Method of manufacturing polycarbonate/polyester alloy

A polycarbonate and polyester alloy technology, which is used in the preparation of polymer alloys and the preparation of polycarbonate/polyester alloys, can solve problems such as difficulty in processing and molding, decrease in polyester crystallization rate and crystallinity, and stress cracking. , to increase the apparent volume fraction, reduce the thickness of the matrix layer, and stop the growth of cracks

Active Publication Date: 2011-01-05

SHANGHAI JIAOTONG UNIV +1

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, polycarbonate has some disadvantages: high melt viscosity, difficult processing and molding, especially large-scale products, prone to stress cracking, high notch sensitivity, solvent resistance, and expensive, so that the application of polycarbonate is restricted. certain restrictions

However, although the impact properties of the alloy materials prepared by the current compatibilization and toughening system have been improved to varying degrees, it often leads to a decrease in the crystallization rate and crystallinity of the polyester, and the thermal deformation temperature, tensile strength, and bending strength of the material , flexural modulus and dimensional stability are correspondingly reduced to varying degrees, which greatly limits the wide application of this alloy material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

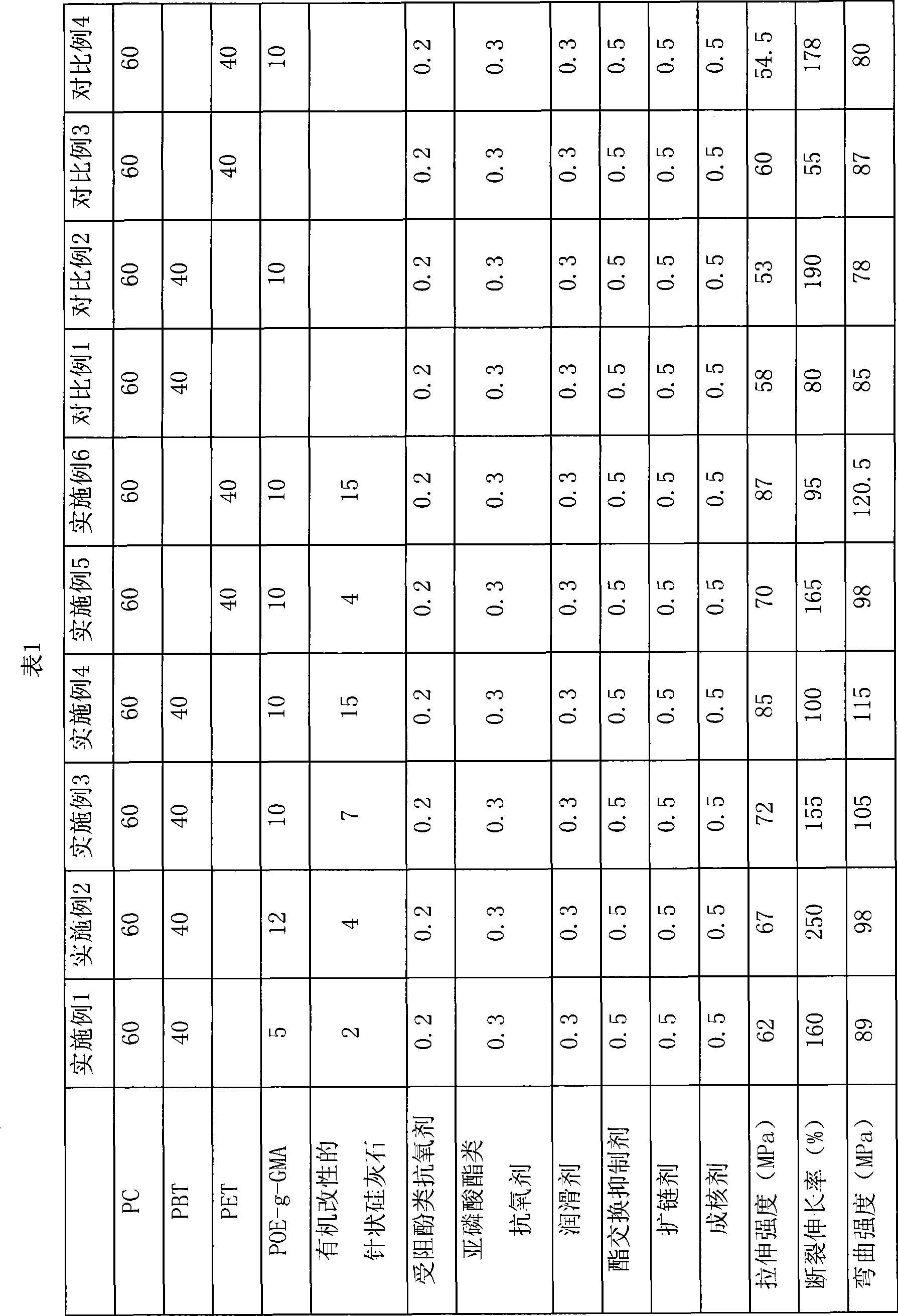

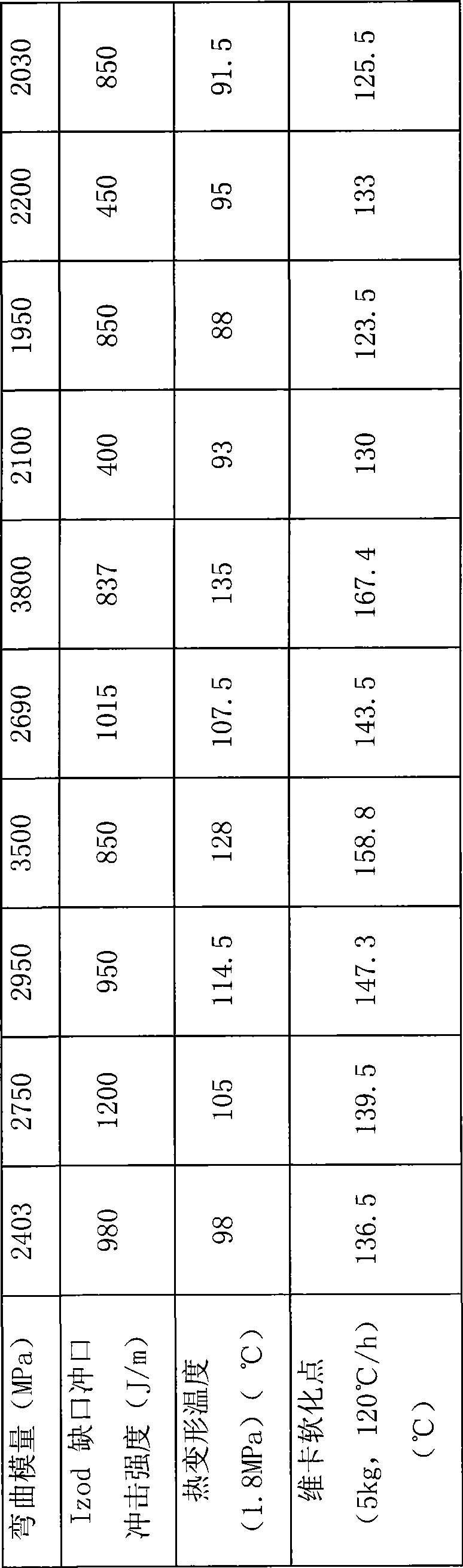

Embodiment 1-4

Embodiment 5-6

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied incars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Description

A kind of preparation method of polycarbonate / polyester alloy technical field The invention relates to a preparation method of a polymer alloy, in particular to a preparation method of a polycarbonate / polyester alloy, which can be used for automotive interior and exterior decoration parts, household appliances, IT and other industrial products, and belongs to the technical field of polymer processing. Background technique Polycarbonate (PC) is an engineering plastic with excellent performance. It has the advantages of outstanding impact toughness, wide service temperature, good electrical insulation performance and dimensional stability. It has been applied in various industrial sectors, especially in automobiles. The manufacturing industry and the electrical and electronic industry are its two broad markets. However, polycarbonate has some disadvantages: high melt viscosity, difficult processing and molding, especially large-scale products, prone to stress cracking, high ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L69/00C08L51/06C08K13/06C08K9/04B29B9/12B29C47/92B29C47/10C08L67/00B29C48/40B29C48/92

CPCB29C48/92B29C2948/92704B29C48/40B29C2948/92561B29C2948/9259B29C2948/92885B29C2948/92895B29C2948/9298

Inventor 刘春艳周持兴俞炜李红军白雪峰

Owner SHANGHAI JIAOTONG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com