Synthetic recovering method for positive pole waste tablet from ferric phosphate lithium cell

A technology of lithium iron phosphate battery and recycling method, which is applied in battery recycling, waste collector recycling, electrode manufacturing and other directions, can solve the problems of inappropriate recycling of positive electrode material waste pieces, increasing cost pressure on battery manufacturers, and environmental pollution, etc. Achieve the effect of realizing economic benefits, environmental and social benefits, avoiding solid waste pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

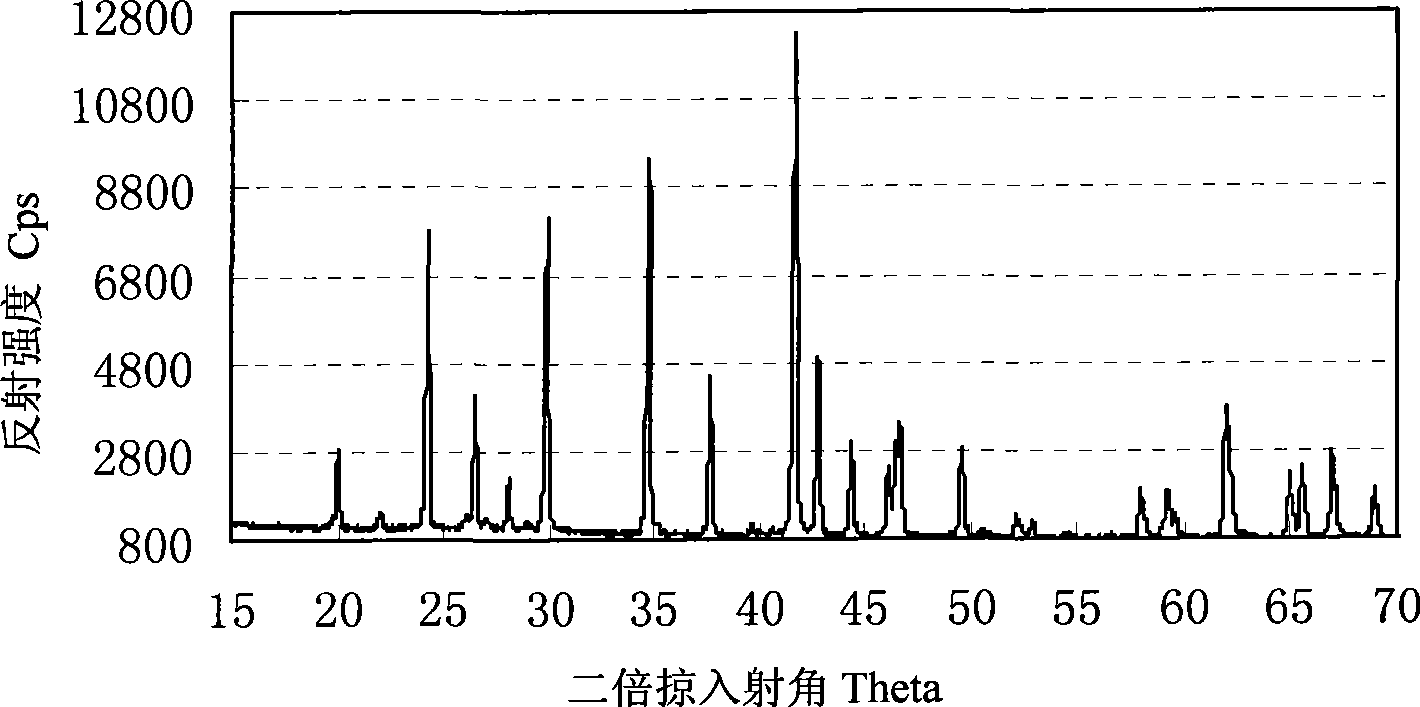

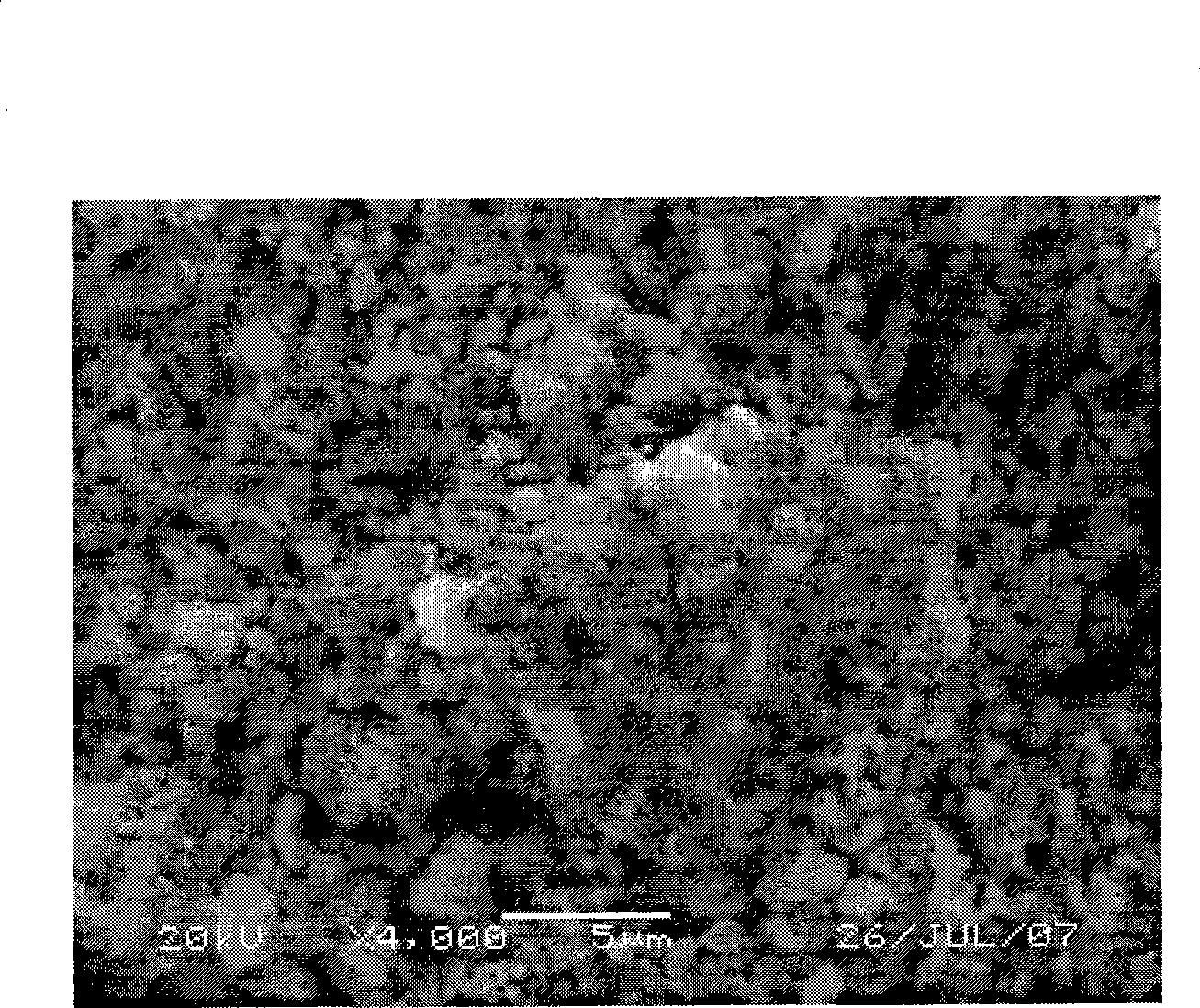

[0031] The positive electrode waste collected in the production of lithium iron phosphate batteries is crushed with a crusher, and the particle size of the crushed electrode pieces is controlled at 0.5-3cm. The broken positive electrode fragments were placed in a muffle furnace under nitrogen protection, and heat-treated at a temperature of 600° C. for 8 hrs to decompose the binder in the electrode piece. Use a vibrating sieve to sieve the heat-treated positive electrode waste. The undersieve is the mixture of lithium iron phosphate cathode material, conductive agent, and binder residue. The oversieve is aluminum foil, positive electrode material lumps and still The positive electrode material attached to the surface of the aluminum foil. The XRD pattern (X-ray diffraction pattern) and SEM pattern (scanning electron microscope pattern) of undersize image 3 and Figure 4 Shown, with the XRD pattern of lithium iron phosphate raw material ( figure 1 ) and SEM images ( figur...

Embodiment 2

