La doped SrTiO3 base oxide pyroelectric material and preparation method

A technology of thermoelectric materials and oxides, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of high cost, difficult to obtain crystal grains, high energy consumption, etc., and achieve short reaction time, synthesis and molding The effect of short time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

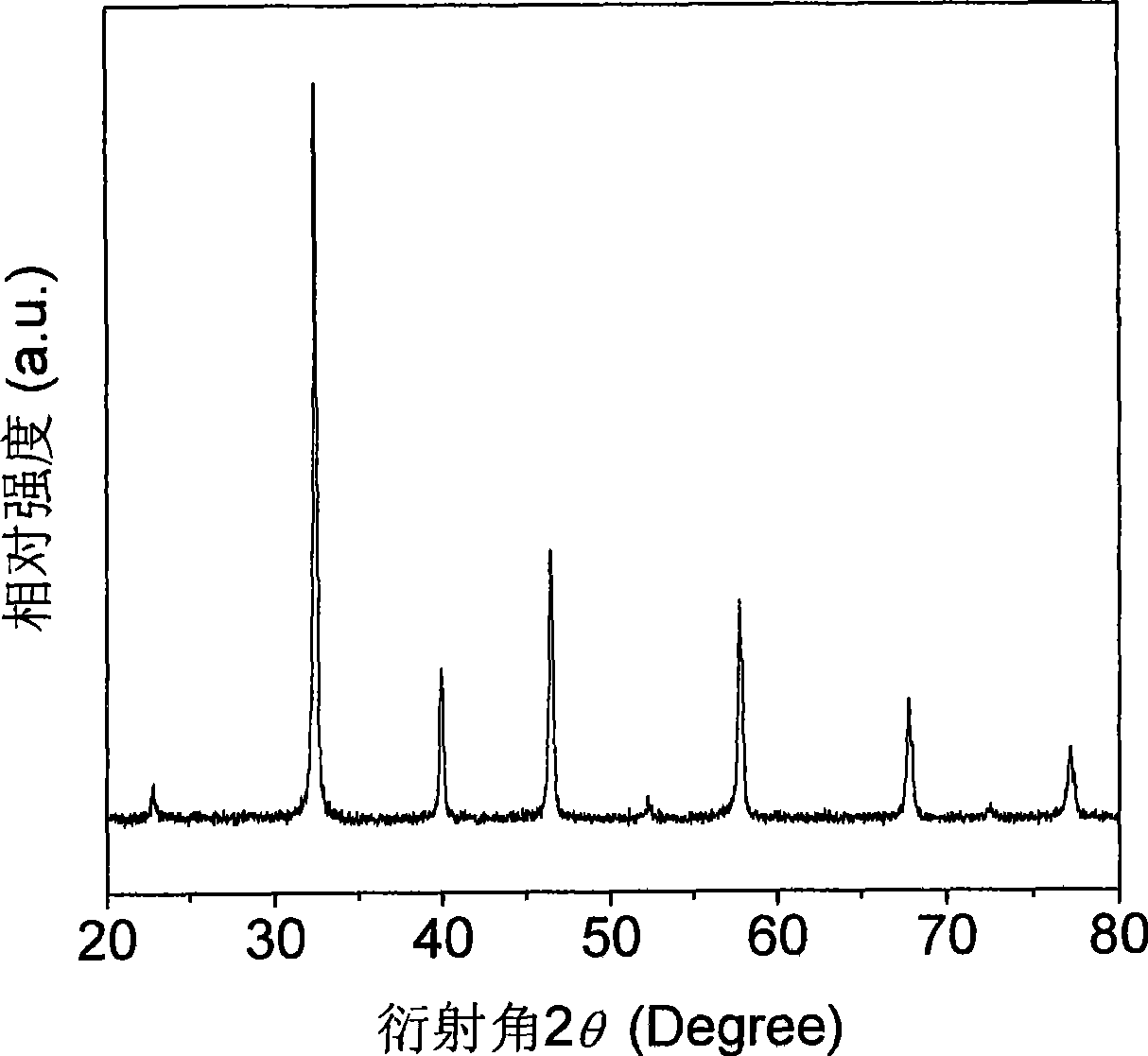

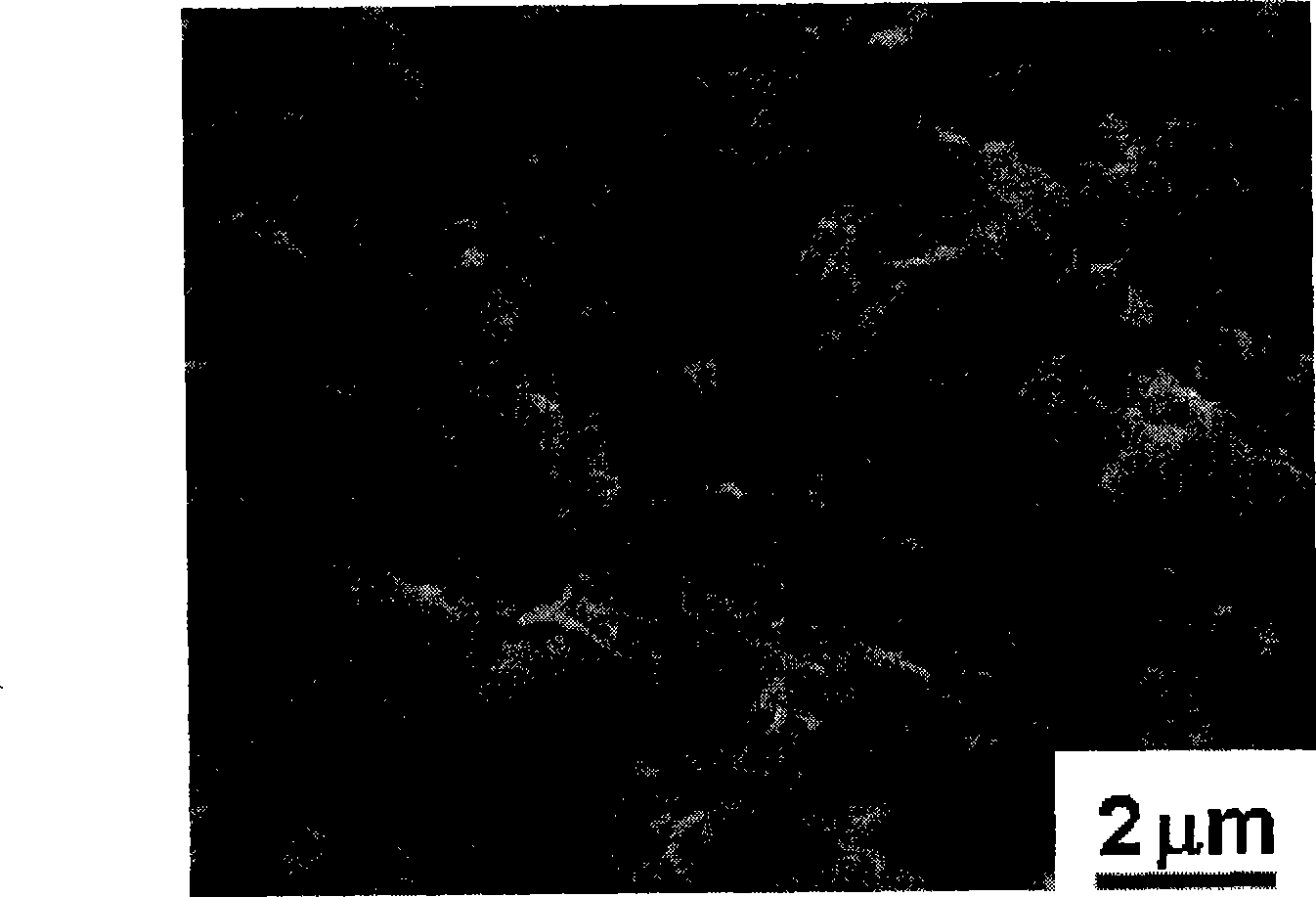

[0026] Accurately weigh 12.5708 grams of Sr(NO 3 ) 2 and 0.2598 g La(NO 3 ) 3 ·6H 2 O, mixed and dissolved in 21.6 mL of deionized water, stirring continuously until a clear solution A was formed. Accurately measure 20.5 ml of Ti(OC 4 h 9 ) 4 , dispersed in 28.0 ml CH 3 CH 2 OH, after mixing well, add dropwise 13.7 ml of CH3 COOH, stirred to obtain a homogeneous transparent solution B. Drop solution A into solution B, and after mixing thoroughly, add 13.1 ml of C dropwise while stirring 3 h 8 o 3 , stirred at 40°C for 1.5 hours, and allowed to stand to form a gel. After the gel was dried at 60°C for 24 hours, it was placed in a box furnace and baked at 500°C for 2 hours to obtain