Novel tubular hard surfacing material

A surfacing material and hard surface technology, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of the mismatch between the strength and toughness of the base metal, and achieve improved surfacing welding processability, optimized strength, Apply promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The tubular welding rod filler powder is composed of: 75% spherical cemented carbide particles with a particle size of 14-40 mesh; 15% surface-treated cast tungsten carbide particles with a particle size of 40-100 mesh; 5% spherical cast tungsten carbide particles Granules, with a particle size of 80-325 mesh; 2.8% of 200-mesh SiMn powder; 0.2% of 200-mesh phenolic resin powder; 2% of 200-mesh Nb alloy powder. The tube skin is low carbon steel H08A, the tube diameter is 4mm, and the tube skin thickness is 0.4mm. The filler powder accounts for 60% of the weight of the electrode.

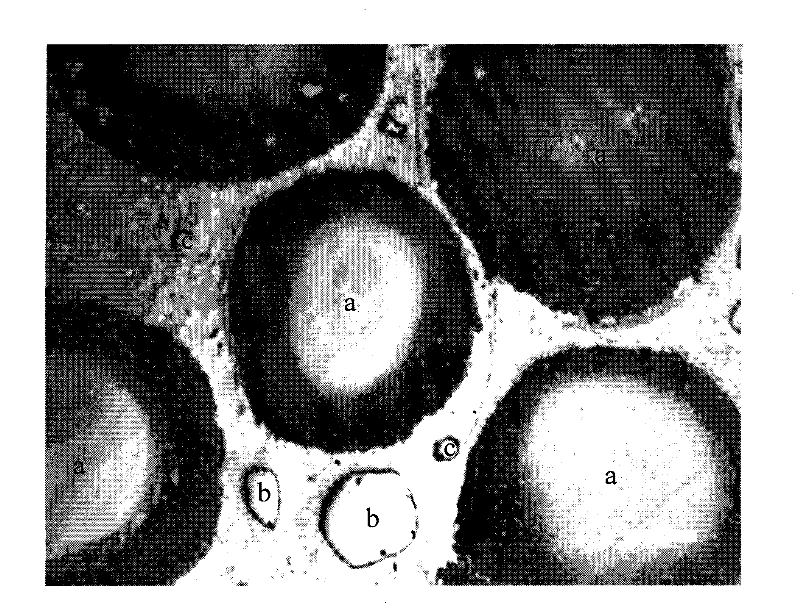

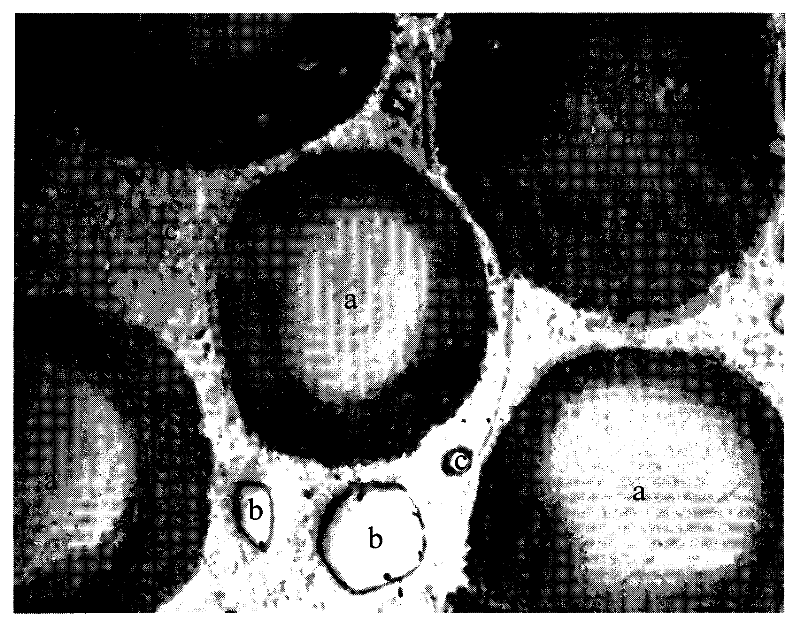

[0033] After surfacing, the metallographic phase of the surfacing layer is as follows: figure 1 shown. In this embodiment, the apparent dimension hardness of spherical cemented carbide particles in the surfacing layer is: HV 0.1 1366, the surface treated cast tungsten carbide particles have a microhardness of: HV 0.1 2993, the microhardness of spherical cast tungsten carbide particles is:...

Embodiment 2

[0035] The tubular welding rod filler powder is composed of 60% spherical cemented carbide particles with a particle size of 14-40 mesh; 17.3% surface-treated cast tungsten carbide particles with a particle size of 40-100 mesh; 20% spherical cast tungsten carbide particles Particles, the particle size is 80-325 mesh; 2% 200 mesh SiMn powder; 0.6% 200 mesh phenolic resin powder; 0.1% 200 mesh Nb alloy powder. The tube skin is low carbon steel H08A, the tube diameter is 4mm, and the tube skin thickness is 0.2mm. The filler powder accounts for 80% of the weight of the electrode.

[0036] In this embodiment, the apparent dimension hardness of spherical cemented carbide particles in the surfacing layer is: HV 0.1 1341, the surface treated cast tungsten carbide particles have a microhardness of: HV 0.1 2971, the microhardness of spherical cast tungsten carbide particles is: HV 0.13080, the microhardness of the base metal is: HV 0.05 786, metal wet sand wear test shows that th...

Embodiment 3

[0038] The tubular welding rod filler powder is composed of 55% spherical sintered carbide particles with a particle size of 14-40 mesh; 25% surface-treated tungsten carbide particles with a particle size of 40-100 mesh; 13% spherical cast tungsten carbide Particles, the particle size is 80-325 mesh; 6% 200 mesh SiMn powder; 0.4% 200 mesh phenolic resin powder; 0.6% 200 mesh Nb alloy powder. The tube skin is low carbon steel H08A, the tube diameter is 4mm, and the tube skin thickness is 0.3mm. The filler powder accounts for 70% of the weight of the electrode.

[0039] In this embodiment, the apparent dimension hardness of spherical cemented carbide particles in the surfacing layer is: HV 0.1 1368, the surface treated cast tungsten carbide particles have a microhardness of: HV 0.1 2897, the microhardness of spherical cast tungsten carbide particles is: HV 0.1 3015, the microhardness of the base metal is: HV 0.05 807, metal wet sand wear test shows that the wear resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com