Fluorescence labeling acrylic acid-sodium acrylic sulphonate co-polymer water treatment agent and preparation method thereof

A sodium propylene sulfonate, fluorescent labeling technology, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc., can solve the problems of limited development and application, rare and difficult reaction raw materials, etc. Achieve the effect of improving management level, simplifying on-site operation and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] Example 2 Add 120 g of water, 14.4 g of sodium propylene sulfonate, 2.5 g of sodium hypophosphite and the fluorescent monomer (FC) 0.4 g, heated to 80°C under stirring, then added dropwise 33g of 10% ammonium persulfate solution and 36g of acrylic acid, the temperature was controlled at 90°C, the dripping was completed within 10 minutes, the temperature was continued for 3-5 hours, and the product was cooled and discharged to obtain the product of the present invention FC-AA-SAS (yellow liquid), namely

[0044] Fluorescently labeled acrylic acid-propylene sulfonate sodium copolymer water treatment agent, the general formula of the polymer is:

[0045]

[0046] Wherein n and m are 1-20.

[0047] The polymer has multiple functions such as fluorescent tracer function, scale inhibition and dispersion.

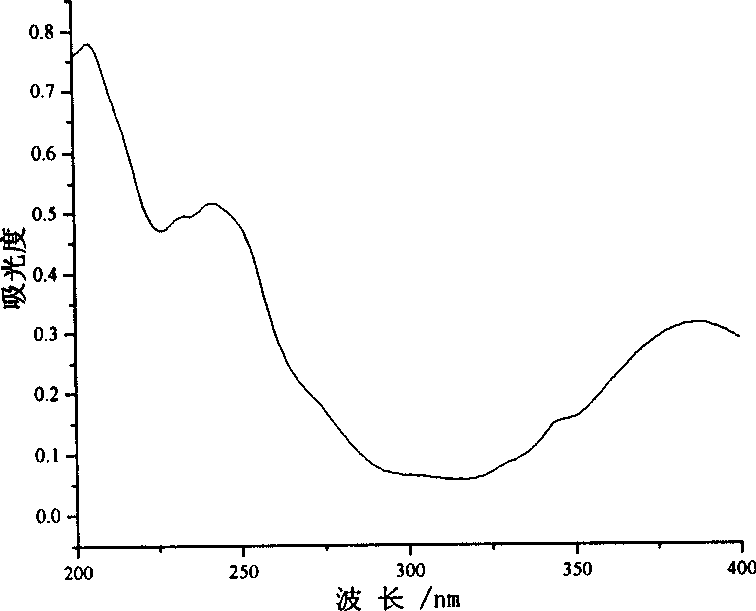

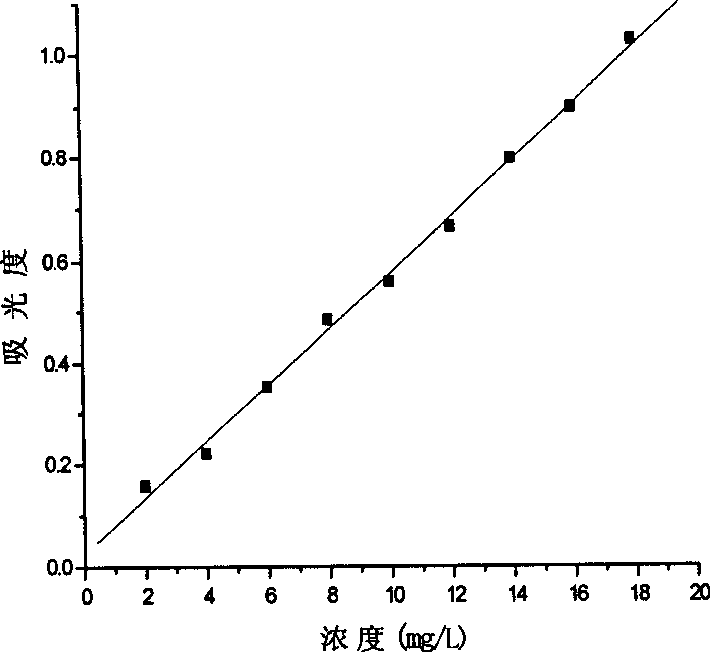

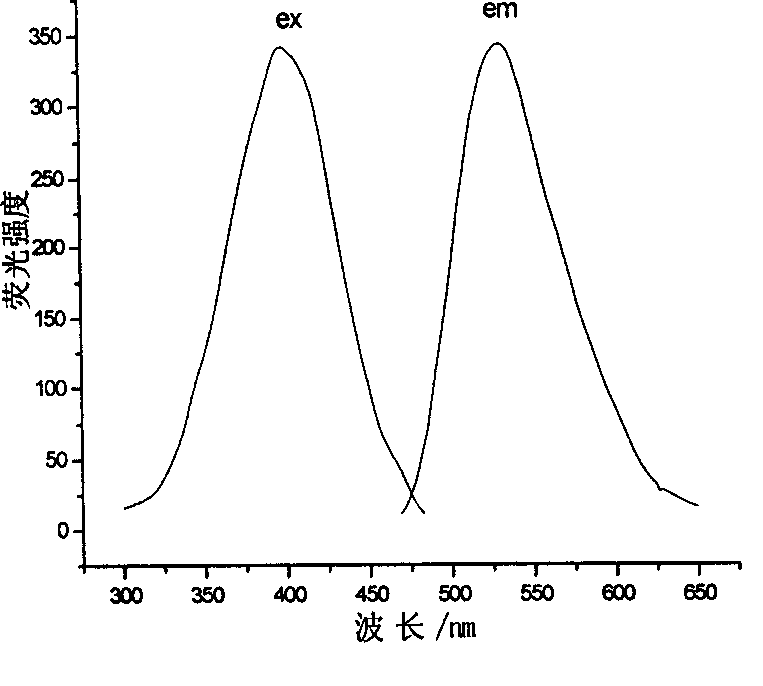

[0048] The ultraviolet absorption spectrum of the polymer is similar to that of the fluorescent monomer, and has absorption at 233nm and 388nm respectively. Its excita...

Embodiment 3

[0050] Example 3 The static scale inhibition method was used to evaluate the scale inhibition performance of FC-AA-SAS in Example 2 on calcium phosphate. The test conditions are as follows: temperature: 80°C; medicament: the product of Example 2; dosing concentration: 25mg·L -1 ;Test time: 10h; Test configuration water: Ca 2+ 250mg·L -1 , HCO 3 - 250mg·L -1 (both CaCO 3 count), PO 4 3- 5mg·L -1 , and the pH value is 9.0; at the same time, do a blank experiment without adding any medicament.

[0051] According to this method, the scale inhibition rate of the agent to calcium phosphate reaches 86.5%.

Embodiment 4

[0052] Example 4 The static scale inhibition method was used to evaluate the scale inhibition performance of FC-AA-SAS in Example 2 on calcium sulfate. The test conditions are as follows: temperature: 80°C; medicament: the product of Example 2; dosing concentration: 15mg·L -1 ;Test time: 10h; Test configuration water: Ca 2+ 2940mg·L -1 (as CaCO 3 Count), SO 4 2- 7200mg·L -1 , and the pH value is 7.5; at the same time, do a blank experiment without adding medicine.

[0053] According to this method, the scale inhibition rate of the agent to calcium sulfate is 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com