Photocurable composition for the formation of pressure-sensitive adhesive layer and dicing tape produced using the same

A technology of pressure-sensitive adhesives and cutting tapes, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of outdated and improved absolute peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0077] Preparation Example 1: Preparation of Pressure Sensitive Adhesive (PSA) Adhesive

[0078] 6.00 kg of methyl ethyl ketone and 0.60 kg of toluene were used as organic solvents and put into a 20 L four-necked flask equipped with a reflux condenser, a thermometer and a dropping funnel. The temperature of the flask was raised to 60°C. Then, 3.40 kg of 2-ethylhexyl acrylate, 0.20 kg of ethyl acrylate, 0.30 kg of vinyl acetate, 0.48 kg of 2-hydroxyethyl methacrylate, 0.43 kg of acrylic acid and 0.04 kg of peroxide Benzoyl was mixed together and added dropwise to the flask at 60-70°C through the dropping funnel over 3 hours while stirring at 250 rpm. After the addition was complete, the reaction mixture was aged for 4 hours under the same conditions, and then 0.20 kg of ethyl acetate and 0.01 kg of azobisisobutyronitrile were added thereto. The resulting mixture was left for 4 hours and the viscosity and solids content were measured. The reaction was stopped to obtain an acr...

Embodiment 1

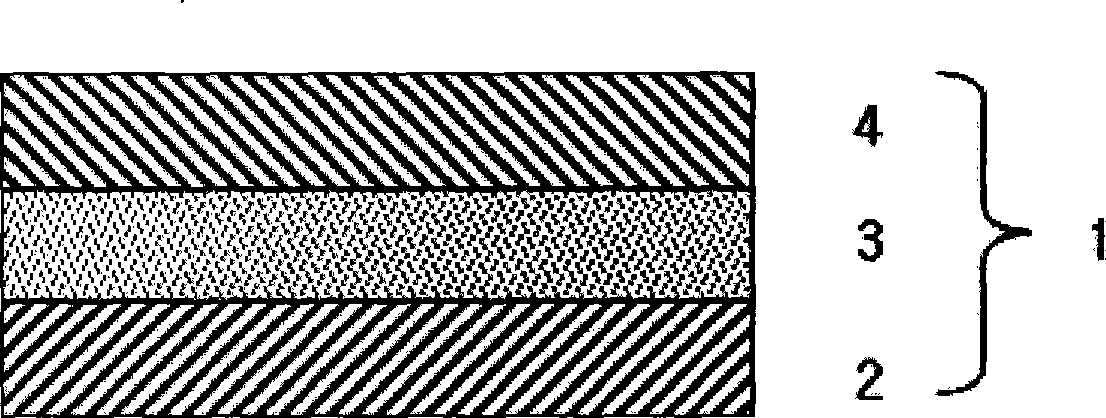

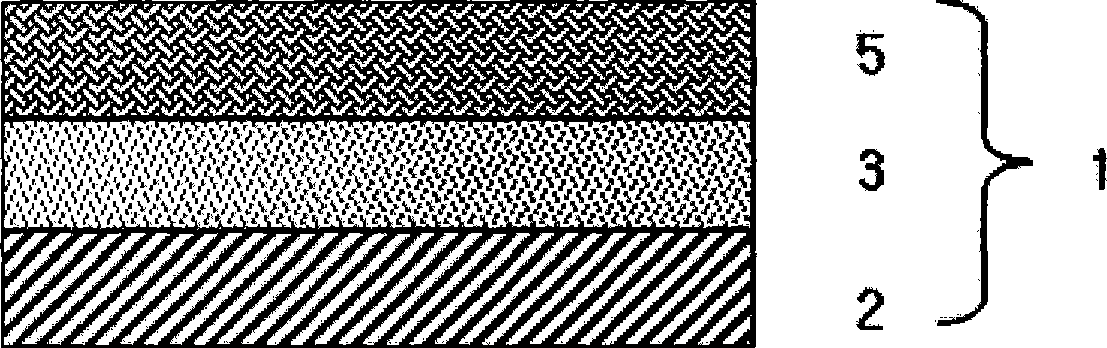

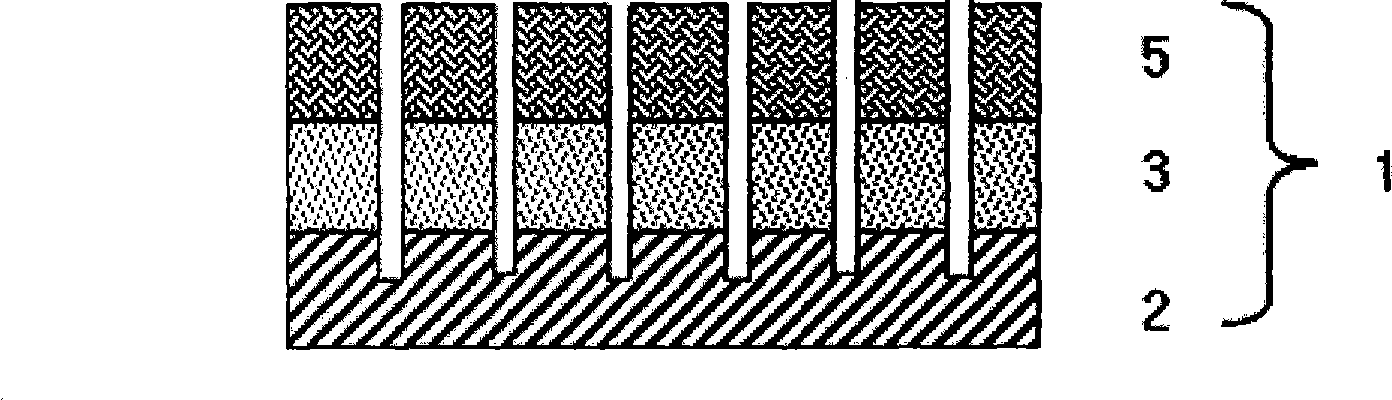

[0080] 100 g of PSA adhesive (A), 1 g of reactive acrylate (X-22-164B, Shin-Etsu Chemical Co., Ltd.) with a weight average molecular weight of 1,630 g / mol, 1 g of isocyanate curing agent (L -45, Nippon Polyurethane Industry Co., Ltd.) and 0.5 g of photoinitiator (IC-184, Ciba-Geigy) were mixed together to prepare a UV-curable pressure-sensitive adhesive (PSA) composition. This photocurable composition was coated on one surface of a 100 μm thick polyolefin film, and dried to prepare a 10 μm thick dicing tape (a).

Embodiment 2

[0082] 100 g of PSA adhesive (A), 1 g of reactive acrylate (X-22-164C, Shin-Etsu Chemical Co., Ltd.) with a weight average molecular weight of 2,730 g / mol, 1 g of isocyanate curing agent (L -45, Nippon Polyurethane Industry Co., Ltd.) and 0.5 g of photoinitiator (IC-184, Ciba-Geigy) were mixed together to prepare a UV-curable PSA composition. The photocurable composition was coated on one surface of a 100 μm thick polyolefin film and dried to prepare a 10 μm thick dicing tape (b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com