Back plate of solar cell

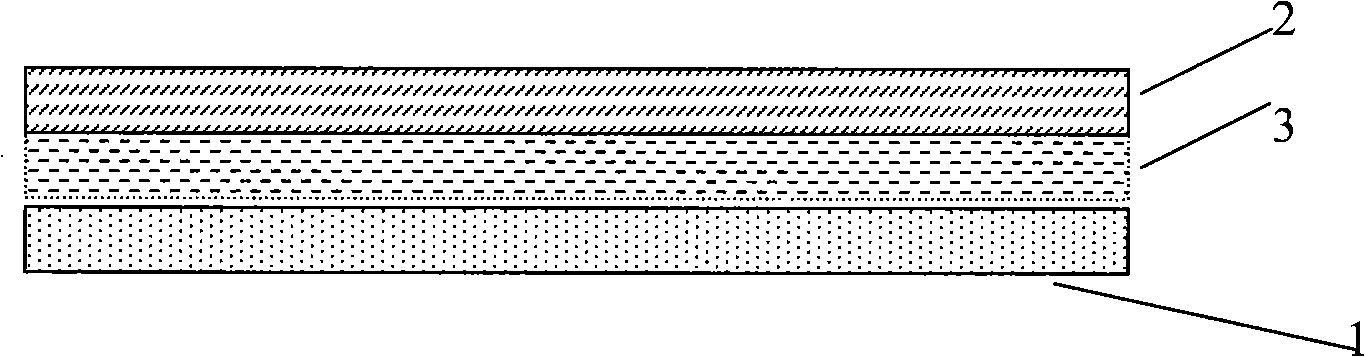

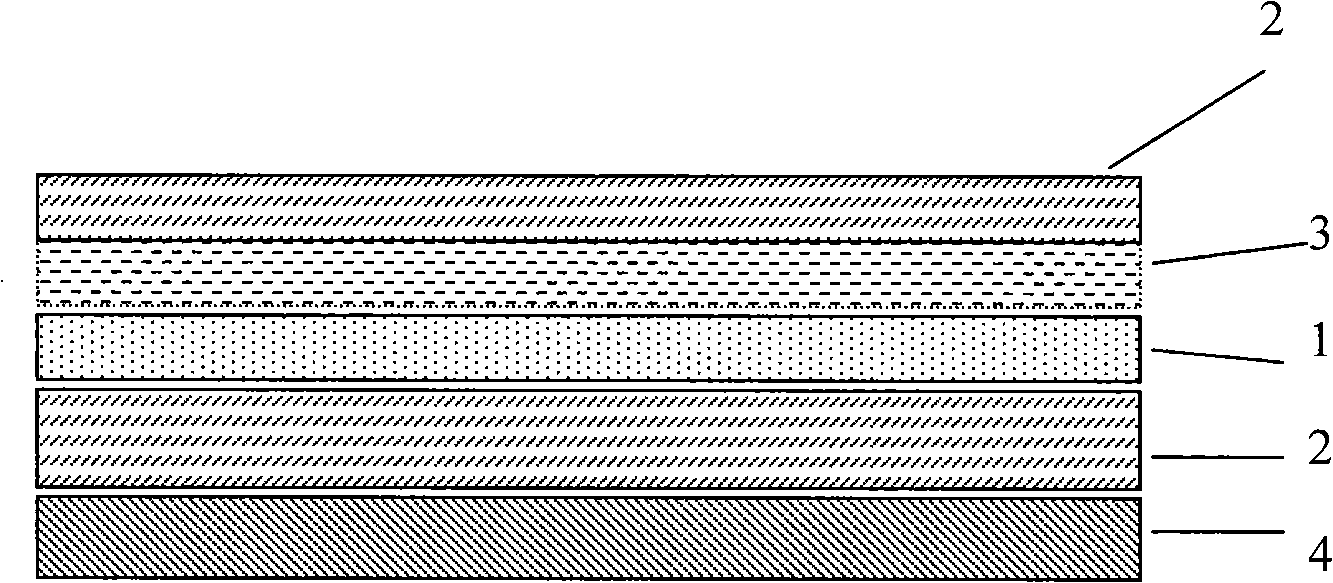

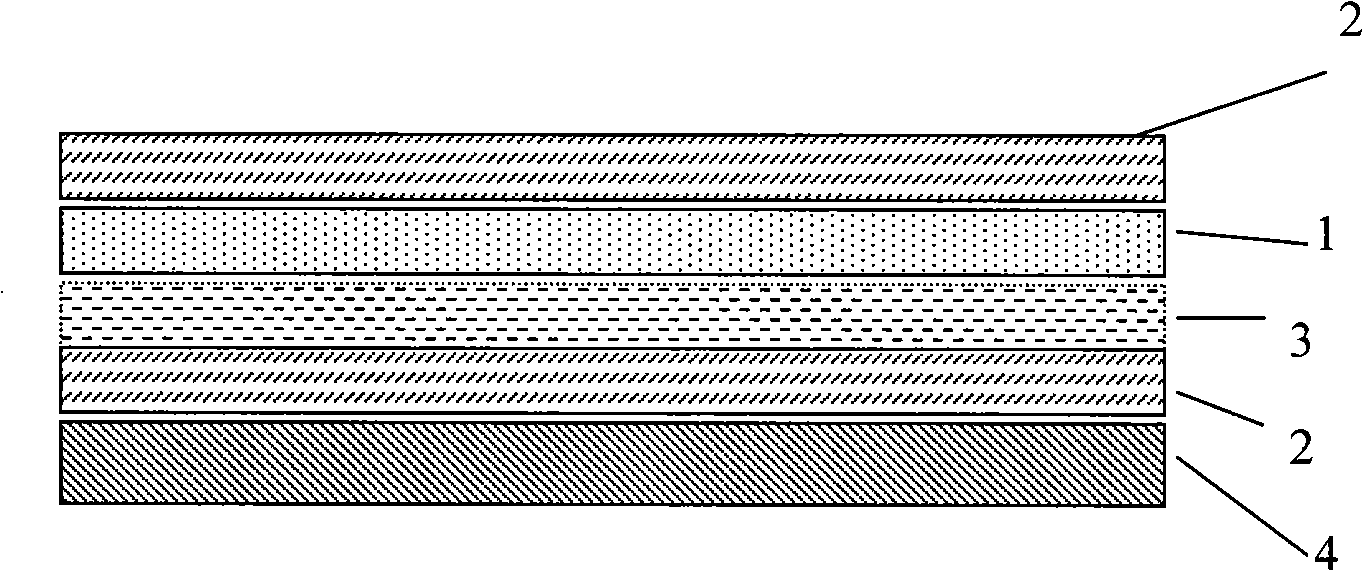

A technology for solar cells and backsheets, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of general water vapor barrier effect and low adhesive strength, and achieve strong weather resistance, high barrier performance, and high adhesive strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 25 parts of polyvinylidene fluoride (manufactured by Aldrich);

[0034] 3 parts of hydroxyl modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin;

[0035] (manufactured by China Lucky Film Group Corporation)

[0036] 2 parts of polytetrafluoroethylene (made by Solvay Solexis);

[0037] Titanium dioxide powder (made by Du PONT) 0.2 part;

[0038] Butanone 20 parts;

[0039] 50 parts of ethyl acetate;

[0040] Add 20 parts of methyl ethyl ketone and 50 parts of ethyl acetate into a container equipped with a stirring device, start stirring, and mix 25 parts of polyvinylidene fluoride, 3 parts of hydroxyl-modified polyvinylidene fluoride-tetrafluoroethylene-hexa Fluoropropylene resin, 2 parts of polytetrafluoroethylene powder and 0.2 parts of titanium dioxide powder were added to the solvent in sequence, and stirred for 60 minutes to obtain a weather-resistant layer coating solution.

[0041] Coat one side of the substrate PET film with a poly...

Embodiment 2

[0043] 40 parts of polytetrafluoroethylene (made by Aldrich);

[0044] Amino-modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin

[0045] (manufactured by China Lucky Film Group Corporation) 2 copies;

[0046] Polyamide particles (made by Solvay Solexis) 3 parts;

