NiAl intermetallic compound porous material and preparation method thereof

An intermetallic compound and porous material technology, which is applied in the field of NiAl intermetallic compound porous materials and their preparation, can solve the problems of complex composition of porous materials, no reports of porous materials, and complicated processes, achieve excellent high-temperature mechanical properties, improve comprehensive performance, low energy consumption for preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Preparation of NiAl intermetallic compound porous material of the present invention

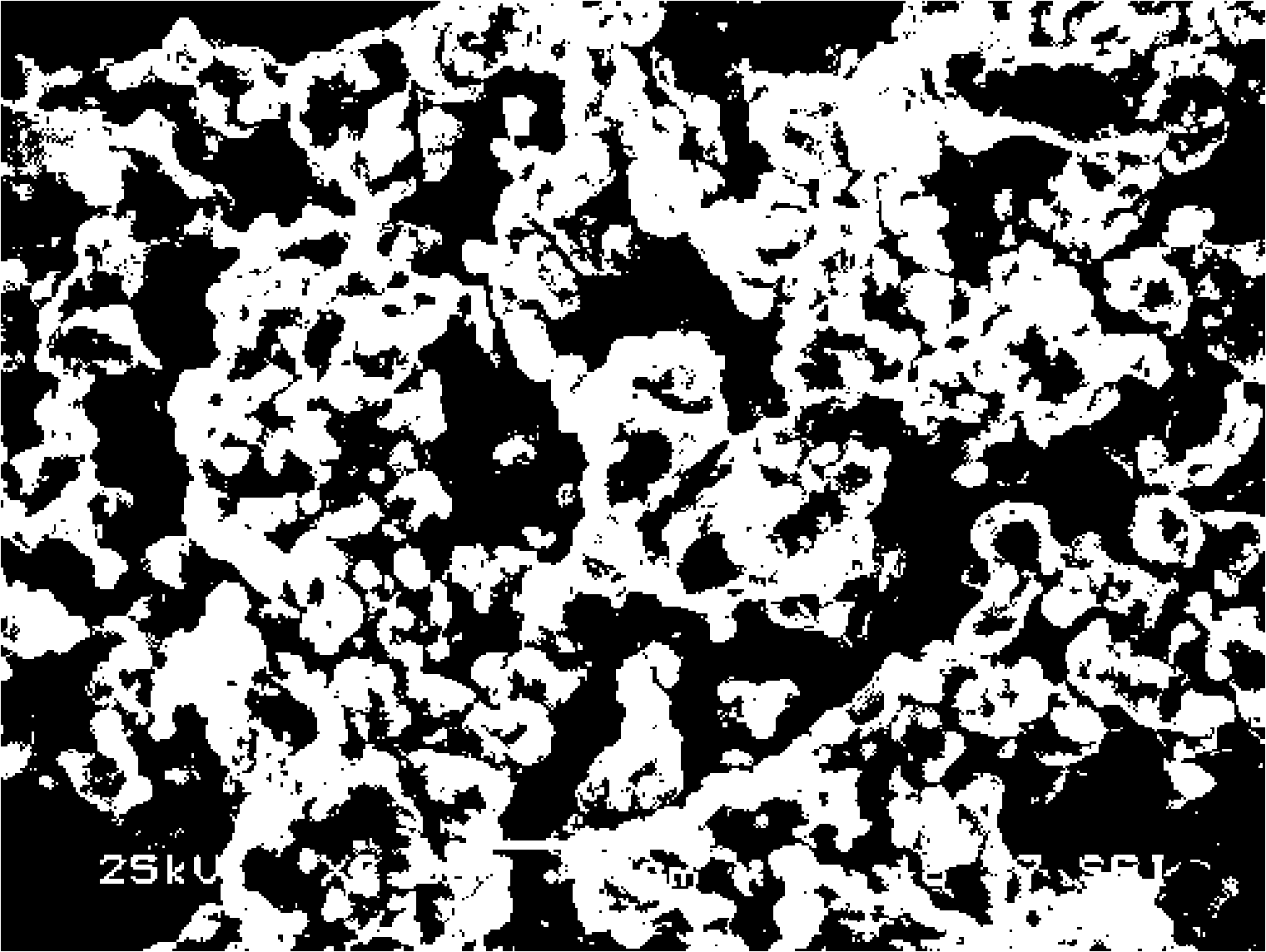

[0024] Using Ni powder and Al powder with an average particle size of 80 μm and 90 μm respectively, mixing according to the composition ratio of Ni-15wt% Al (that is, the weight ratio of Al is 15%), and then performing ordinary molding under a pressure of 400MPa Forming into a sheet-like green body. The reaction synthesis adopts segmented vacuum pressureless sintering process, and the vacuum degree is 1.0~1.0×10 -1 Pa, first rise to 530°C with a heating rate of 5°C / min, and the holding time is 60min; then rise to 1250°C at a heating rate of 5°C / min, and hold for 60min; cool with the furnace to obtain the NiAl intermetallic compound of the present invention porous material. Its microstructure see figure 1 .

[0025] It is determined that the porosity of the NiAl intermetallic compound porous material is 42%, and the maximum pore diameter is 32 μm.

Embodiment 2

[0026] Example 2 Preparation of NiAl intermetallic compound porous material of the present invention

[0027] Using Ni powder and Al powder with an average particle size of 10 μm and 5 μm respectively, mixing according to the composition ratio of Ni-20wt% Al, and then performing ordinary compression molding under a pressure of 100 MPa to make a sheet-shaped green body. The reaction synthesis adopts segmented vacuum pressureless sintering process, and the vacuum degree is 1.0×10 -1 ~1.0×10 -2 Pa, first rise to 550°C with a heating rate of 4°C / min, and the holding time is 90min; then rise to 1100°C at a heating rate of 7°C / min, and hold for 90min; cool with the furnace to obtain the NiAl intermetallic compound of the present invention porous material.

[0028] It is determined that the porosity of the NiAl intermetallic compound porous material is 35%, and the maximum pore diameter is 15 μm.

Embodiment 3

[0029] Example 3 Preparation of NiAl intermetallic compound porous material of the present invention

[0030] Using Ni powder and Al powder with an average particle size of 60 μm and 50 μm respectively, mixing according to the composition ratio of Ni-30wt% Al, and then performing cold isostatic pressing under a pressure of 200 MPa to form a tubular body. The reaction synthesis adopts segmented vacuum pressureless sintering process, and the vacuum degree is 1.0×10 -1 ~1.0×10 -2 Pa, first rise to 470°C with a heating rate of 3°C / min, and the holding time is 120min; then rise to 1000°C at a heating rate of 8°C / min, and hold for 90min; cool with the furnace to obtain the NiAl intermetallic compound of the present invention porous material.

[0031] It has been determined that the porosity of the NiAl intermetallic compound porous material is 43%, and the maximum pore diameter is 22 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum aperture | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com