Combined processing machine for returning straw to field and crushing root stubble

A technology of combining working machine and stubble, applied in the field of agricultural machinery, can solve the problems of easy damage of cutting tools, affecting the working speed of machinery and tools, increasing power consumption of tractors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

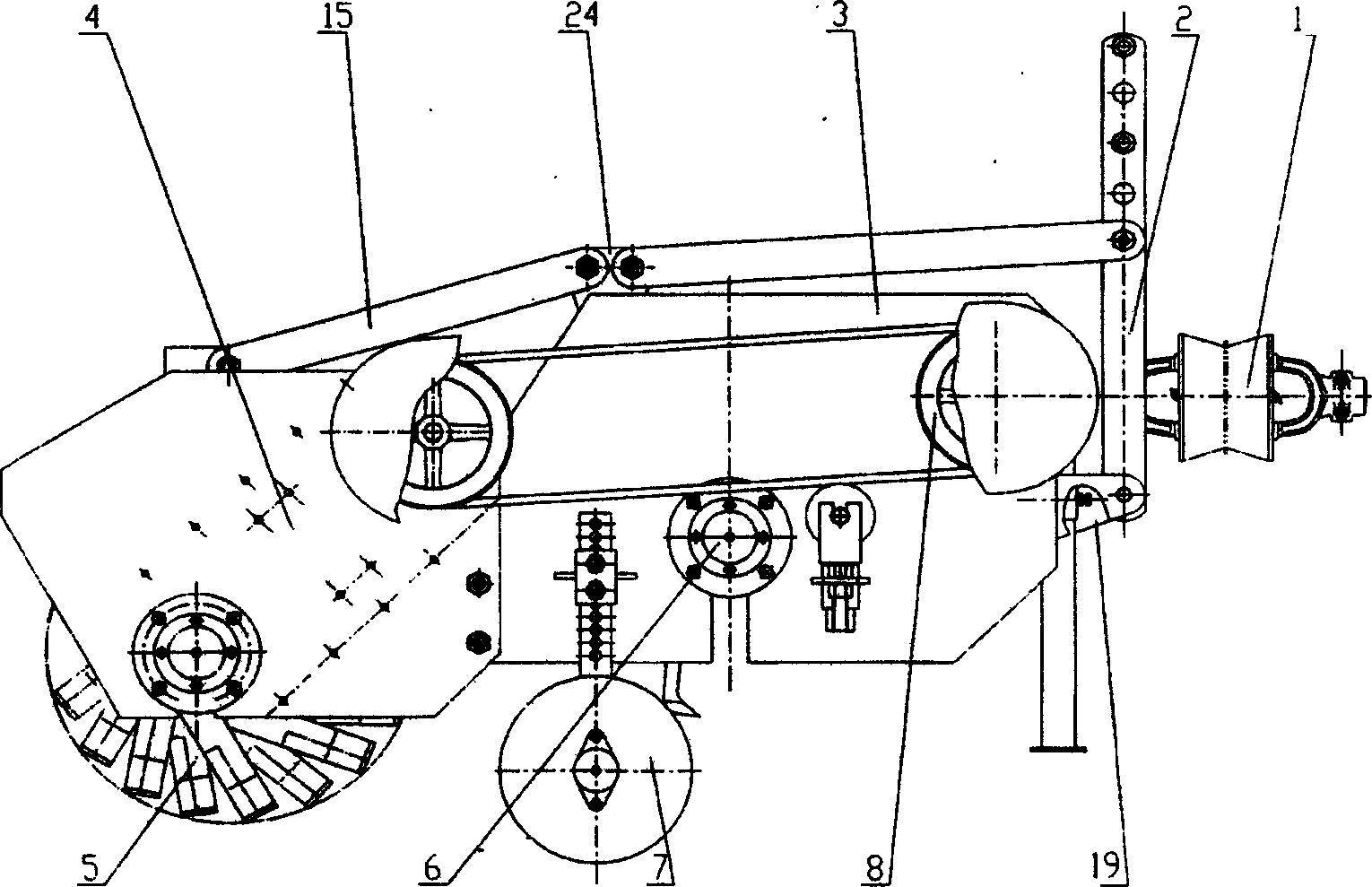

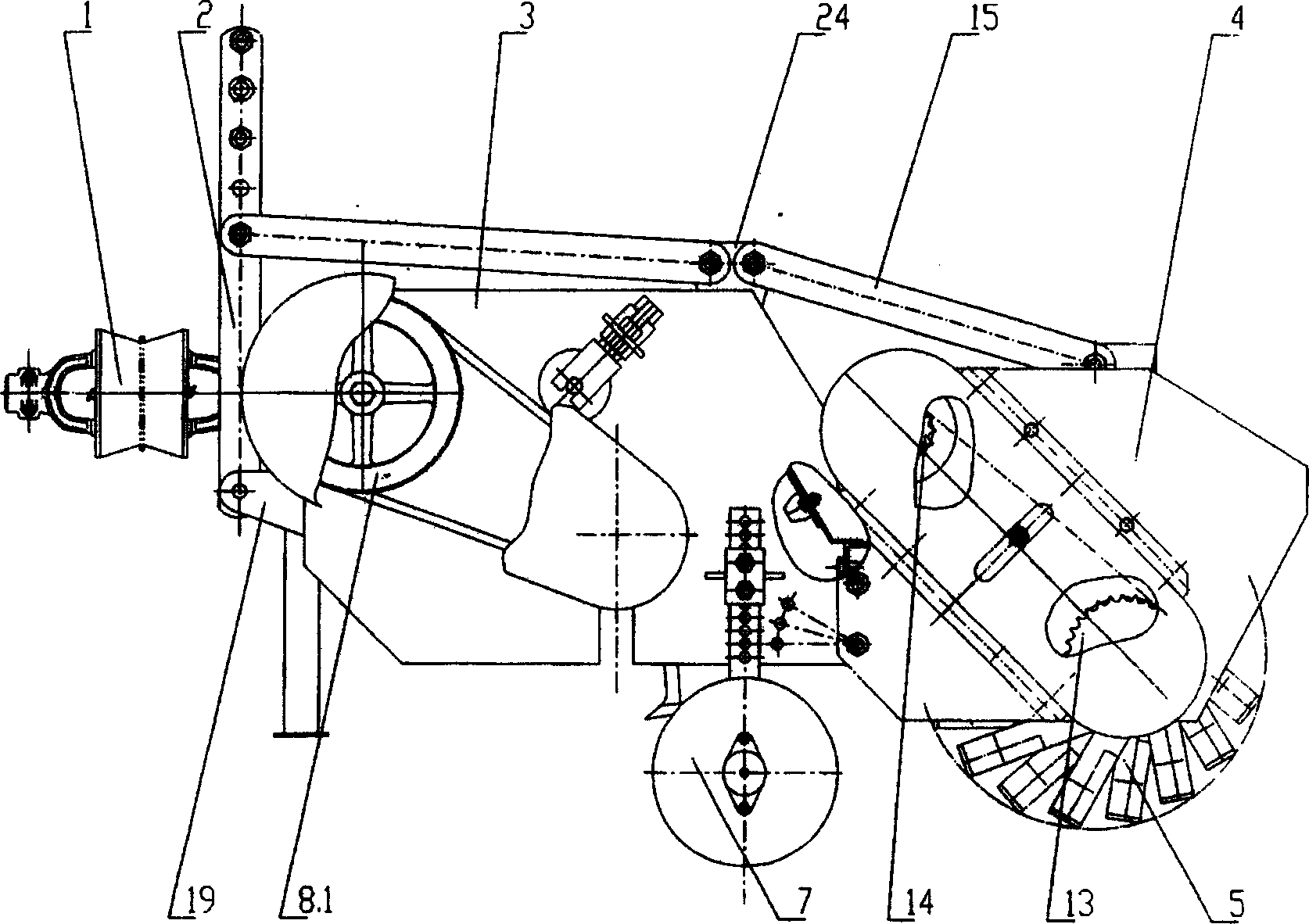

[0021] The structure of the present invention is described in further detail in the following embodiments given in conjunction with the accompanying drawings.

[0022] refer to Figures 1 to 3 , straw returning and root stubble crushing combined operation machine, including field returning knife roller 6 and stubble crushing knife roller 5 driven by tractor power, characterized in that the frame of the whole machine consists of field returning frame 3 and stubble crushing frame 4 Composed of front and rear fastening connections, the field returning knife roller 6 arranged on the field returning frame 3 and the stubble crushing knife roller 5 arranged on the stubble crushing frame 4 are respectively connected with the gearbox 10 arranged on the field returning frame 3 The left output shaft 33 and the right output shaft 38 are drivingly connected, the input shaft 37 of the gearbox 10 is drivingly connected with the tractor power output shaft through the universal joint 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com