Method for preparing visible light responding TiO2 mixed crystal using bergmeal as substrate

A diatomite and visible light technology, applied in the fields of photocatalysis and material chemistry, can solve the problems of easy coagulation, difficult separation and recovery of suspension systems, and no application in production practice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

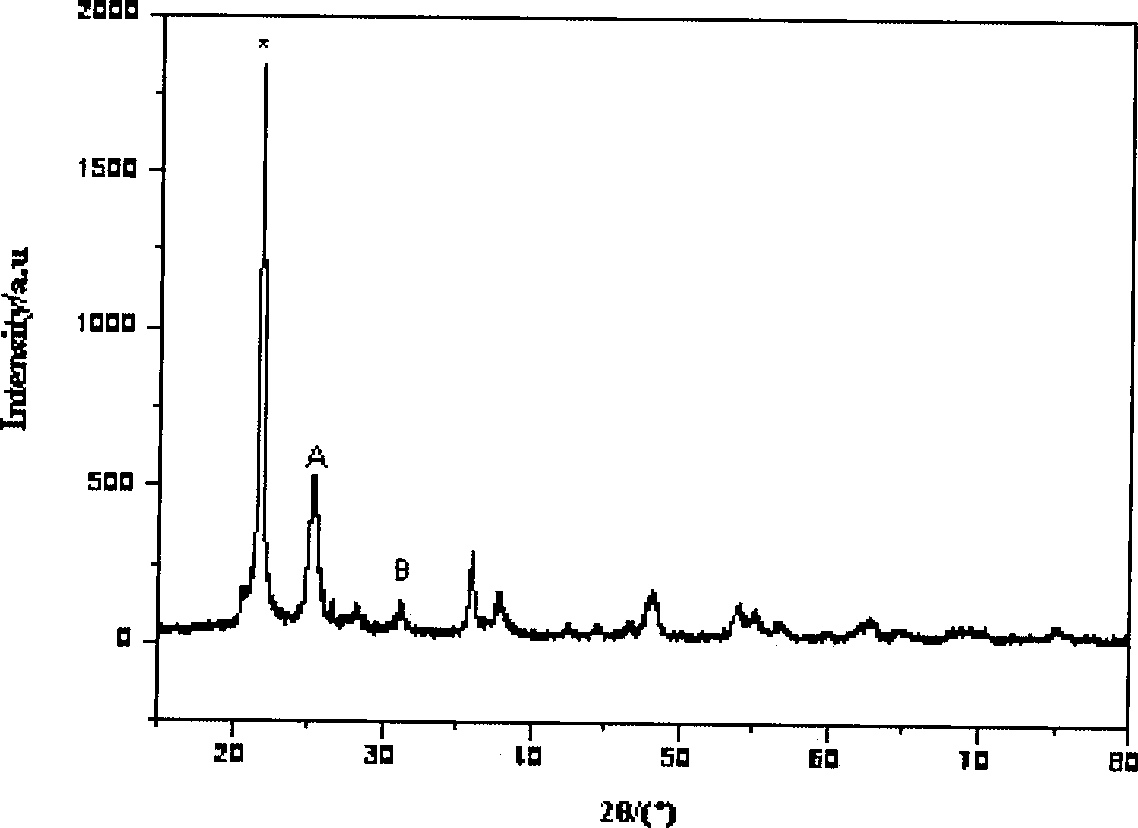

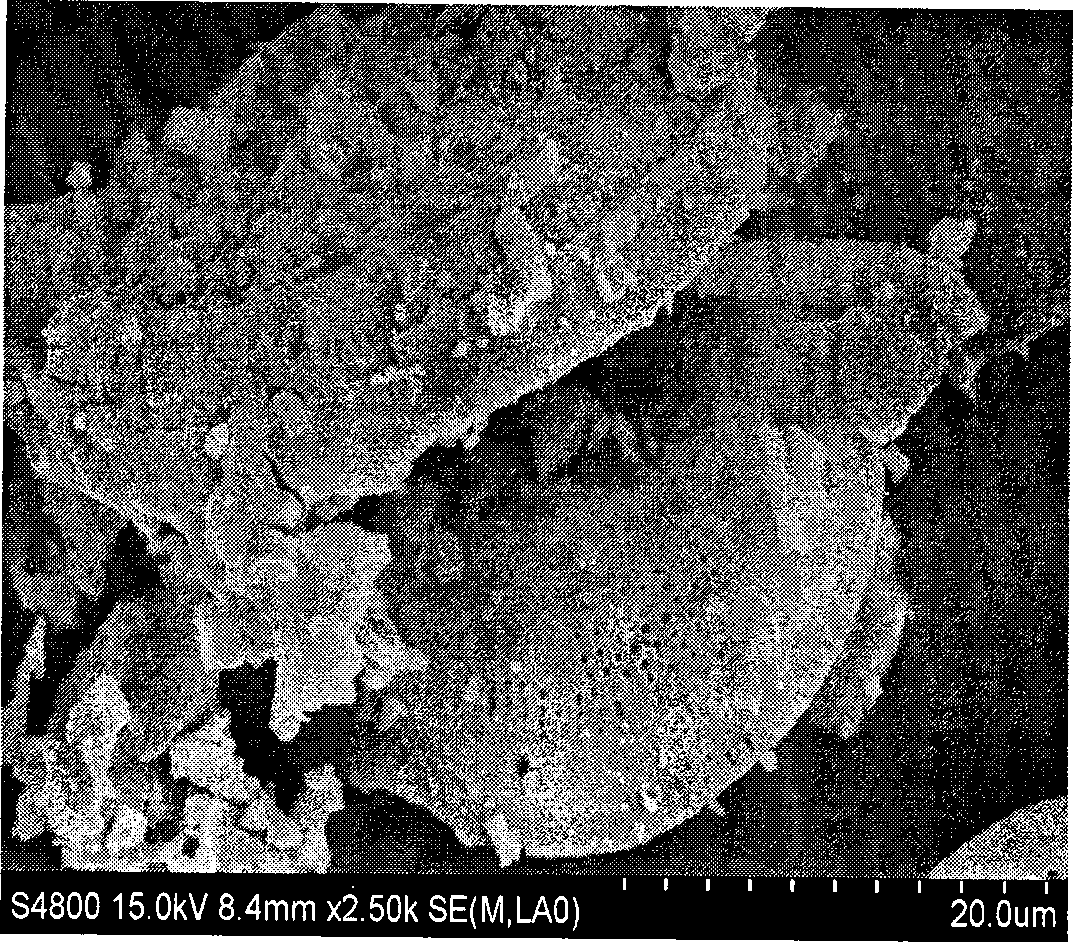

Image

Examples

Embodiment 1

[0019] 1. Slowly add 10ml of titanium tetrachloride dropwise into the ice bath, control the drop rate to 40 drops / min, stir at a speed of 2000 rpm for 2 hours after all the drops are completed, adjust the pH value at 7.0 with ammonia water, and obtain White precipitate, continue to stir for 3 hours, filter and wash the precipitate until there is no chloride ion, dissolve it in water, add 10ml of hydrogen peroxide, stir for 2 hours, add 0.1g of sodium phosphate and 0.1g of carboxymethyl cellulose It is placed in a reaction kettle at 100°C for 6 hours, and then taken out for later use.

[0020] 2. Diatomaceous earth is activated at 450°C for 2 hours, then poured into 5% dilute hydrochloric acid and stirred for 5 hours, then taken out and dried.

[0021] 3. Mix and stir the prepared titanium dioxide and activated diatomaceous earth, dry and bake at 550° C. for 5 hours to obtain the target diatomite-based mixed crystal titanium dioxide powder with visible light activity.

Embodiment 2

