Method for continuous and batch purification of bacterial magnetic particles

A technology of magnetosomes and bacteria, applied in the field of large-scale purification of bacterial magnetosomes, can solve the problems of discontinuous processing, immune reaction, long purification cycle, etc., and achieve the effect of short cycle, less protein residue and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

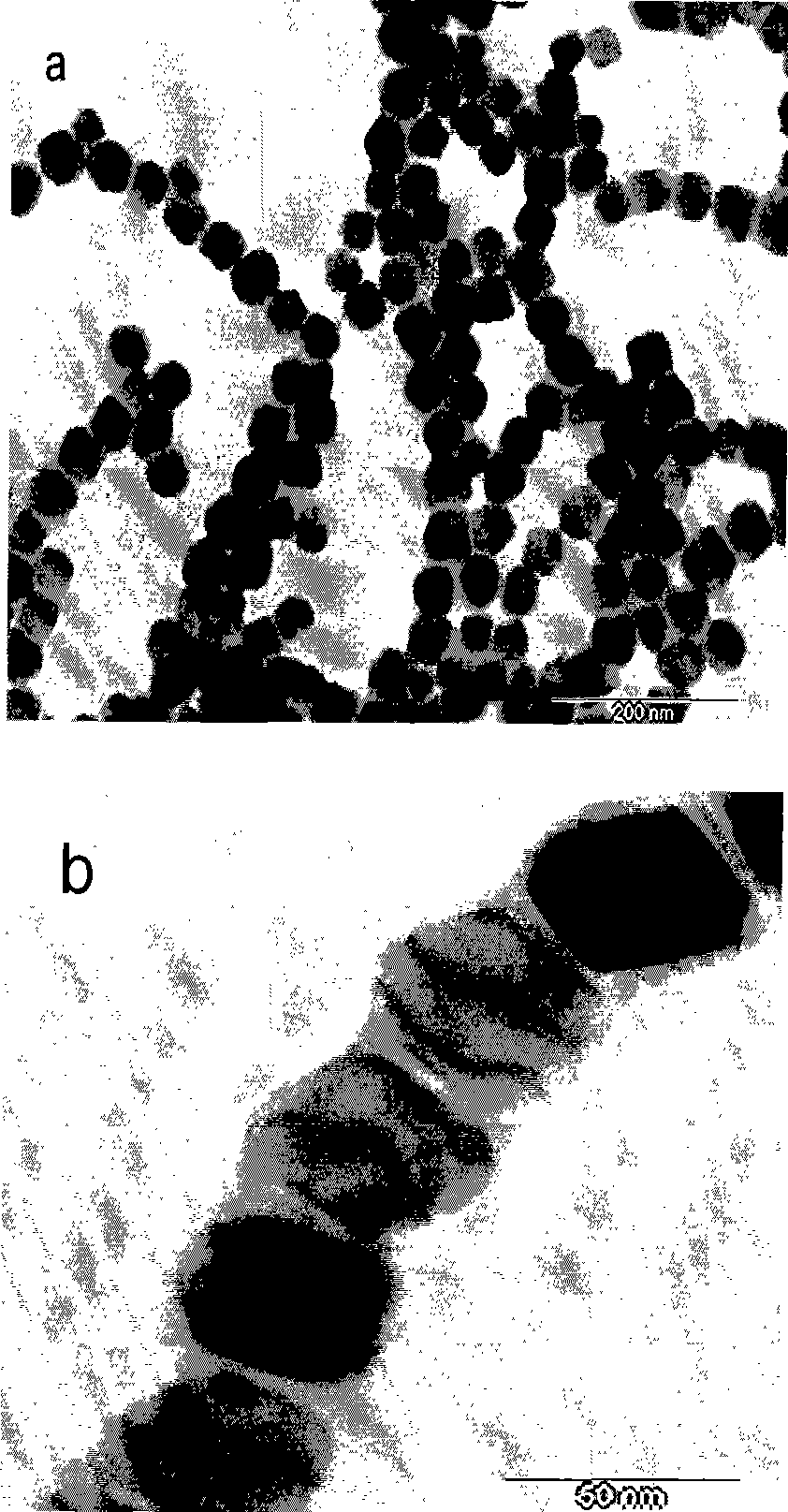

[0032] Example 1 Large-scale purification of bacterial magnetosomes

[0033] Magnetospira MSR-1 (purchased from the German Microorganism Collection (DSMZ)) was taken for activation, and cultured by submerged fermentation until the bacterial density was 10-12OD 565nm . The magnetosomes were purified according to the following steps.

