Trace gasolene ingredient BTEX in ground water removal method with high-efficiency and low consumption

A groundwater and trace technology, applied in the field of water treatment, can solve the problems of large area of activated sludge pond, secondary pollution, increase of process operating costs, etc., to reduce construction sites and costs, reduce operating costs, and save processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

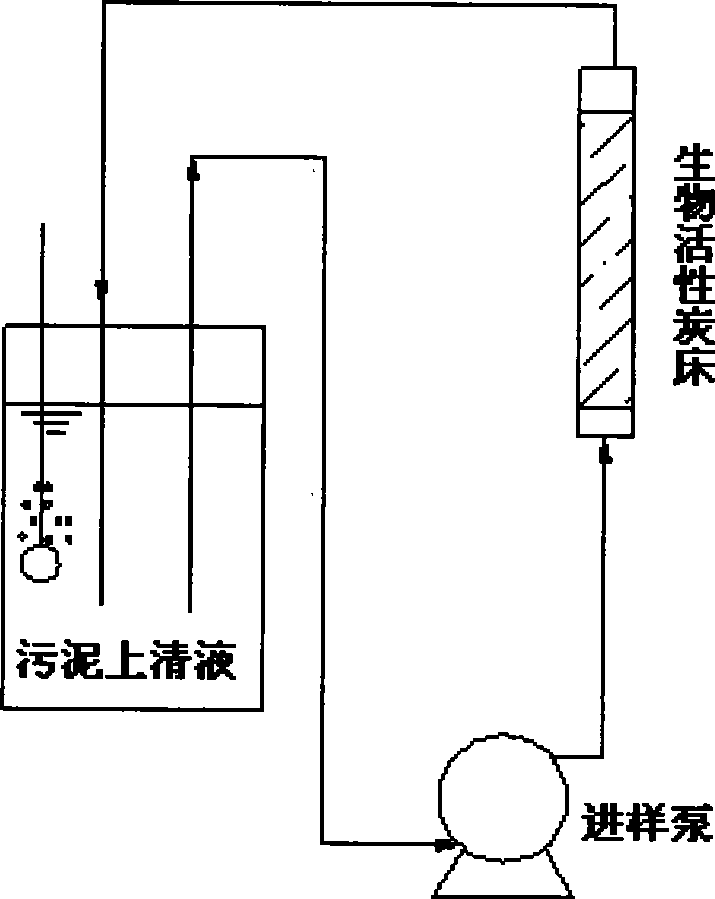

Embodiment 1

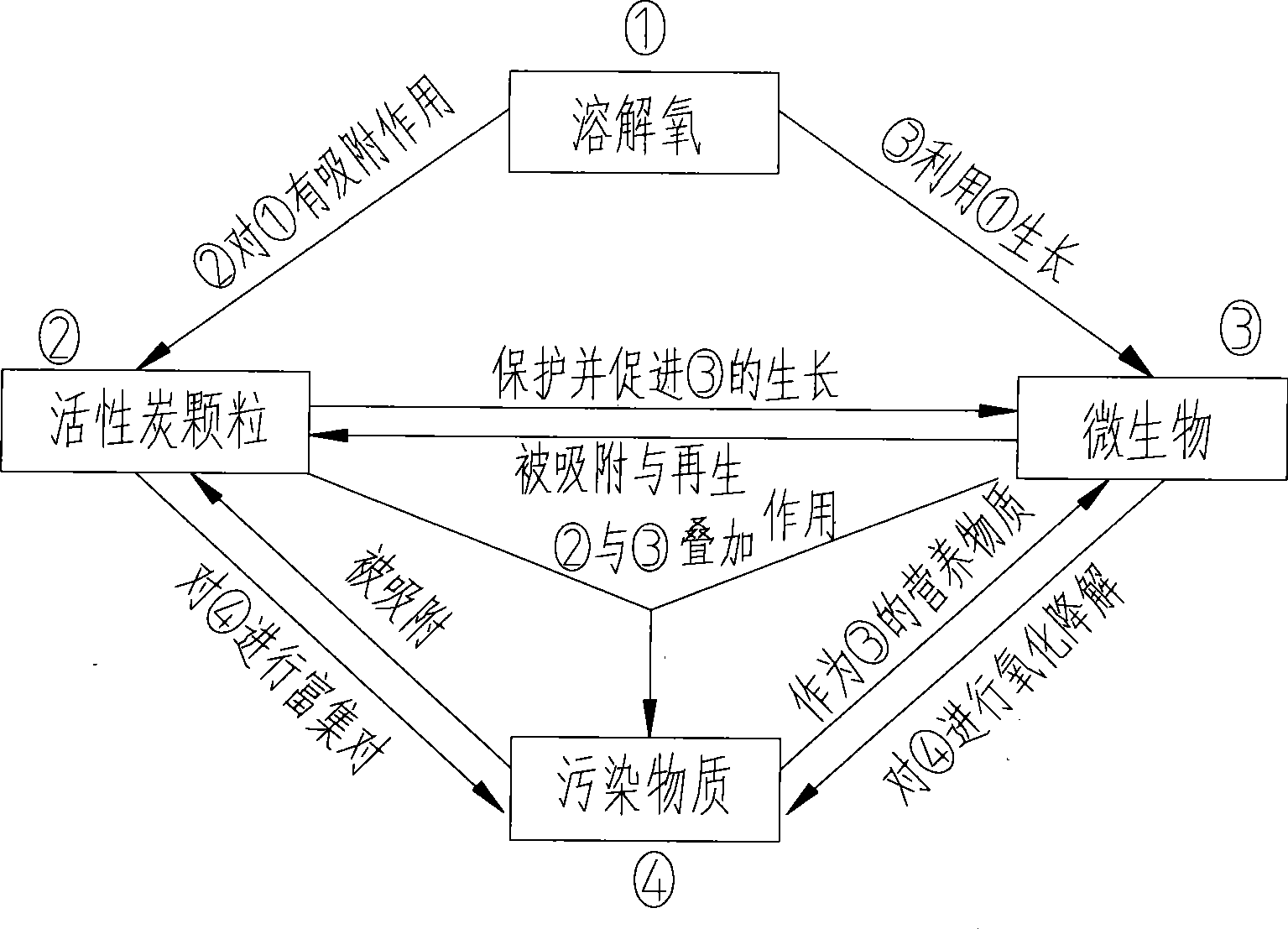

[0023] See figure 1 , 2 and 3, take raw coal crushed carbon (20-40 mesh) as the activated carbon carrier, use the bacteria domesticated in the toluene bio-activated carbon column in the early stage, set EBCT to 10min and inoculate for 2h. After that, EBCT was set to 1.2min, and the influent concentration was 30-50mg / L, and the biological activated carbon process of four benzene series (benzene, toluene, ethylbenzene and o-xylene) was carried out. After 2 weeks of treatment, it was shown that only The effluent concentration of benzene rises (to 10mg / L, C / C 0 was 0.29), then decreased slightly and remained at 5-10mg / L (C / C 0 is about 0.20), and the rest of the benzene series effluent has been maintained at a level of less than 5mg / L. The volume load of four sets of benzene series BAC is as high as 38.4~50.4kg / m 3 / d, after testing, the difference of dissolved oxygen in and out of the carbon column is maintained at 2.0-3.5 mg / L, which is much lower than the theoretical oxygen...

Embodiment 2

