Base steel composite material for seamless steel pipe top and preparation method thereof

A seamless steel pipe and composite material technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems affecting the service life of the plug and product qualification rate, surface scale peeling, longitudinal cracking, etc., to achieve excellent resistance Oxidation and high temperature performance, long service life, good effect of high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

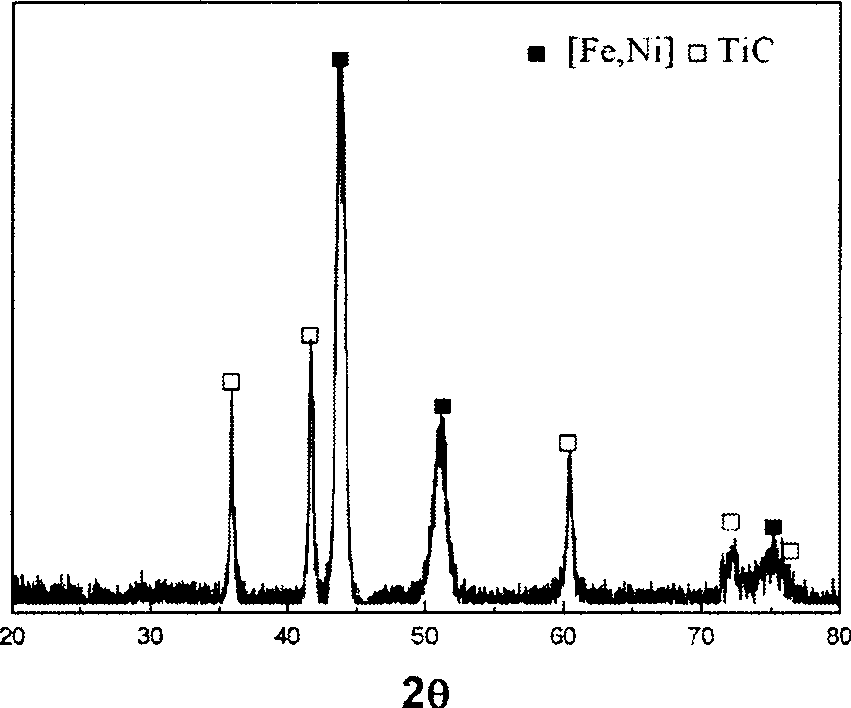

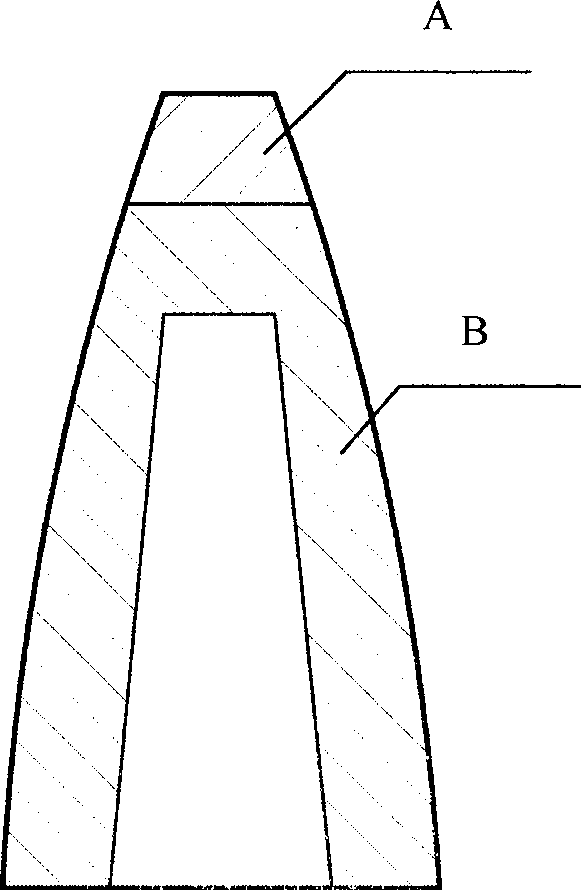

[0027] A steel-based composite material for the plug of a seamless steel pipe machine, which uses the combustion synthesis chemical reaction in the negative pressure casting mold cavity to form a TiC ceramic-metal reinforced area with a thickness of 15 to 20 mm at the front nose of the plug; The bond between the ceramic reinforced area and the plug is a metallurgical bond.

[0028] A method for preparing a steel-based composite material for a seamless steel pipe machine head, the specific process steps are as follows:

[0029] Ti powder, C powder and Ni powder with particle size less than 50 microns, and the ratio of Ti powder and C powder is Ti:C=1:1 by molar ratio, Ni content weight percent is respectively 20%, 30% and 40% Put the reactant powder into the ball mill mixer and mix the material for 5-8 hours to make it evenly mixed; then put the powder into the mold and press it into a compact at room temperature, the compaction rate of the compact is 70±5% ; Then put the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com