[0034] (1) When the fermentation of magnetotactic bacteria is finished, add PBS buffer solution (0.1M, pH 6.54) 0.1 times the volume of the fermentation broth to the fermenter, and then input the mixed solution into a high-pressure homogenizer to break the cells.

[0035] (2) The broken cell suspension enters the magnetic chromatography system to separate and wash the magnetosomes. When all the broken suspension of the bacteria enters the magnetic chromatography separation system and the magnetosomes are adsorbed on the chromatography column (the discarded suspension is discharged from the system). Pump 6 times the volume (6 times the column vo...

Embodiment 2

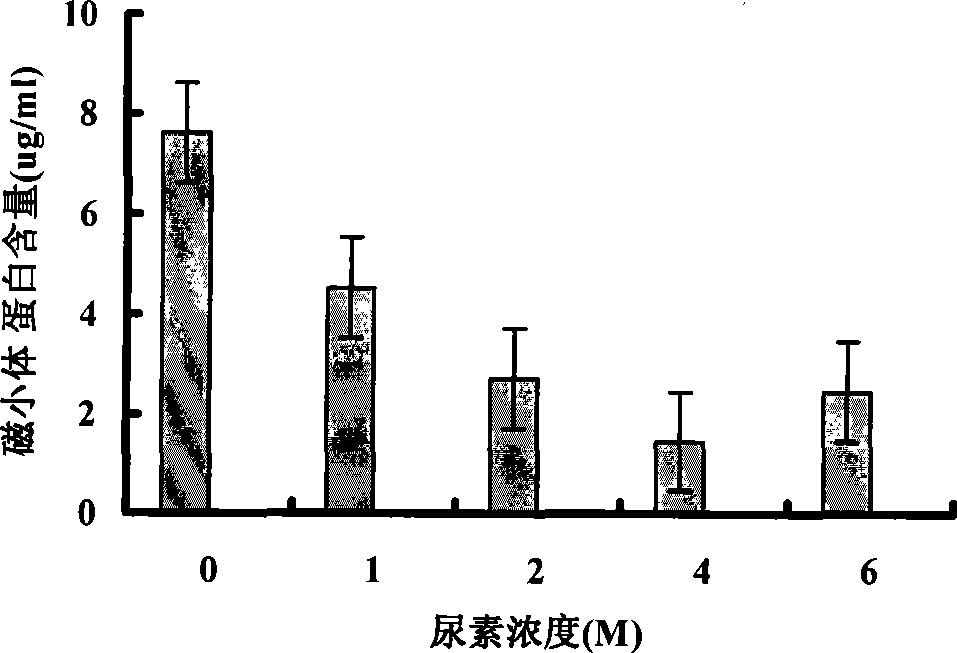

[0041] Example 2 Detection of residual protein in each step of the purification process

[0042] Magnetotactic bacteria MS-1 (Magnetospirillum magnetotactic) (purchased from DSMZ) was cultivated by submerged fermentation culture method to a bacterial density of 10-12OD 565nm . Then purify according to the following steps to prepare magnetosomes.

[0043] (1) When the fermentation of magnetotactic bacteria is finished, add PBS buffer solution (0.1M, pH 6.54) 0.1 times the volume of the fermentation broth to the fermenter, and then input the mixed solution into a high-pressure homogenizer to break the cells.

[0044] (2) The broken cell suspension enters the magnetic chromatography system to separate and wash the magnetosomes. When all the broken suspension of the bacteria enters the magnetic chromatography separation system and the magnetosomes are adsorbed on the chromatography column (the discarded suspension is discharged from the system). Pump into the PBS buffer solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com