Piezoelectric ceramic complexes

A technology of piezoelectric ceramics and composites, applied in circuits, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., to achieve the effect of small dielectric constant-temperature coefficient and high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] CaCO 3 , SrCO 3 、 Bi 2 o 3 、TiO 2 (analytical pure) as raw material, according to Sr 2-x Ca x Bi 4 Ti 5 o 18 Stoichiometric weighing, according to the conventional solid-phase synthesis method for batching, ball milling and mixing for 4 hours, drying, 850 ° C heat preservation for 2 hours pre-synthesis, fine grinding, drying, adding binder, molding, plastic discharge (850 ° C, time 2 hours), sintering at 1160°C for 2 hours, and the bismuth layered ceramic composite with the above formula is formed. Its main performance parameters are listed in Table 1. It can be seen from Table 1 that the samples composed around x=1 have higher comprehensive performance.

[0027] Table 1: (Sr 2-x Ca x ) Bi 4 Ti 5 o 18 Typical properties of samples

[0028] x 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 Density (g / cm 3 ) 6.50 6.53 6.51 6.42 6.4 6.31 6.35 6.33 % theoretical density 90 91 91 91 91 90 91 92 ε 33 T (100kHz) 390 280 300 ...

Embodiment 2

[0030] Take the composition of x=1, y=0.1-0.4, and add different contents of MnCO in it 3 The sintering temperature is 1150° C., and the others are the same as in Example 1, and the properties are listed in Table 2.

[0031] Table 2: Performance of samples after doping (x=1)

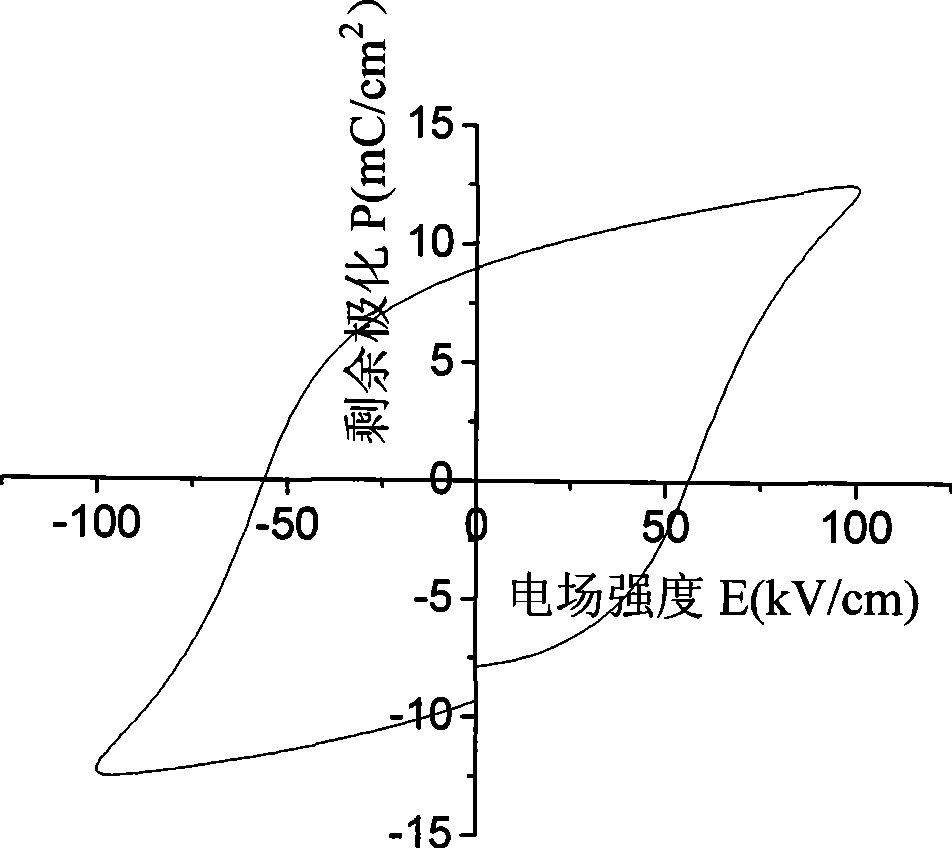

[0032] y 0.1 0.2 0.3 0.4 Density (g / cm 3 ) 6.53 6.50 6.49 6.40 % theoretical density 91 90 91 89 ε 33 T (100kHz) 174 240 215 190 tanδ(100kHz) 0.015 0.01 0.01 0.01 Curie temperature T C

(℃)

