Disinfectant liquid and method for producing the same

A disinfectant and component technology, applied in the direction of disinfectant, botany equipment and method, biocide, etc., can solve the problems of short duration of disinfection, high investment in equipment, inability to get rid of the defects of peroxide application, etc., and achieve good Economic and environmental benefits, safe and convenient transportation and storage, good promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

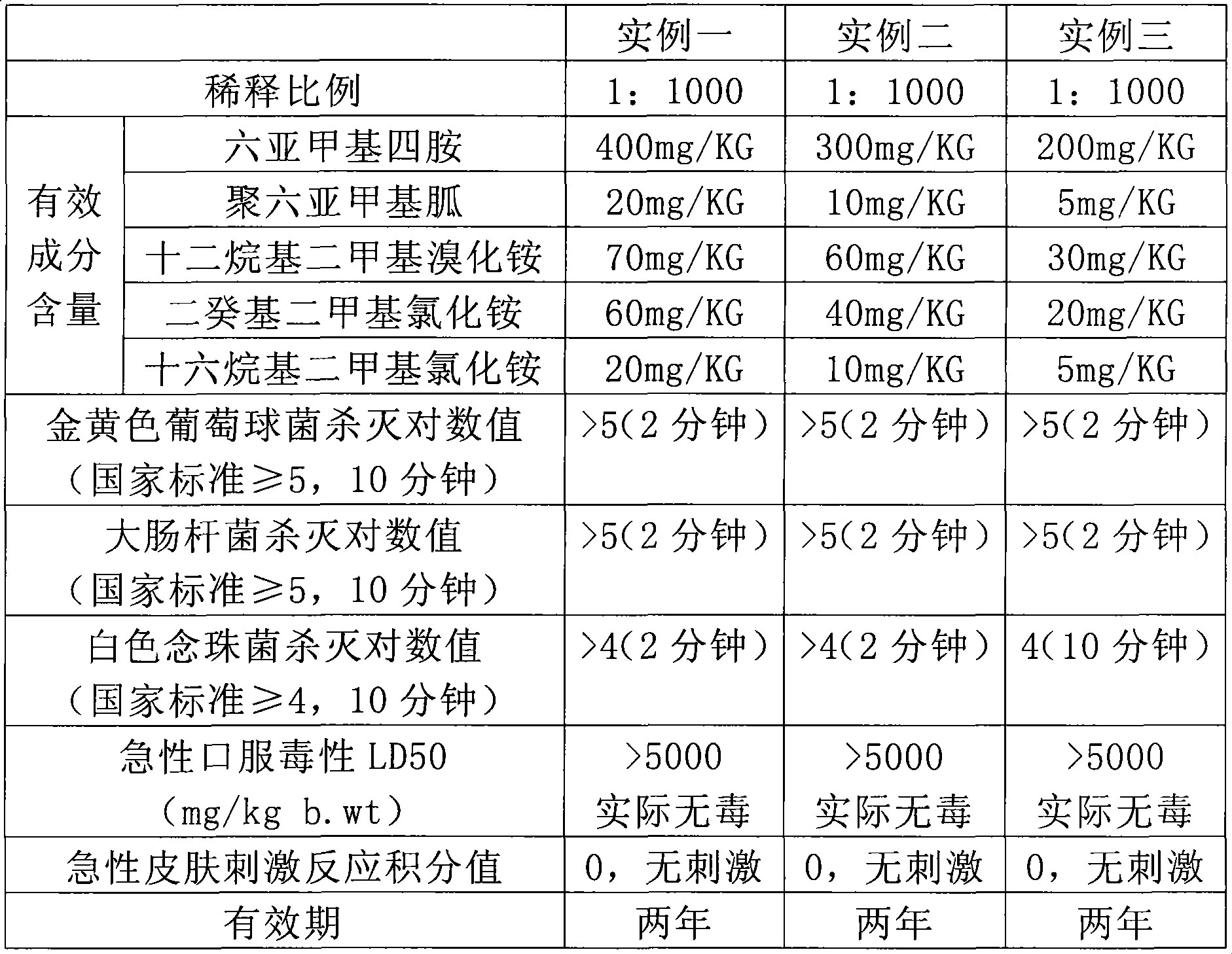

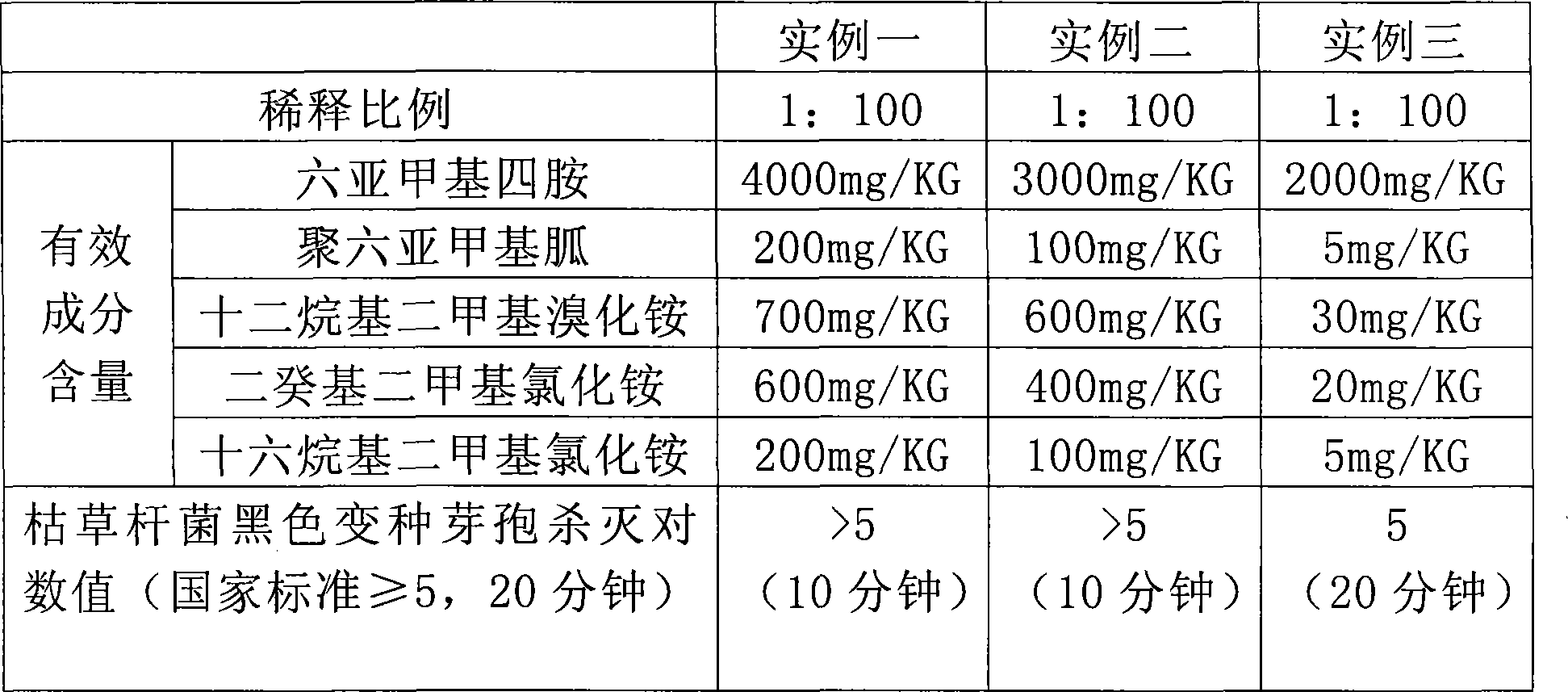

Embodiment 1

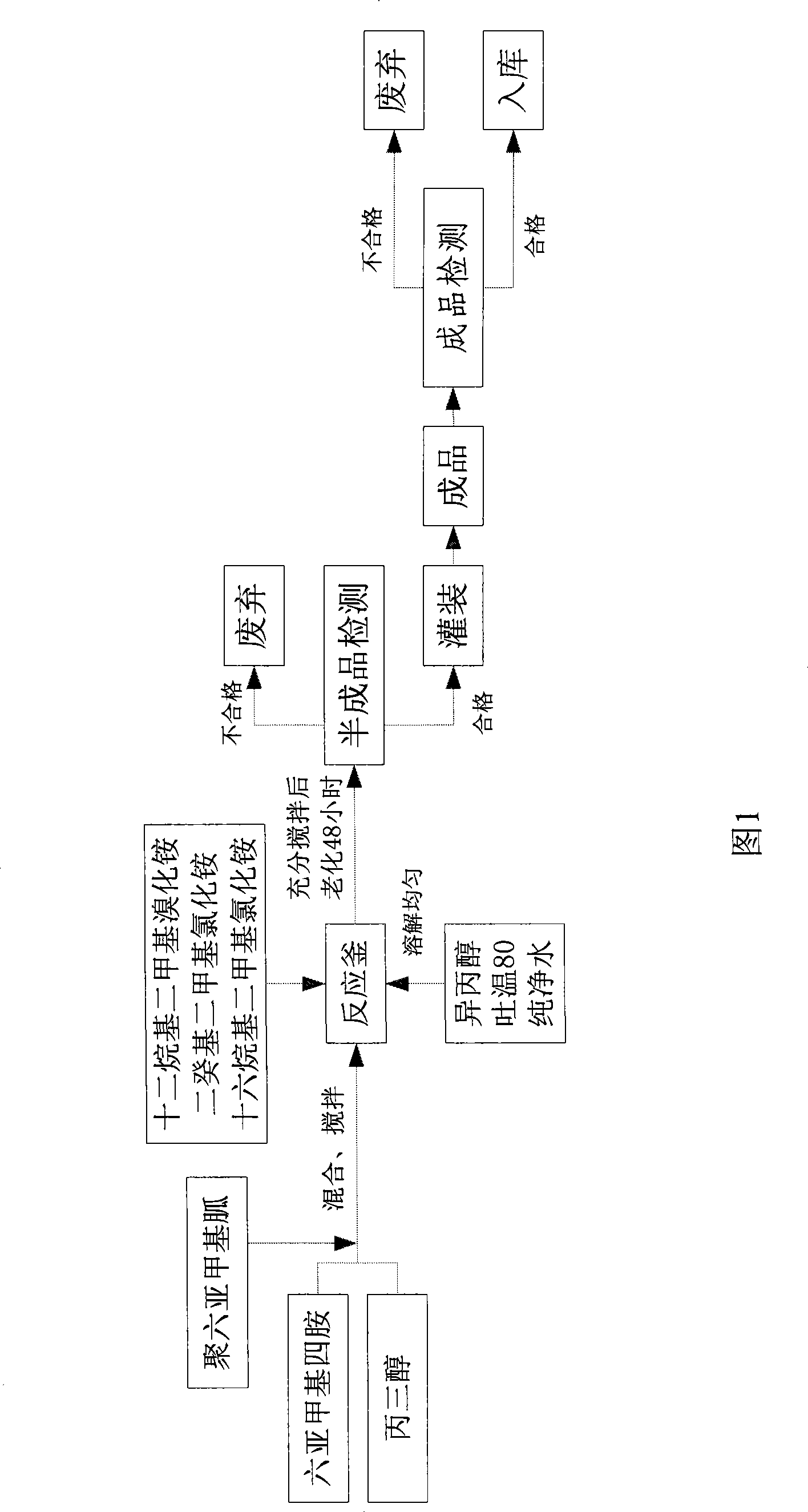

[0026] A kind of production method of disinfectant of the present invention adopts following processing steps:

[0027] 1. Join 2 kilograms of glycerol (trade name: glycerin, purity: 99%) to 40 kilograms of hexamethylenetetramine (trade name: urotropine, purity: 99%), then add 2 kilograms of poly Hexamethylene guanidine (purity: 99%) was mixed and stirred for 2 hours under the conditions of normal temperature 30°C and normal pressure (1 atmosphere), and the rotation speed of the mixer (model: B30 type, produced by Guangdong Nanhai Defeng Electric Heating Equipment Factory) was 110 rev / min, added to the reaction kettle (capacity: 500KG, produced by Wuxi Xihe Medical Equipment Factory).

