Preparation method of tobacco extractum and use thereof

A technology of tobacco extract and tobacco powder, which is applied in the field of preparation of tobacco extract, can solve the problems of high cost and high difficulty in industrial production, and achieve the effects of low production cost, low price and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

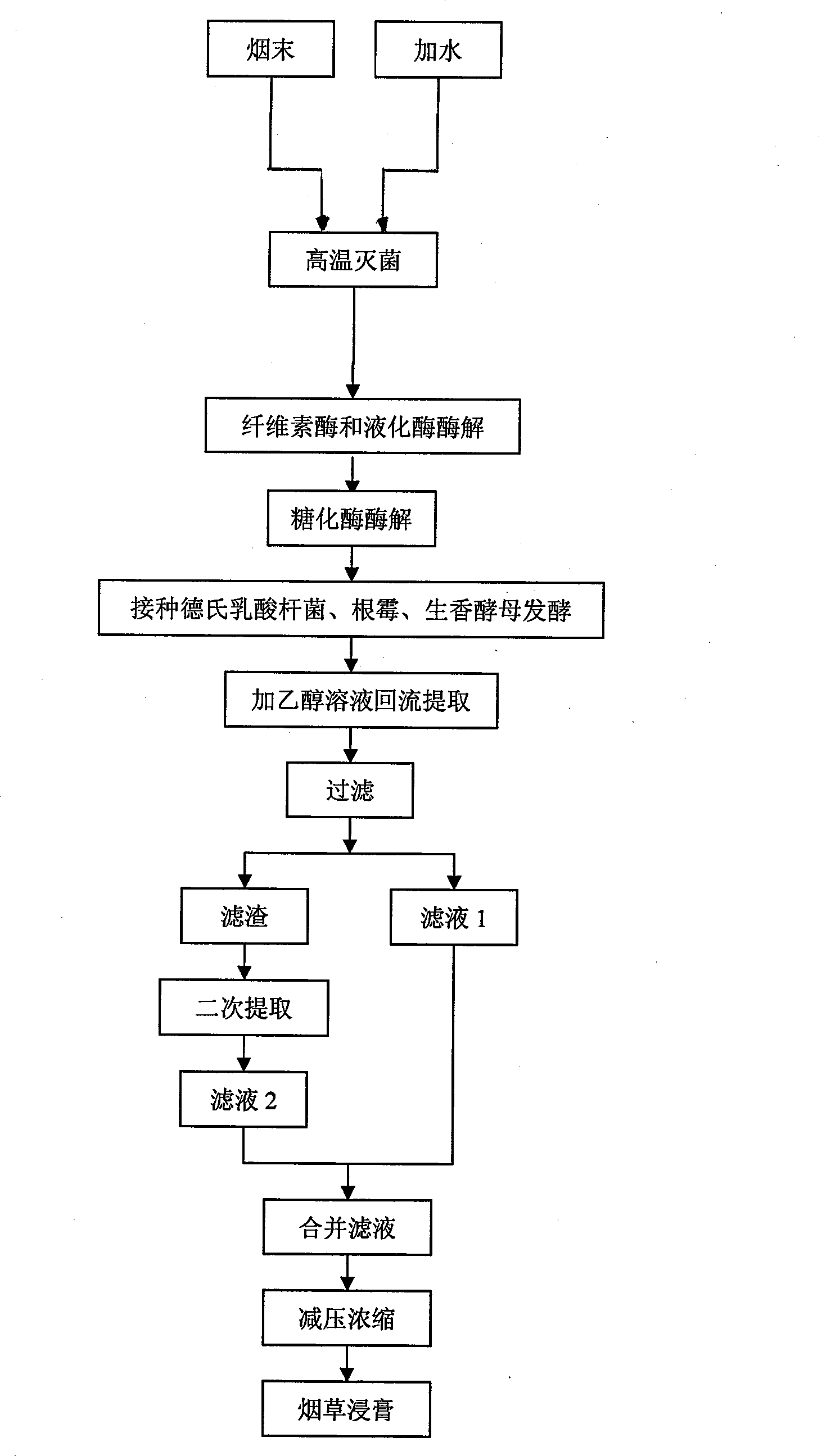

Method used

Image

Examples

Embodiment 1

[0027] Weigh 30g of tobacco powder into a 500mL triangular flask, add distilled water at a solid-to-liquid ratio of 1:5, wrap the mouth of the bottle with gauze, and sterilize and cook for 30 minutes in steam at 100°C in a sterilizing pot.

[0028] Adjust the pH value to 6.0, respectively add cellulase with a weight of 2‰ of tobacco dust and liquefaction enzyme with a weight of 5‰ of tobacco dust, and react in a constant temperature water bath shaker at 50°C and 150r / min for 4h.

[0029] Adjust the pH value to 4.5, add 1% glucoamylase by the weight of tobacco powder, and react at 50° C., 150 r / min in a constant temperature water bath shaker for 3 hours.

[0030] Inject the corresponding strain seed solution into the enzymatic hydrolyzate after the enzyme treatment in proportion, and cultivate it in a constant temperature shaker at 30°C and 120r / min for 3 days. (Lactobacillus delbrueckii inoculation amount 1%; Rhizopus inoculum amount 3%, Aroma yeast inoculum amount 1%)

[003...

Embodiment 2

[0036] Weigh 30g of tobacco powder into a 500mL triangular flask, add distilled water at a solid-to-liquid ratio of 1:7, wrap the mouth of the bottle with gauze, and sterilize and cook in steam at 100°C for 40 minutes in a sterilizing pot.

[0037] Adjust the pH value to 7.0, respectively add cellulase with a weight of 5‰ of tobacco dust and liquefaction enzyme with a weight of 3‰ of tobacco dust, and react in a constant temperature water bath shaker at 60°C and 150r / min for 2h.

[0038] Adjust the pH value to 8.0, add 2% glucoamylase by weight of tobacco powder, and react at 70°C and 150r / min constant temperature water bath shaker for 1.5h.

[0039] Inject the corresponding strain seed solution into the enzymatic hydrolyzate after the enzyme treatment in proportion, and cultivate it in a constant temperature shaker at 50°C and 120r / min for 3 days. (Lactobacillus delbrueckii inoculum 2%; Rhizopus inoculum 1%, Aroma yeast inoculum 2%)

[0040] Take out the fermentation broth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com