Novel coalbed gas thermal recovery process

A coalbed methane and new process technology, applied in the direction of mining fluid, earth cube drilling, wellbore/well parts, etc., can solve the problems of coal seam original structure damage, plastic enhancement, unsatisfactory effect, etc., to achieve clean mining, increase production, The effect of enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

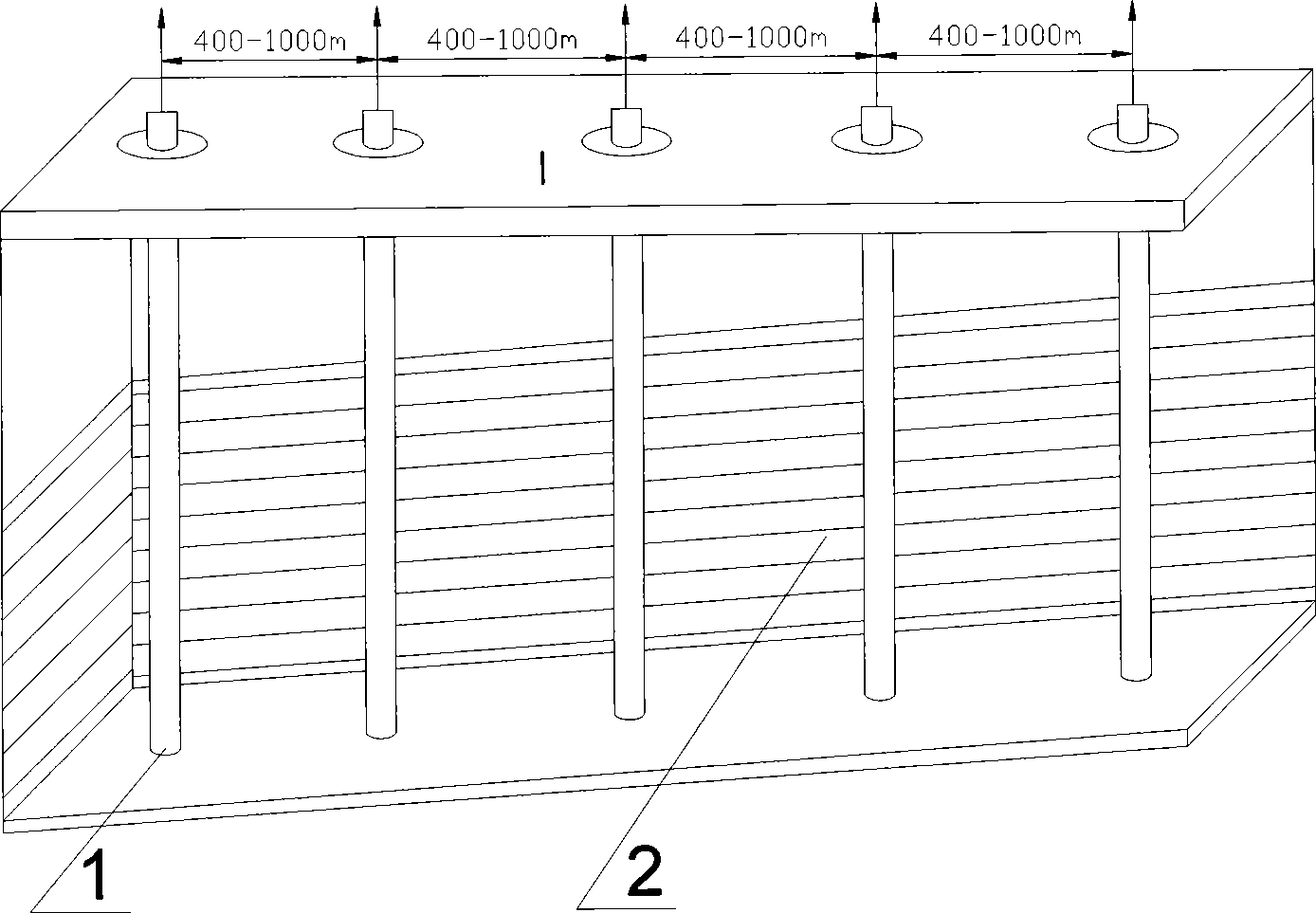

[0032] Single well heating coalbed methane drainage technology, such as figure 1As shown in a single well: in the coal seam, according to the geological structure of the coal seam, drill holes or use the original gas production well 1 to the bottom of the coal seam 2, put hot coke under the hole, and press in air or oxygen-enriched, so that The coke and the coal seam at the bottom of the hole are partially burned, and the heat generated by the combustion is transferred to the coal seam to heat the coal seam. When the coal seam is within the design range and reaches 100°C, stop supplying air or oxygen enrichment, and open the wellhead to discharge the exhaust gas cleanly. , according to the measurement of gas outlet gas composition, collect coalbed methane (mainly CH 4 ), which can significantly increase the single well CBM production. Another method is to reduce the amount of air or oxygen enrichment, so that the hot flue gas (mainly composed of CO) produced by combustion 2 ...