[0023] 1. Slowly add 10ml of titanium tetrachloride dropwise into an ice bath, control the drop rate to 20 drops / min, stir at a speed of 2000 rpm for 3 hours after all the drops are completed, adjust the pH value at 5.0 with ammonia water, and obtain White precipitate, continue to stir for 3 hours, filter and wash the precipitate to no chloride ion, dissolve in water, add 20ml of hydrogen peroxide, stir for 2 hours, add 0.05g of sodium phosphate and 0.05g of carboxymethyl cellulose It is placed in a reaction kettle at 150°C for 4 hours, and then taken out for later use.

[0024] 2. Diatomaceous earth is activated at 600°C for 5 hours, then poured into 1% dilute hydrochloric acid and stirred for 10 hours, then taken out and dried.

[0025] 3. Mix and stir the prepared titanium dioxide and activated diatomaceous earth, dry and bake at 450° C. for 8 hours to obtain the target diatomite-based mixed crystal titanium dioxide powder with visible light activity.

Embodiment 3

[0027] 1. Slowly add 10ml of titanium tetrachloride dropwise into an ice bath, control the drop rate at 50 drops / min, stir at a speed of 2000 rpm for 5 hours after all the drops are completed, adjust its pH value at 9.0 with ammonia water, and obtain White precipitate, continue to stir for 3 hours, filter, wash the precipitate to no chloride ion, add 15ml of hydrogen peroxide to it after dissolving in water, stir for 2 hours, add 0.02g of sodium phosphate and 0.02g of carboxymethyl cellulose It is placed in a reaction kettle at 80°C for 12 hours, and then taken out for later use.

[0028] 2. Diatomite is activated at 800°C for 1 hour, then poured into 10% dilute hydrochloric acid and stirred for 2 hours, then taken out and dried.

[0029] 3. Mix and stir the prepared titanium dioxide and activated diatomaceous earth, dry and bake at 600° C. for 2 hours to obtain the target diatomite-based mixed crystal titanium dioxide powder with visible light activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com