[0025] Take raw coal crushed charcoal (20-40 mesh) as the activated carbon carrier, use the bacteria domesticated in the toluene bio-activated carbon column in the early stage, set EBCT to 10min and inoculate for 2h. Set EBCT to 3.2min, with 10mg / L as the influent concentration, carry out the biological activated carbon process of four benzene series (benzene, toluene, ethylbenzene and o-xylene), after 40 days of treatment, in addition to benzene, No benzene series were detected in the BAC effluent of other BTEX. After the initial adsorption phase, the effluent concentration of benzene, which is poorly adsorbed and biodegradable, increased gradually (to 4 mg / L) and then slowly decreased below the detection limit (<0.5 mg / L). It shows that BAC can effectively remove BTEX in water for a long time.

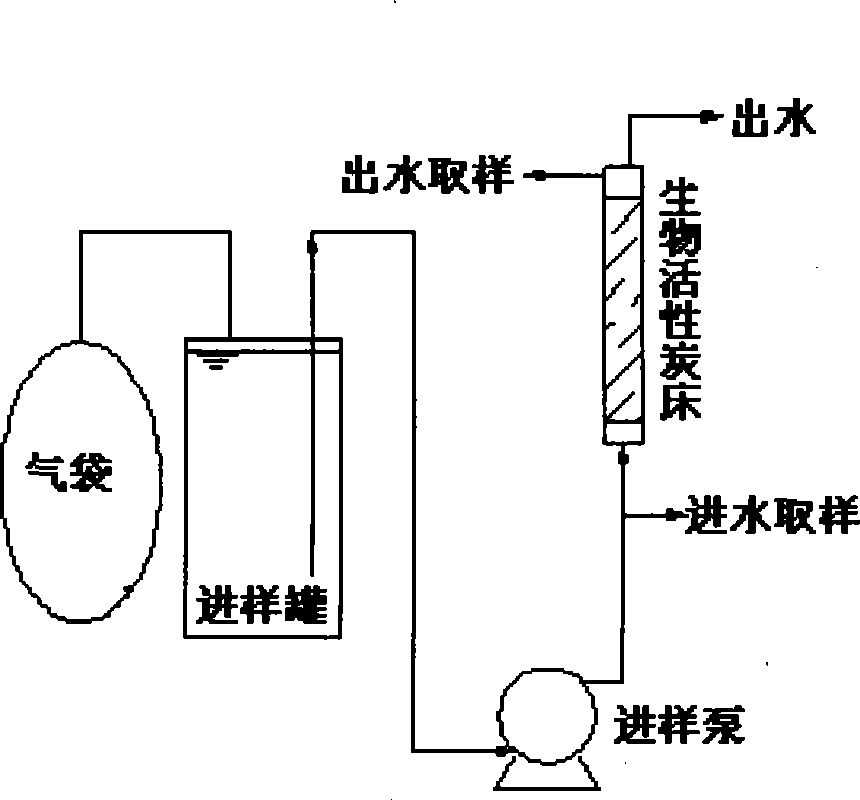

Embodiment 3

[0027] Raw coal crushed charcoal (20-40 mesh) and an equal volume of quartz sand were used as the carrier. The raw coal was preloaded with benzene, and the strains domesticated in the benzene bioactivated carbon column were used in the early stage. Set the EBCT to 1.1min, the influent concentration to 20-40mg / L, and carry out the biological activated carbon process of benzene. After three weeks of operation, it was shown that the benzene bioactivated carbon effluent C / C 0 It is kept at about 0.15-0.25, which is continuously lower than the effluent of quartz sand by 1-2 mg / L, indicating that activated carbon can provide a better growth environment for microorganisms and obtain a more ideal treatment effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com