Preparation of aluminum doped zinc oxide nano-wire

An aluminum-doped zinc oxide and nanowire technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of limiting the use range of the film, reducing the performance of the film, and high cost of ITO, achieving low cost, simple equipment, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Use a silicon wafer as the receiving substrate, and clean the silicon wafer in alcohol and acetone respectively.

[0020] 2. Use Zn powder and Al powder as the evaporation source, and place them adjacent to each other in an aluminum oxide boat; place the cleaned silicon wafer directly above the evaporation source, with a vertical distance of 1 mm from the source, and then place the boat in a horizontal in a tube furnace.

[0021] 3. Heat the tube furnace to 800°C and keep it warm for 45 minutes. During the whole growth process, the furnace chamber was always filled with 40ml / min argon. After the growth, the tube furnace was naturally cooled to room temperature. The sample was taken out, and Al-doped ZnO nanowires were deposited on the surface of the silicon wafer.

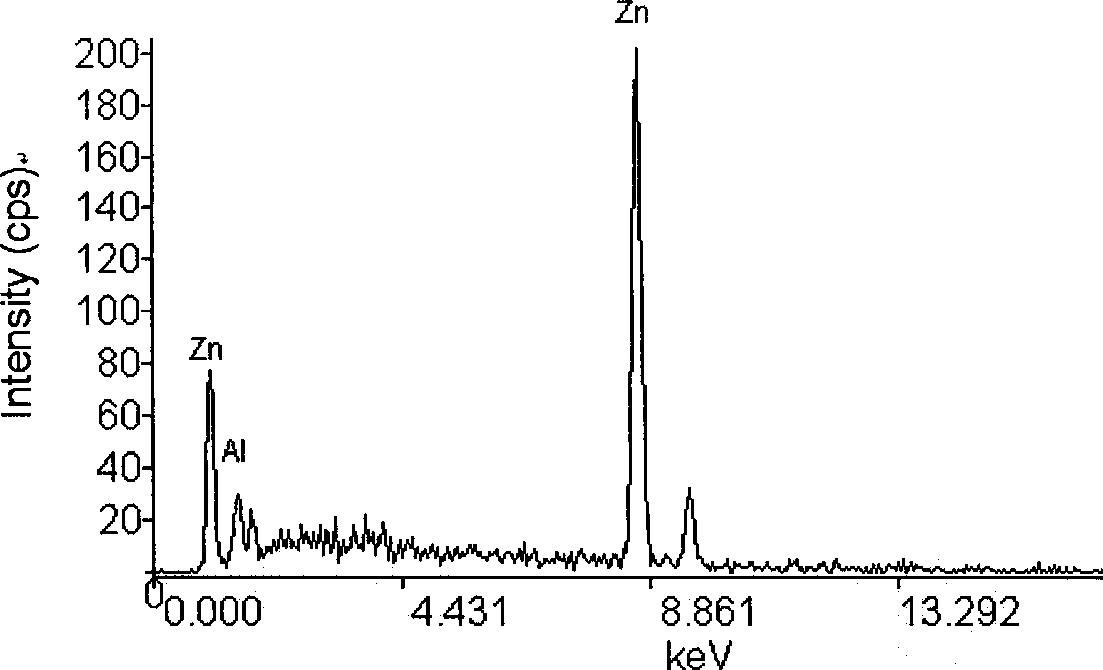

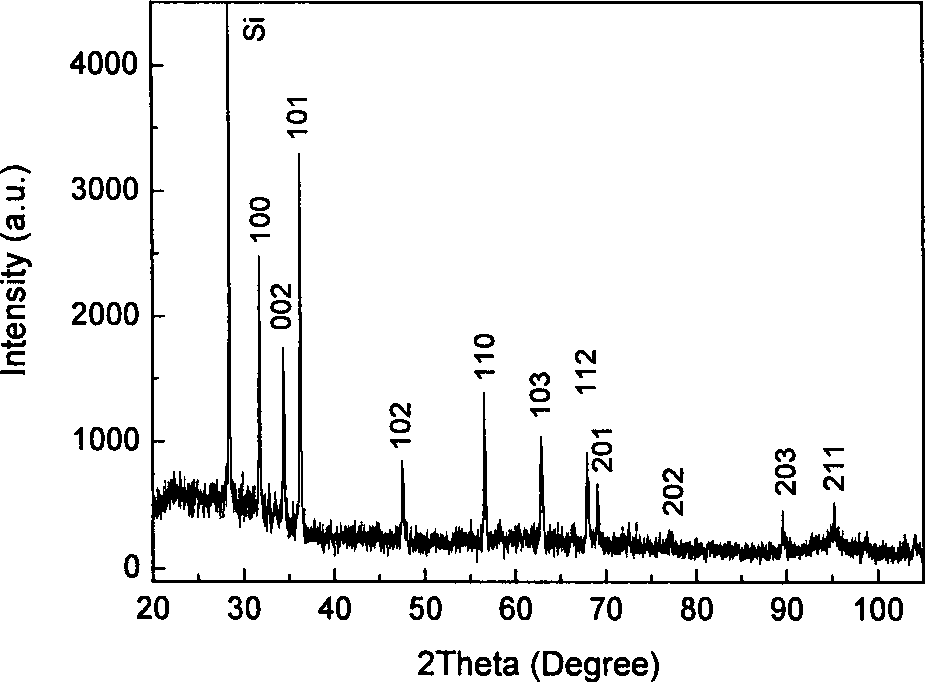

[0022] The scanning electron microscope results of the product are as follows figure 1 As shown, the product consists of nanowires. The diameter of the nanowire is 40-370 nm, and the length is 30-150...

Embodiment 2

[0024] 1. Use a silicon wafer as the receiving substrate, and clean the silicon wafer in alcohol and acetone respectively.

[0025] 2. Use Zn powder and Al powder as the evaporation source, and place them adjacent to each other in an aluminum oxide boat; place the cleaned silicon wafer directly above the evaporation source, with a vertical distance of 1 mm from the source, and then place the boat in a horizontal in a tube furnace.

[0026] 3. Heat the tube furnace to 810°C and keep it warm for 50 minutes. During the whole growth process, the furnace chamber was always filled with 50ml / min argon. After the growth, the tube furnace was naturally cooled to room temperature. The sample was taken out, and Al-doped ZnO nanowires were deposited on the surface of the silicon wafer. The doping content of Al in the Al-doped ZnO nanowires is 2 at.%.

Embodiment 3

[0028] 1. Use a silicon wafer as the receiving substrate, and clean the silicon wafer in alcohol and acetone respectively.

[0029] 2. Use Zn powder and Al powder as the evaporation source, and place them adjacent to each other in an aluminum oxide boat; place the cleaned silicon wafer directly above the evaporation source, with a vertical distance of 2 mm from the source, and then place the boat in a horizontal in a tube furnace.

[0030] 3. Heat the tube furnace to 850°C and keep it warm for 60 minutes. During the whole growth process, the furnace chamber was always filled with 50ml / min argon. After the growth, the tube furnace was naturally cooled to room temperature. The sample was taken out, and Al-doped ZnO nanowires were deposited on the surface of the silicon wafer. The doping content of Al in the Al-doped ZnO nanowires is 7 at.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com