Embodiment 2

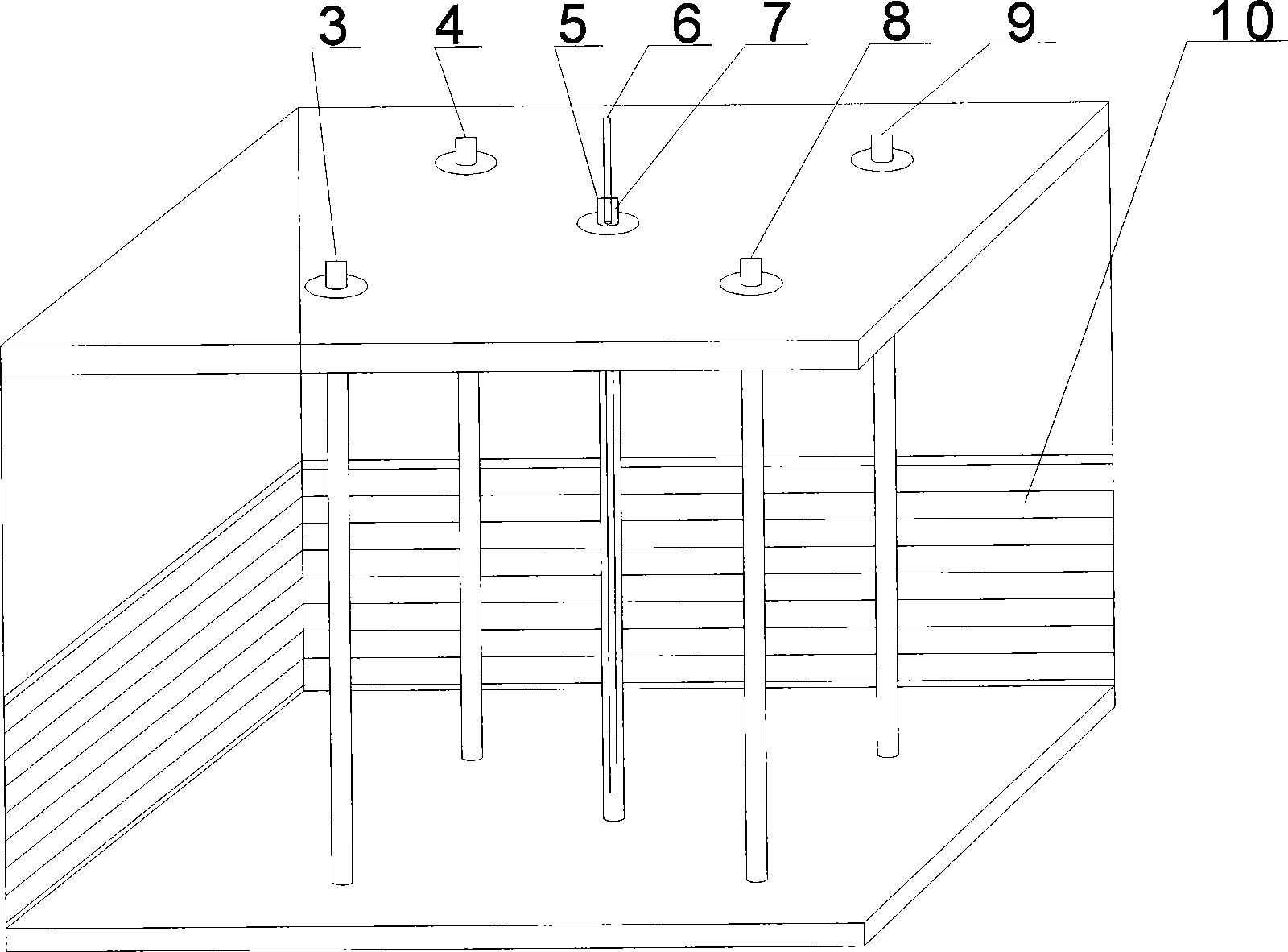

[0034] Vertical well group blind hole heating coalbed methane drainage process, drilling a vertical well 5 in the coal seam 10, see figure 2 , according to the well layout requirements of coalbed methane production and the expansion of the temperature field obtained from the test, four gas production wells (3, 4, 8, 9) are drilled at appropriate distances around the hole. After laying hot coke at the bottom of the hole 5, a gas supply pipe 6 is lowered, and gasification agent is supplied into the gas supply pipe 6, and the coal seam 10 is ignited with hot coke. The coal gas is discharged from the space 7 to realize the gasification of the blind holes to produce gas and heat the coal seam 10 at the same time. After coal seam 10 is heated, coalbed methane is collected in well 3, well 4, well 8 and well 9, and the output of coalbed methane will increase greatly.

