0195] Malonic acid 60g / l

[0196] After the conversion coating is formed, the parts are divided into two groups.

[0197] The first control group was repeatedly immersed in 30ml FUCHS Gleitmo 605 in solution B, and then air spin dried at 82°C for 15 minutes to obtain the desired thickness of the integral seal coat.

[0198] The second group was treated according to one embodiment of the present invention by successively immersing them in solutions containing solution B and 240ml FUCHS respectively. Gleitmo 605, solution B and 120ml FUCHS Gleitmo605, solution B a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com