Method for preparing phosphorosilicate glass

A technology of phosphosilicate glass and silane, which is applied in the field of preparation of phosphosilicate glass and can solve problems such as unfavorable precise etching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

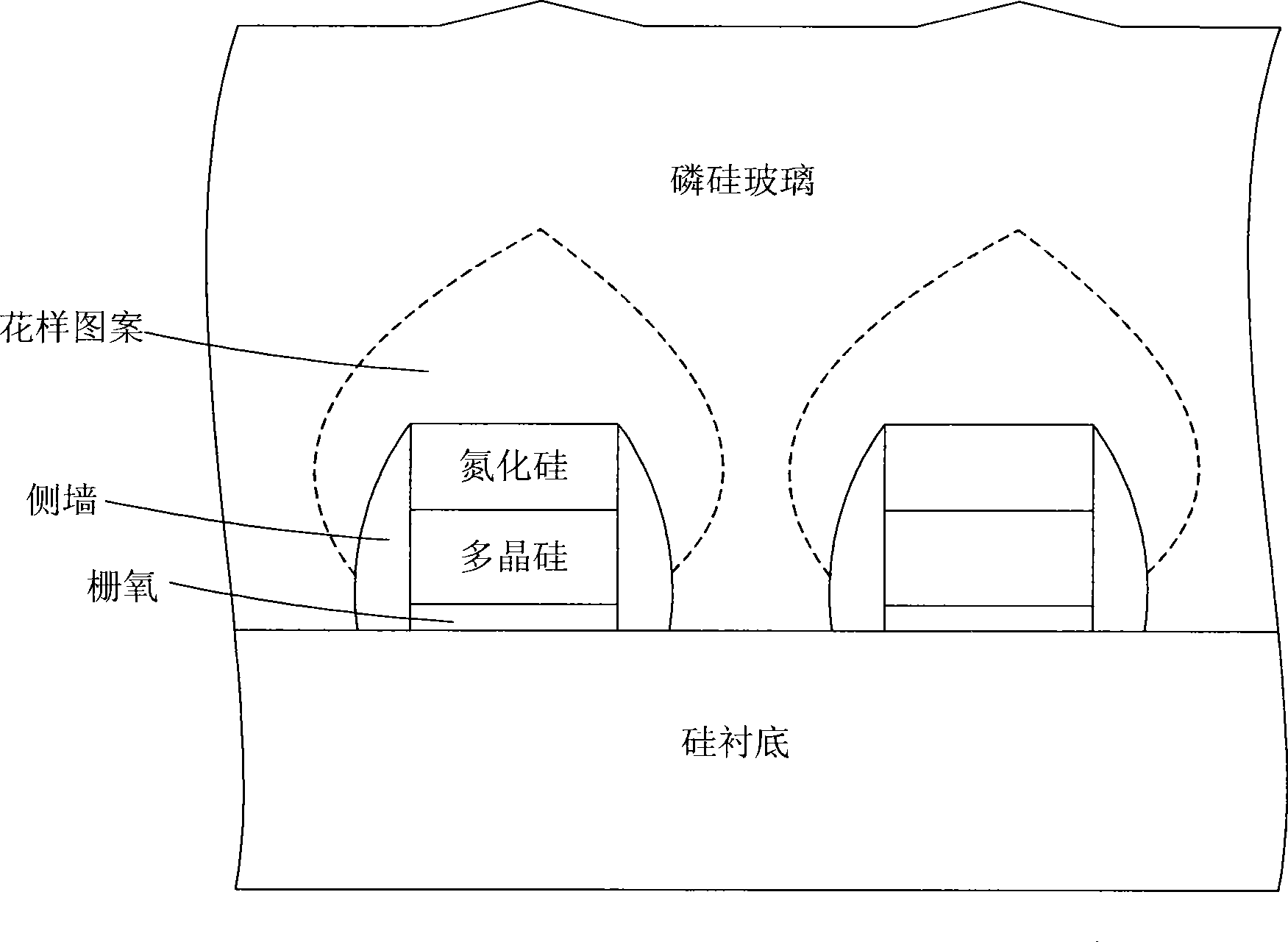

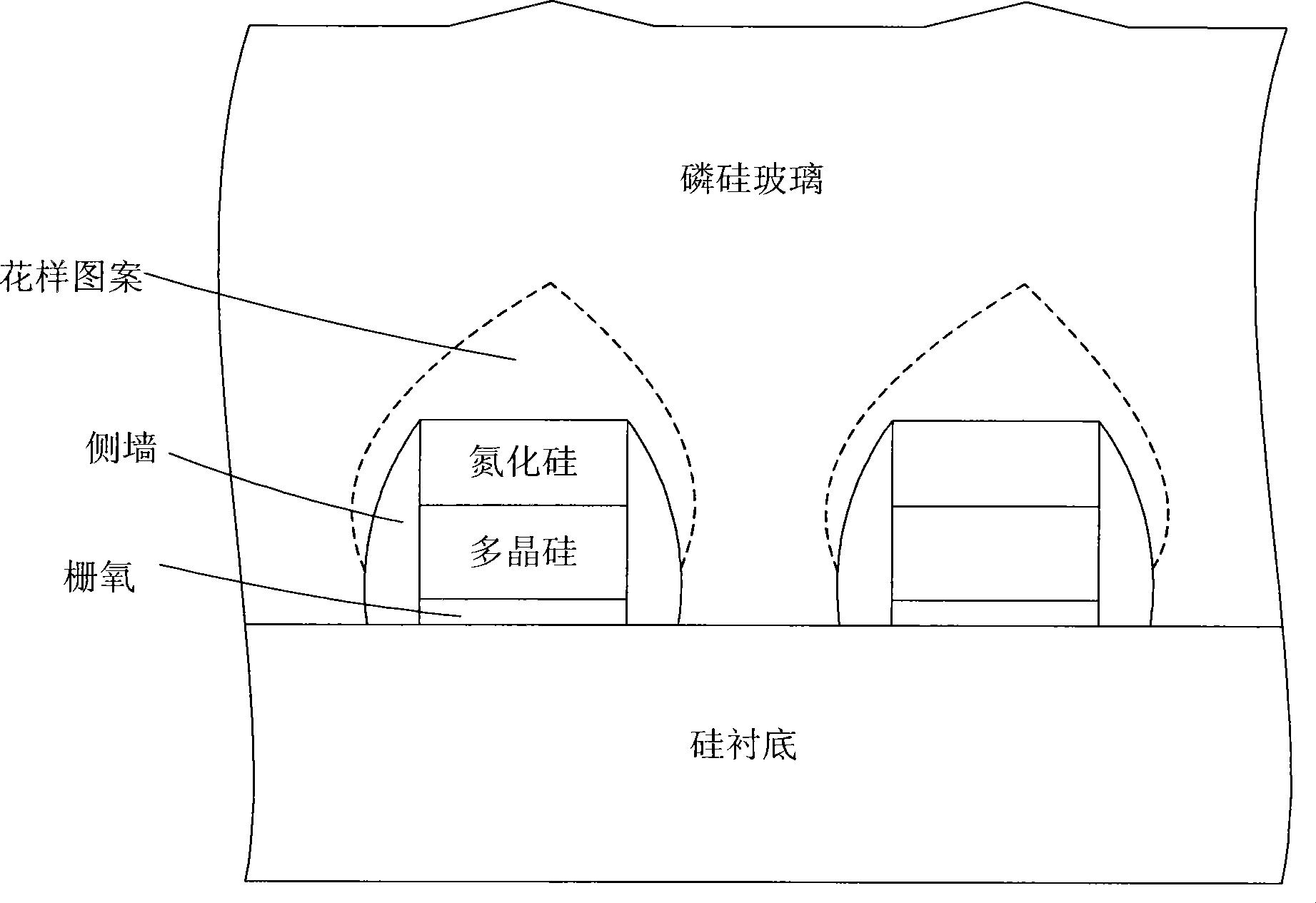

[0011] In the preparation of phosphosilicate glass, it is usually necessary to cover the steps formed by the gate. In the high-density plasma process, there are two phenomena of deposition and sputtering, and the relative ratio of deposition and sputtering in the process (referred to as the deposition-sputtering ratio) can be adjusted by adjusting the process conditions. In the present invention, the deposition of phosphosilicate glass in the high-density plasma process is divided into multiple steps and carried out continuously. In the first step of deposition, the deposition and sputtering ratio is relatively large, and the deposition and sputtering ratio can be controlled at 5.7~ Between 6.7, the adjustment of the deposition sputtering ratio can be adjusted by the reactive gas silane (SiH 4 ) to control the total amount, the power and pressure in general deposition cannot be easily changed. increase SiH 4 The flow rate can significantly increase the deposition sputtering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com