Embodiment 3

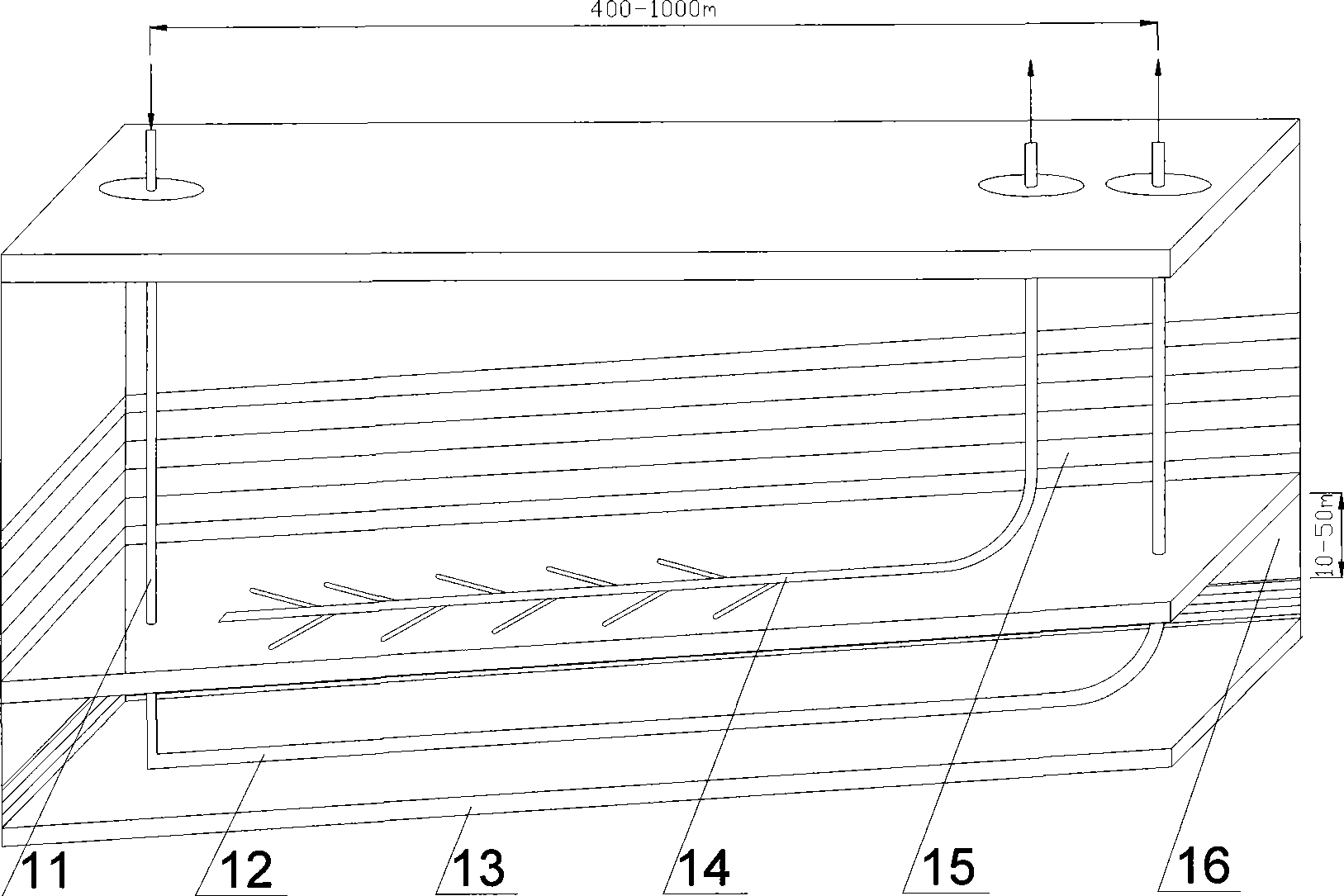

[0036] Horizontal directional well layered gasification heating coalbed methane mining technology, in two or more coal seams, if the distance 16 between the coal seams is within 50m, the upper layer and the upper layer can be heated by gasifying the lower (or middle) coal seam 13 Lower seam coal 15, such as image 3 shown. In the lower (or middle) coal seam 13, horizontal directional wells 12 are arranged, and vertical air intake wells 11 are constructed to form an underground combustion gasifier. The gasifier generally chooses a thinner coal seam and is lowered at the bottom of the vertical well 11. Coke, ignites the coal seam, and feeds the gasification agent. When the gasification agent is air, it can produce low calorific value gas. When blowing in oxygen-enriched or pure oxygen-water vapor, it can produce medium calorific value gas, which is discharged from the directional well 12. gas. Arrange coalbed methane production wells 14 in the upper (lower) coal seam 15 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com