572

670

721

650

coercive field

E. c (kV / cm)

60

52

52

52

remanent polarization

2P r (μC / cm 2 ) 18

16

17

14

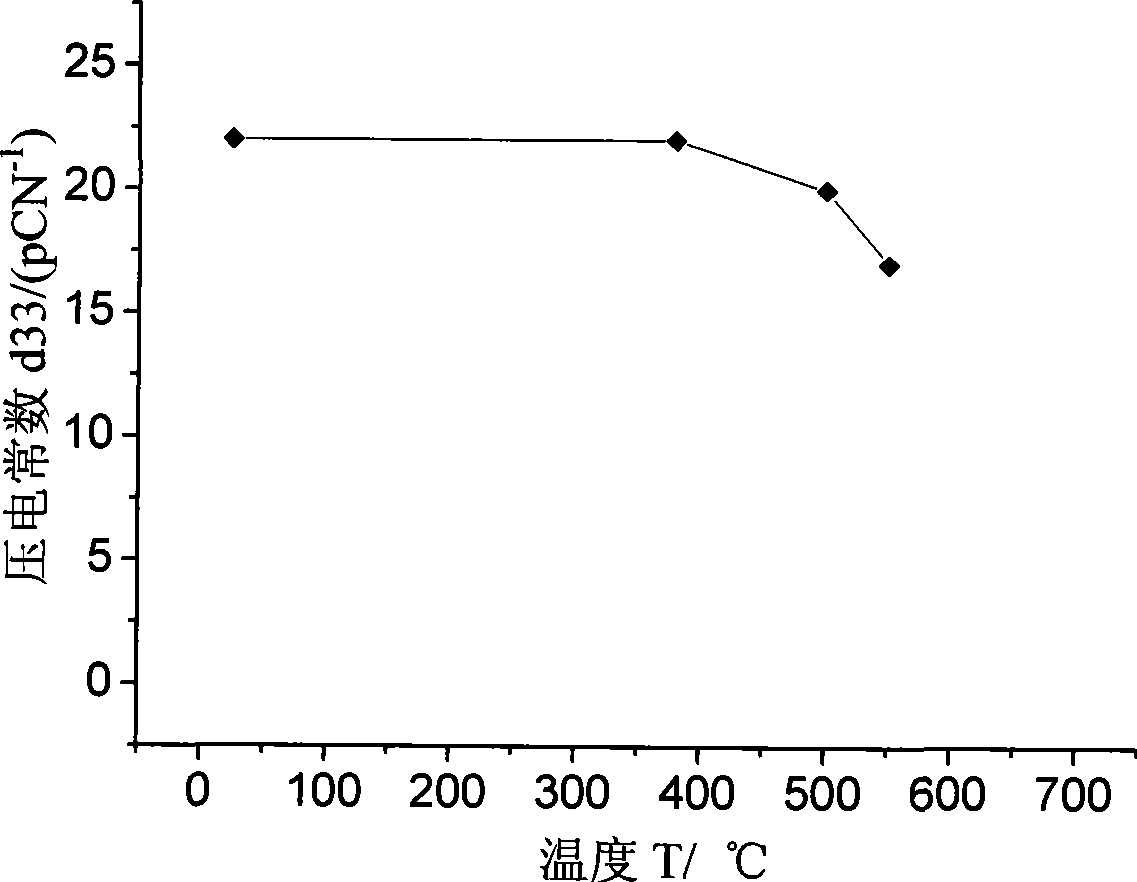

Piezoelectric constant d 33 18 17 15 15

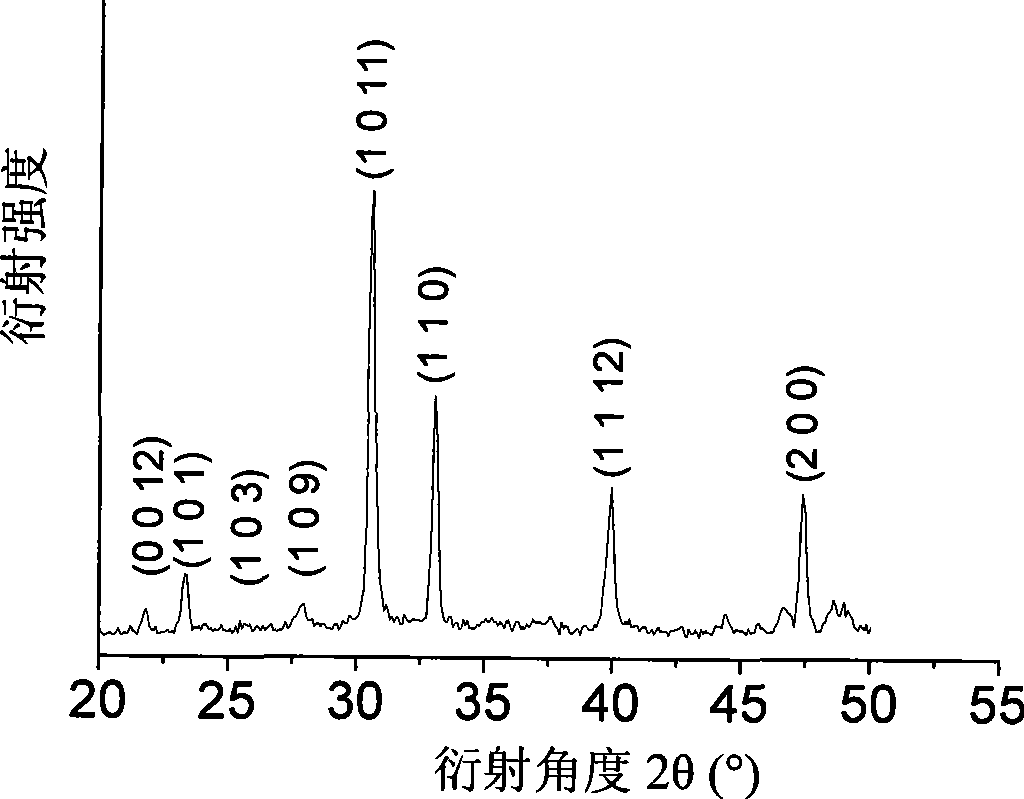

[0033] figure 1 It is a typical X-ray diffraction (XRD) spectrum of the high-temperature, high-frequency piezoelectric ceramic compound proposed by the present invention. It can be seen from this th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com