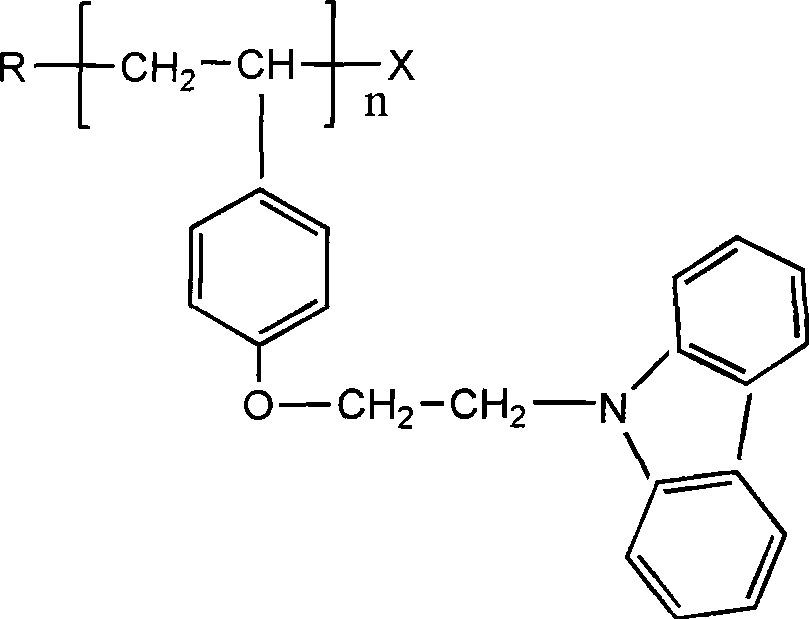

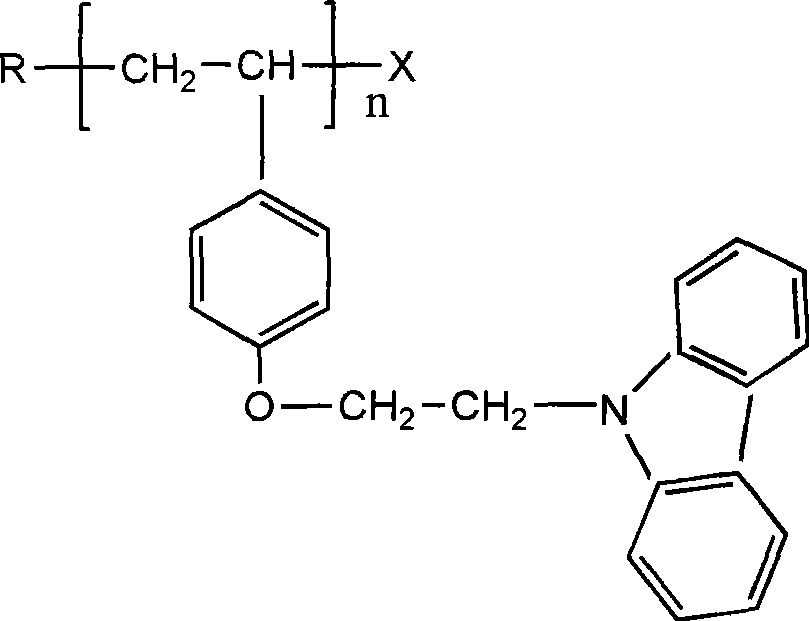

Polymeric / carbon nano-tube composite flash memory material with side chain containing carbazole, synthetic method and use

A carbon nanotube composite and carbon nanotube technology, which is applied in the fields of information and new materials, can solve problems such as unsatisfactory charge transfer, and achieve the effects of improving microscopic compatibility, improving overall performance, and increasing the switching current ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The synthetic method of the macromolecule / carbon nanotube composite flash memory material that side chain contains carbazole, it comprises the steps:

[0035] 1) Treat 10 g of multi-walled carbon nanotube raw material with 100 mL of concentrated sulfuric acid at 80° C. for 24 hours under reflux, and suction filter with deionized water to wash and dry to obtain 7.1 g of acidified carbon nanotubes;

[0036] 2) Add 200 mL of thionyl chloride to 7.1 g of acidified carbon nanotubes, react at 70°C for 24 hours, wash with suction filtration with tetrahydrofuran, and dry to obtain 6.9 g of acylated carbon nanotubes;

[0037] 3) 6.9g of acylated carbon nanotubes were reacted with 150mL of ethylenediamine at 100°C for 48h, suction filtered and washed with tetrahydrofuran, washed and dried to obtain 5.6g of carbon nanotubes with amine groups on the surface;

[0038] 4) Disperse 5.6g of carbon nanotubes with amine groups on the surface and 4.2g (23.38mmol) of triethylamine in 150mL...

Embodiment 2

[0044] The solvent methylene chloride was substituted for toluene, and the others were the same as in Example 1 to obtain 1.28 g of a black composite flash memory material, which corresponds to a graft copolymerization rate of 56% with carbon nanotubes.

Embodiment 3

[0046] The solvent nitromethane was substituted for toluene, and the others were the same as in Example 1 to obtain 1.24 g of a black composite flash memory material, which is equivalent to a graft copolymerization rate of 48% with carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com