Graphite base heatproof and heat insulating material and production technique thereof

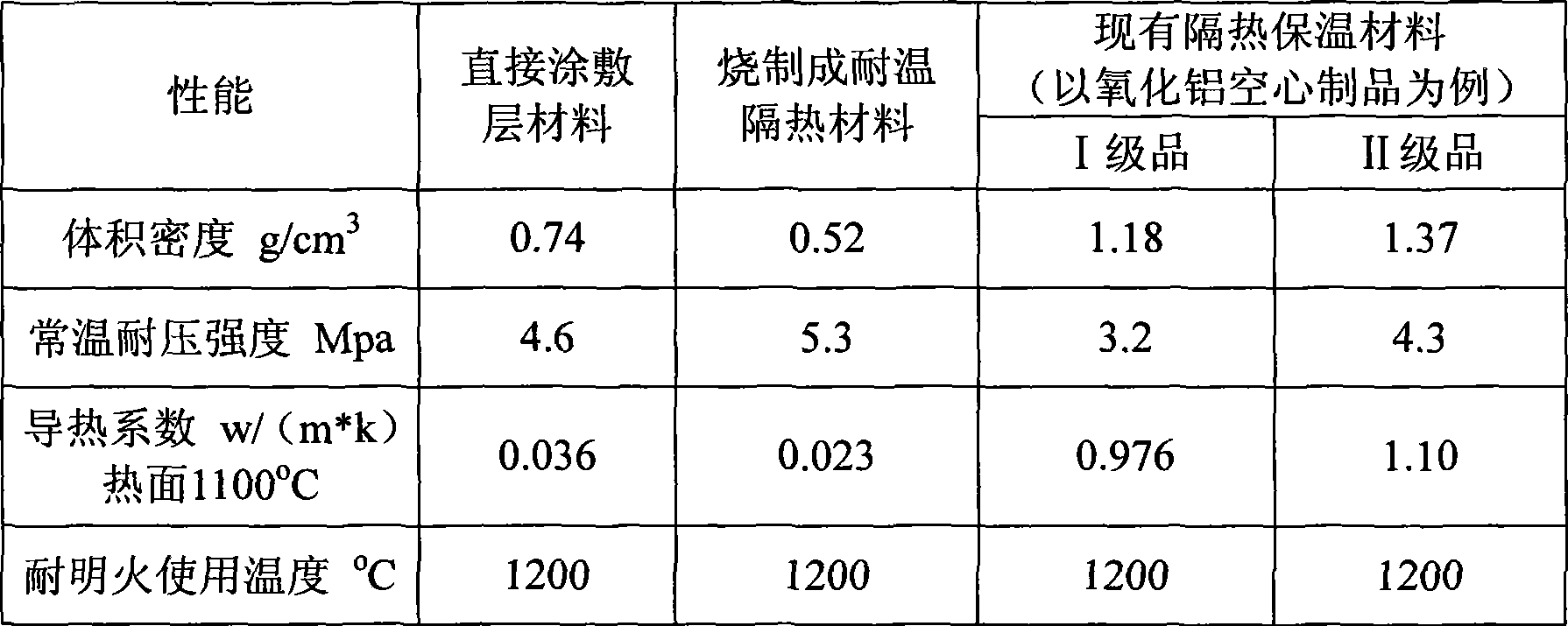

A thermal insulation and production process technology, applied in the field of heat-resistant thermal insulation materials and their preparation, can solve the problems of difficult wall integration, large skin irritation, short service life, etc., and achieve simple process and high volume density The effect of small, good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: An example of sintering and preparing graphite-based heat-resistant and heat-insulating materials.

[0033] (1) Ingredients: graphite powder 22wt%, sepiolite 20wt%, sodium bicarbonate 10wt%, magnesium chloride 14wt%, high-quality aluminate cement 30wt%, auxiliary agent methylcellulose 4%;

[0034] (2) Mixing: Add the above materials into a forced mixer and stir evenly. Based on the total weight of the above materials, add 30wt% of water, mix for 3 minutes, then add 4wt% of water, mix for 5 minutes, and discharge when completely mixed. stand-by;

[0035] (3) Forming: According to the required specifications, adobes of various shapes are made;

[0036] (4) Drying: the shaped bricks are naturally dried on a drying plate, and when the residual moisture is lower than 5wt%, they are put into a blast oven for drying, and when the moisture is less than 3wt%, they are poured into a muffle furnace;

[0037] (5) Firing: Control the heating temperature to be 280°C; ...

Embodiment 2

[0039] Embodiment 2: An example of applying graphite-based temperature-resistant and heat-insulating materials to a temperature-resistant and heat-insulating composite wall.

