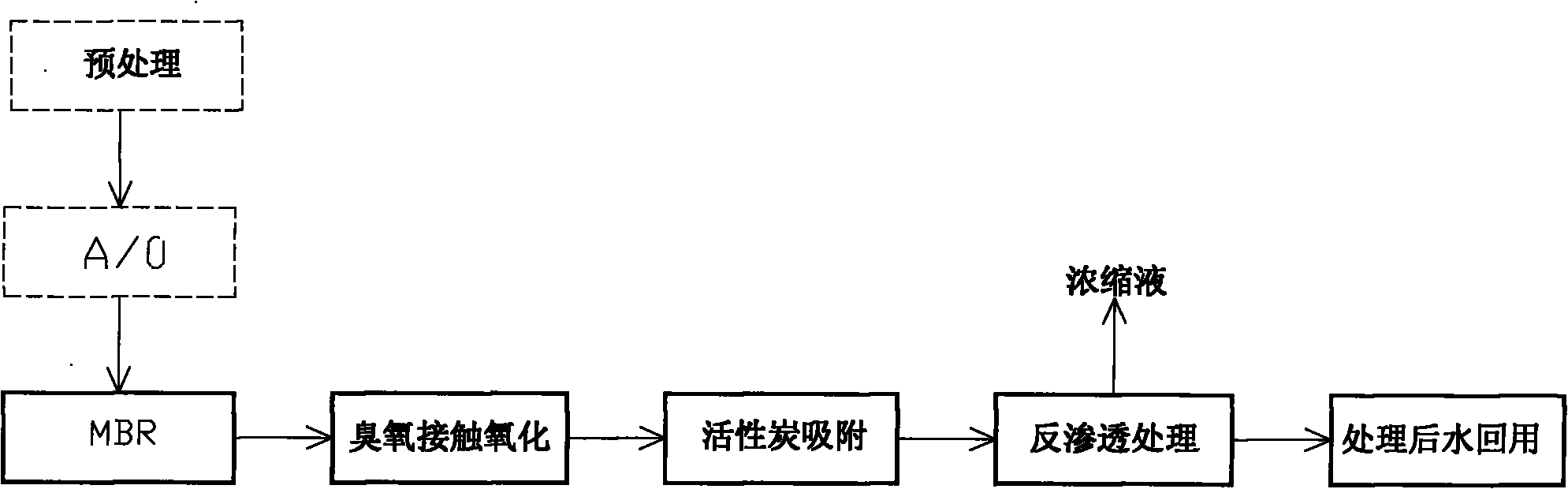

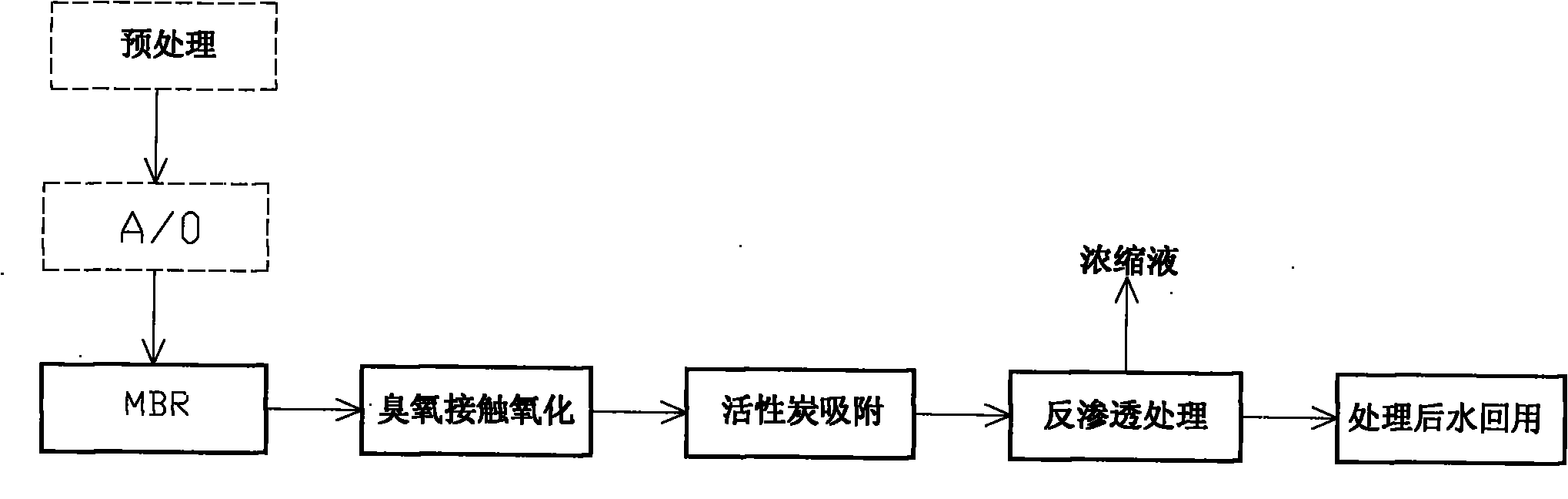

Advanced treatment process of coking waste water by combining ozone oxidation method and membrane separation technology

A coking wastewater and advanced treatment technology, applied in the direction of oxidation water/sewage treatment, aerobic and anaerobic process treatment, adsorption water/sewage treatment, etc., can solve high cost, failure to achieve the purpose of reuse, complex regeneration process, etc. problems, achieve the effects of saving land, realizing reuse, and increasing sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0052] Example 1: For a coking plant with an annual output of 1.5 million tons of coke, 76m of coking wastewater is produced 3 / h, circulating water sewage 52m 3 / h, the accumulative treated water volume is 128m 3 / h. The biochemical system adopts A / O internal circulation biological denitrification treatment technology, and the MBR water production is 128m 3 / h, water quality: CODCr≤120mg / L, NH 3 -N≤5mg / L, SS≤5mg / L, phenol≤0.5mg / L, cyanide≤0.5mg / L, meeting the national comprehensive discharge secondary standard. Then through pressurized pumping to the ozone contact oxidation tower and the O produced from the ozone generator 3 Fully contact to complete the oxidative decomposition treatment of pollutants such as COD that is difficult to biodegrade, and then remove unconsumed or excess ozone, partially soluble COD and a certain chromaticity through an activated carbon adsorption tower. After the activated carbon adsorption tower effluent is pressurized in series by the rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com