[0034] The positive electrode waste collected in the production of lithium iron phosphate batteries is crushed with a crusher, and the particle size of the crushed electrode pieces is controlled at 4-8cm. The crushed positive electrode fragments were placed in a muffle furnace under nitrogen protection and heat-treated at a temperature of 400° C. for 6 hrs to invalidate the binder in the pole pieces. Vibrating sieves are used to sieve the heat-treated positive electrode waste. The undersieve is a mixture of lithium iron phosphate cathode material, conductive agent, and binder residue. The oversieve is aluminum foil, positive electrode material lumps and attached to Positive material on the surface of aluminum foil.

[0035] Soak the sieve obtained above in NMP at 45°C and keep stirring for 1 hour, the lithium iron phosphate positive electrode material, conductive agent and binder residues can be peeled off from the aluminum foil, and the separated aluminum foil is sent to the ...

Embodiment 3

[0037] The positive electrode waste collected in the production of lithium iron phosphate batteries is crushed with a crusher, and the particle size of the crushed electrode pieces is controlled at 4-8cm. The crushed cathode fragments were placed in a muffle furnace under nitrogen protection, and heat-treated at a temperature of 500° C. for 5 hrs to invalidate the binder in the pole pieces.

[0038]Soak the waste electrode piece after heat treatment in NMP at 60°C and keep stirring for 0.5h, the lithium iron phosphate cathode material, conductive agent and binder residue can be peeled off from the aluminum foil, and the separated aluminum foil is sent to the smelting plant for metal recovery aluminum. Continue stirring for 2 hrs to fully loosen and disperse the lumpy positive electrode mixture. Lithium iron phosphate positive electrode material, conductive agent and binder residues are filtered and baked at 120 for 20hrs. Use a mill to grind the dried mixture for 2hrs and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com