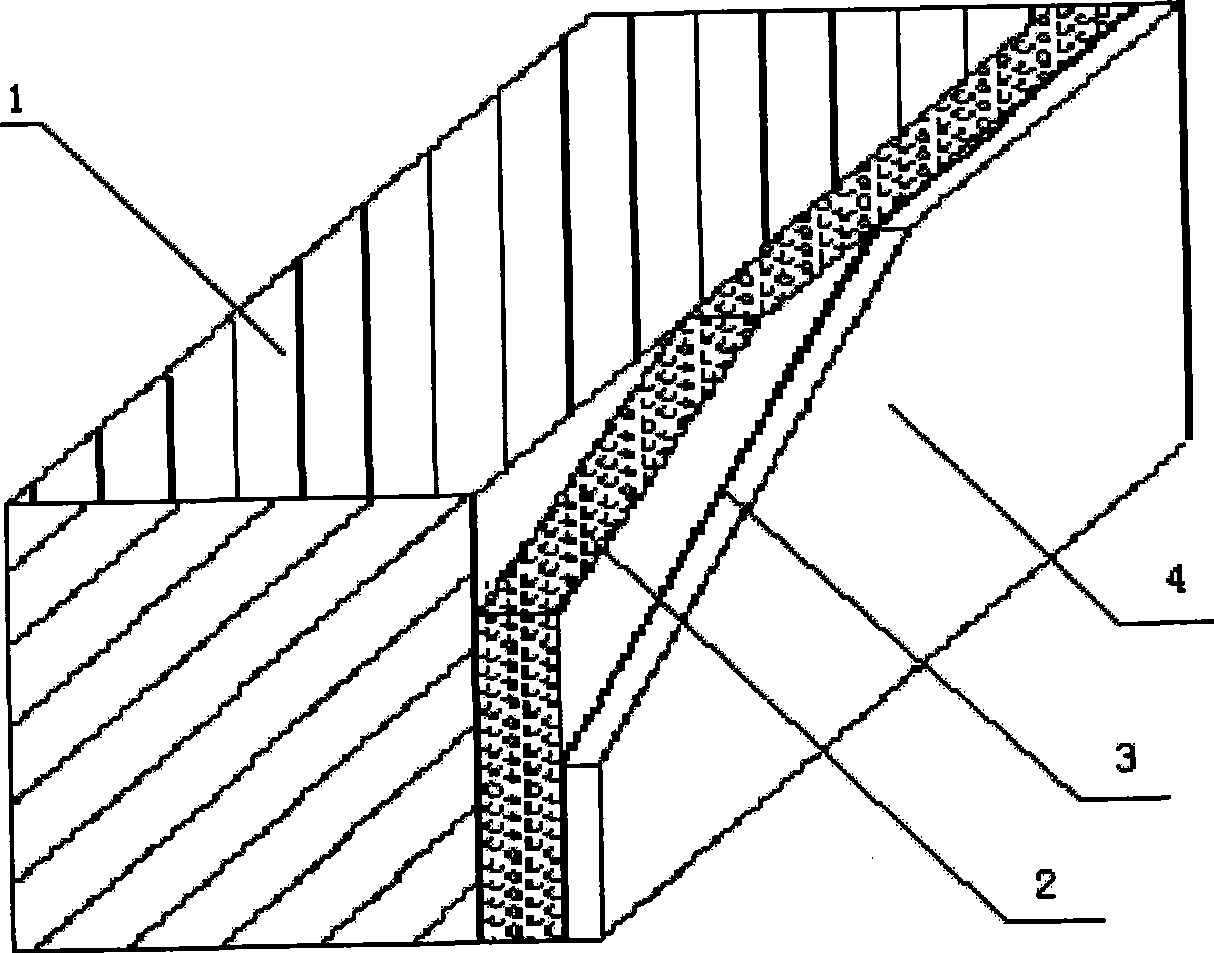

[0040] exist figure 1 In , the wall structure after applying graphite-based heat-resistant and heat-insulating materials to the heat-resistant and heat-insulated composite wall is given. From the inside to the outside, it is the base wall layer 1, the new graphite-based heat-resistant and heat-insulating material 2, the cement mortar protective layer 3, and the decorative surface layer 4.

[0041] Specific steps are as follows:

[0042] (1) Ingredients: graphite powder 28wt%, sepiolite 24wt%, magnesium chloride 15wt%, high-quality Portland cement 28wt%, auxiliary agent hydroxyethyl cellulose 5%;

[0043] (2) Mixing: Put the raw materials into the mixer and mix evenly, add water 35wt% (by weight of the mixture), mix for 3 minutes, then add 5% water and mix evenly before unloading;

[0044] (3) Coating:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com