[0028] 2. With 7 kilograms of dodecyldimethylammonium bromide (trade name: benzalkonium bromide, purity: 99%), 6 kilograms of didecyldimethylammonium chloride (purity: 99%) and 2 kilograms Hexadecyldimethylammonium chloride (purity: 99%) was sequentially added to the reactor (capacity: 500KG, ...

Embodiment 2

[0033] A kind of production method of disinfectant of the present invention adopts following processing steps:

[0034] 1. Add 1 kg of glycerol (trade name: glycerol, purity: 99%) to 30 kg of hexamethylenetetramine (trade name: urotropine, purity: 99%), then add 1 kg of poly Hexamethylene guanidine (purity: 99%) was stirred for 1.5 hours under the conditions of normal temperature 25°C and normal pressure (1 atmosphere), and the rotation speed of the stirrer (model: B30 type, produced by Guangdong Nanhai Defeng Electric Heating Equipment Factory) was 105 rpm / minute, join in the reactor (capacity: 500KG, Wuxi Xihe Medical Equipment Factory production).

[0035] 2. With 6 kilograms of dodecyldimethylammonium bromide (trade name: benzalkonium bromide, purity: 99%), 4 kilograms of didecyldimethylammonium chloride (purity: 99%) and 1 kilogram Hexadecyldimethylammonium chloride (purity: 99%) was sequentially added to the reactor (capacity: 500KG, produced by Wuxi Xihe Medical Equi...

Embodiment 3

[0039] A kind of production method of disinfectant of the present invention adopts following processing steps:

[0040] 1. Join 0.5 kg of glycerol (trade name: glycerin, purity: 99%) into 20 kg of hexamethylenetetramine (trade name: urotropine, purity: 99%), then add 0.5 kg of poly Hexamethylene guanidine (purity: 99%) was stirred for 1 hour under the conditions of normal temperature 20°C and normal pressure (1 atmosphere), and the rotation speed of the stirrer (model: B30 type, produced by Guangdong Nanhai Defeng Electric Heating Equipment Factory) was 100 rpm / minute, join in the reactor (capacity: 500KG, Wuxi Xihe Medical Equipment Factory production).

[0041] 2. With 3 kilograms of dodecyldimethylammonium bromide (trade name: benzalkonium bromide, purity: 99%), 2 kilograms of didecyldimethylammonium chloride (purity: 99%) and 0.5 kilograms Hexadecyldimethylammonium chloride (purity: 99%) was sequentially added to the reactor (capacity: 500KG, produced by Wuxi Xihe Medic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com