LCD substrate, LCD and manufacturing method

A technology of a liquid crystal display and a manufacturing method, which is applied in the field of thin film transistor liquid crystal displays, can solve the problems of fracture, too large interlayer end difference, and the transparent pixel electrode cannot be normally turned on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

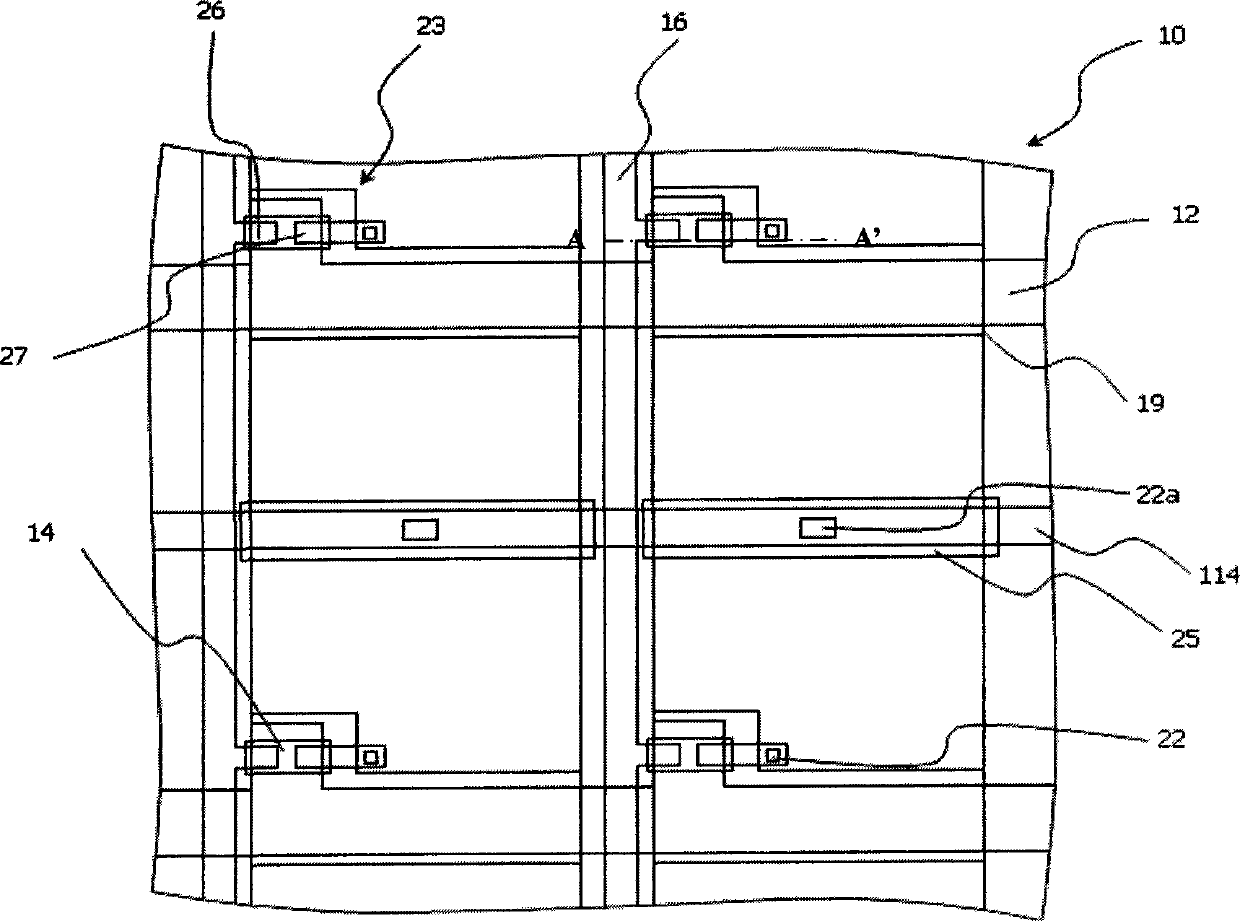

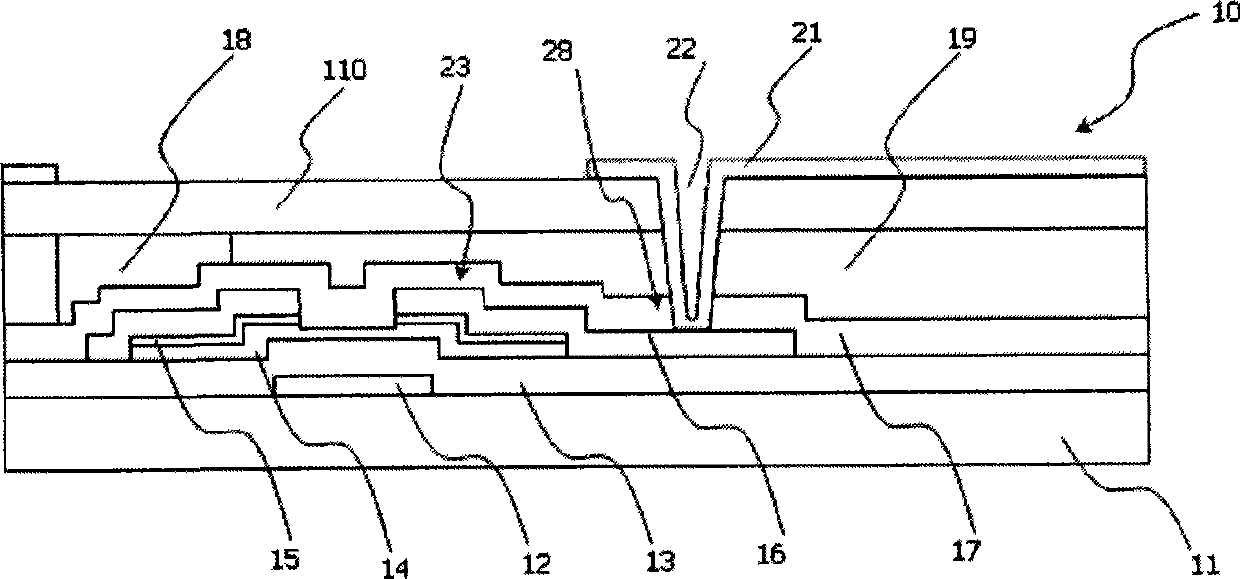

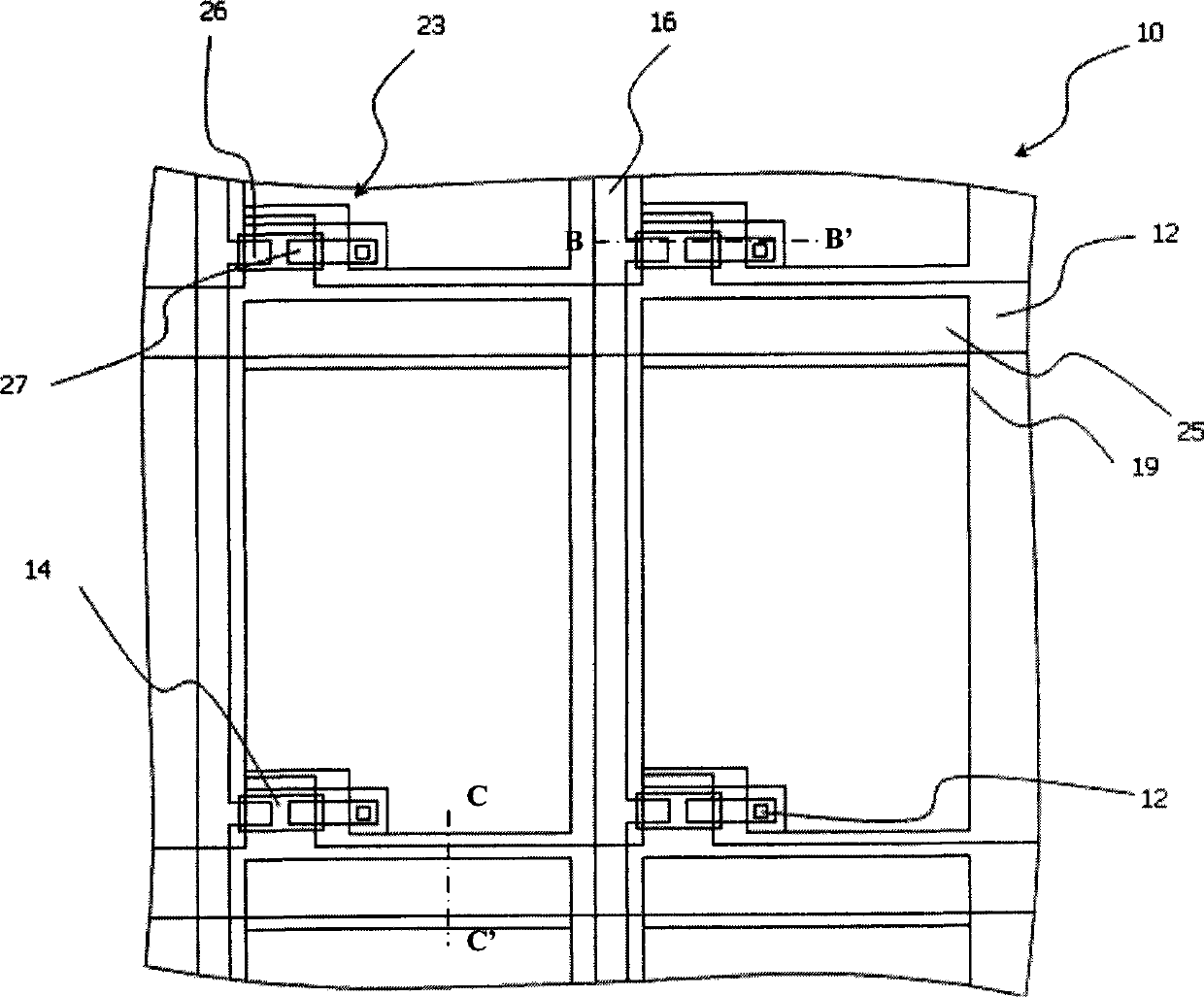

[0050] image 3 Is a top view of the pixel area of the liquid crystal display substrate of the present invention; Figure 4 Yes image 3 Sectional view of B-B’; Figure 5 Yes image 3 Sectional view of C-C’. Such as image 3 , Figure 4 with Figure 5 As shown, the TFT substrate 10 of the present invention specifically includes: forming an aluminum alloy containing one or more of neodymium, silicon, copper, antimony, tungsten, tantalum, and scandium on a glass substrate 11, and forming an aluminum alloy on the glass substrate 11. A plurality of gate lines or gate electrodes 12 formed by laminating high melting point metals such as titanium, chromium, and molybdenum. An insulating gate insulating layer 13 made of oxide, nitride or oxynitride compound (such as SiNx) is formed thereon, and a data line 16 made of high melting point metal is formed by crossing the gate insulating layer 13 with the gate line. The area divided by the gate line 12 and the data line 16 forms a pixel are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com