black La 0.01 Sr 0.99 TiO 3 Precursor powder. After the powder is fully ground, put it into a graphite mold with an inner diameter of Φ=10mm, and put it into an SPS furnace with a vacuum of 7Pa, a pressure of 40MPa, a heating rate of 100°C / min, a sintering temperature of 900°C, and a h...

Embodiment 2

[0028] Accurately weigh 12.1899 grams of Sr(NO 3 ) 2 and 1.0392 g La(NO 3 ) 3 ·6H 2 O, mixed and dissolved in 43.2 ml of deionized water, stirring continuously until a clear solution A was formed. Accurately measure 20.5 ml of Ti(OC 4 h 9 ) 4 , dispersed in 56.1 mL of CH 3 CH 2 OH, after mixing well, drop in 27.5 ml of CH 3 COOH, stirred to obtain a homogeneous transparent solution B. Drop solution A into solution B, and after mixing thoroughly, add 21.9 ml of C dropwise while stirring 3 h 8 o 3 , stirred at 60°C for 1 hour, and allowed to stand to form a gel. After the gel was dried at 60°C for 36 hours, it was placed in a box furnace and fired at 560°C for 1 hour to obtain black La 0.04 Sr 0.96 TiO 3 Precursor powder. After the powder is fully ground, put it into a graphite mold with an inner diameter of Φ=15mm, and put it into an SPS furnace with a vacuum of 5Pa, a pressure of 45MPa, a heating rate of 100°C / min, a sintering temperature of 900°C, and a heat ...

Embodiment 3

[0030] Accurately weigh 11.9360 g of Sr(NO 3 ) 2 and 1.5588 g La(NO 3 ) 3 ·6H 2 O, mixed and dissolved in 43.2 ml of deionized water, stirring continuously until a clear solution A was formed. Accurately measure 20.5 ml of Ti(OC 4 h 9 ) 4 , dispersed in 84.1 mL of CH 3 CH 2 OH, after mixing well, drop in 41.2 ml of CH 3 COOH, stirred to obtain a homogeneous transparent solution B. Drop solution A into solution B, and after mixing thoroughly, add 21.9 ml of C dropwise while stirring 3 h 8 o 3 , stirred at 50°C for 0.5 hour, and allowed to stand to form a gel. After the gel was dried at 70°C for 36 hours, it was placed in a box furnace and fired at 530°C for 1.5 hours to obtain black La 0.06 Sr 0.94 TiO 3 Precursor powder. After the powder is fully ground, put it into a graphite mold with an inner diameter of Φ=20mm, and put it into an SPS furnace with a vacuum of 7Pa, a pressure of 45MPa, a heating rate of 100°C / min, a sintering temperature of 930°C, and a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com