Magnetically encoding thin-film material and fabrication method therefor

A technology of magnetic coding and thin film material, applied in the direction of magnetic films, magnetic layers, magnetic objects, etc., can solve the problems of being too simple and the detection signal does not have clear directional requirements, so as to reduce the thickness, eliminate the hidden dangers of environmental protection, and improve the anti-counterfeiting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

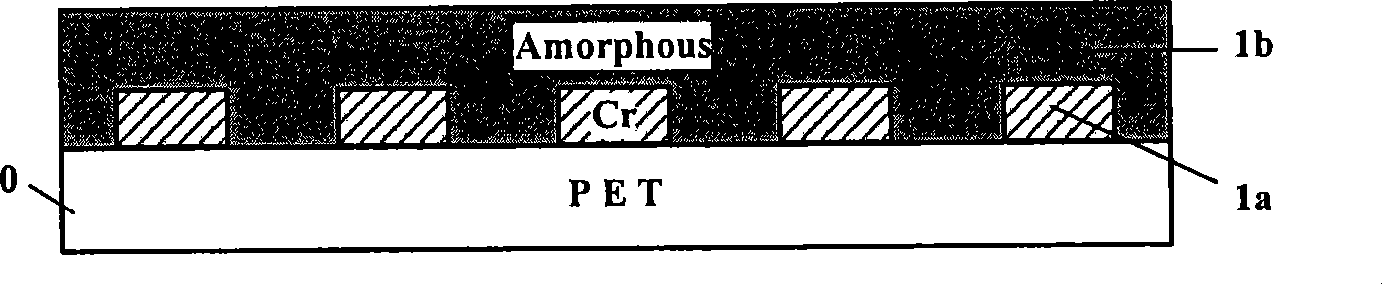

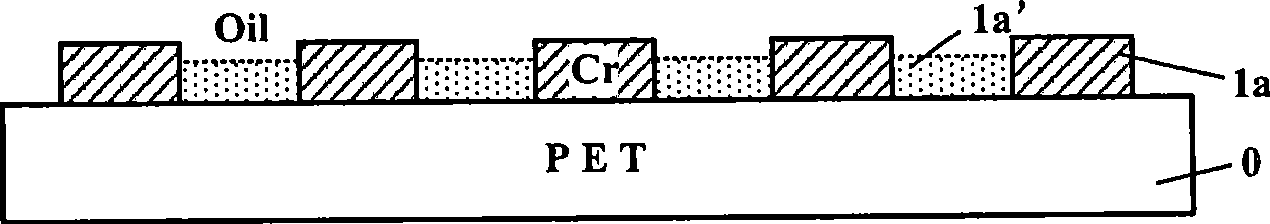

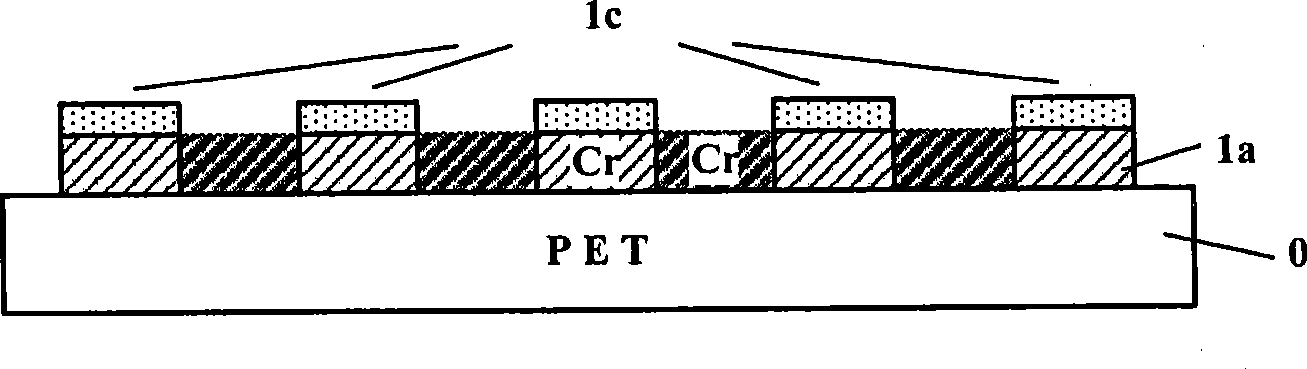

[0057] Preparation of Seed Layer by Oil Mask Evaporation Deposition

[0058] The oil is heated to form oil vapor, which is sprayed on one side of the base layer 0 through a pre-designed microporous mask device to form a certain coding pattern. Then, utilize evaporation deposition equipment to carry out the preparation of seed layer (substrate layer), in deposition process, oil layer is evaporated, forms certain oil vapor area on the surface of oil layer, and the metallic element chromium of seed layer (substrate layer) 1a can only be deposited in the absence of In the area of oil layer, in the area 1a' with oil layer, it cannot deposit and grow, forming a blank area, and finally forming a certain concave-convex coding pattern, such as figure 2 and 5 shown.

Embodiment 2

[0060] Preparation of seed layer by demetallization after deposition of metal layer

[0061] 1. Mask photolithography

[0062] First, a metal chromium layer is evaporated and deposited on one side of the base layer, and then a layer of photosensitive material is coated on the surface of the metal chromium layer. The photosensitive material is mainly composed of a photosensitive agent (such as: ammonium dichromate) and a colloid (such as: gum arabic, Polyvinyl alcohol), using optical exposure technology, the exposure source (such as: visible light, ultraviolet light) through the mask to project the coding pattern onto the photosensitive layer, and then through the development process, using water, anhydrous CaCl 2 , ZnCl 2 and lactic acid and other components to remove the residual glue, and then after baking, use various acid-base corrosion solutions (such as: hydrochloric acid, ferric chloride) or organic solutions to remove unnecessary part of the metal chromium, and finall...

Embodiment 3

[0066] Preparation of the seed layer by depositing a metal layer on top of a water-soluble coating

[0067] First, a layer of water-soluble ink layer 1d with a certain coding pattern is coated on the surface of the base layer, and then a layer of metal chromium layer 1f is deposited on the entire surface of the base layer (including the surface of the water-soluble ink layer). Figure 4 , and finally wash the base layer deposited with the metal chromium layer with water, remove the metal layer deposited on the water-soluble ink layer, and finally form a seed layer (substrate layer) 1a with a certain concave-convex coding pattern.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com