[0047] 0.3 parts of quartz particles (manufactured by Du PONT);

[0048] 55 parts of butyl acetate;

[0049] Add 55 parts of butyl acetate into a container equipped with a stirring device, start stirring, and mix 40 parts of polytetrafluoroethylene and 2 parts of amine-modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin , 3 parts of polyamide particles and 0.3 parts of quartz particles were sequentially added into the solvent, and stirred for 50 minutes to prepare a weather-resistant layer coating liquid.

[0050] Coat one side of the substrate PEN film with a polyurethane adhesive (manufactured by DYMAX), dry it with hot air and compound it with a metal alumin...

Embodiment 3

[0052] 45 parts of polyvinylidene fluoride-hexafluoropropylene (manufactured by Dyneon);

[0053] Aziridine-modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin

[0054] (manufactured by China Lucky Film Group Corporation) 2.5 copies;

[0055] 2.5 parts of polyacrylate polymer particles (made by solvay solexis);

[0056] 0.1 parts of mica particles (manufactured by Du PONT);

[0057] 50 parts of toluene;

[0058] Add 50 parts of toluene to a container equipped with a stirring device, start stirring, and mix 45 parts of polyvinylidene fluoride-hexafluoropropylene, 2.5 parts of polyvinylidene fluoride-tetrafluoroethylene modified by aziridine - Hexafluoropropylene resin, 2.5 parts of polyacrylate polymer particles and 0.1 part of mica particles were sequentially added to the solvent and stirred for 80 minutes to prepare a weather-resistant layer coating liquid.

[0059] Epoxy adhesive (manufactured by Hexion) is coated on one side of the substrate P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com