Method for improving carbon steel solidification structure using high voltage electropulse

A technology of high-voltage electric pulse and solidification structure is applied in the field of improving the coarse grains in the solidification structure, which can solve the problems of small electric parameters in electric pulse processing, and achieve the effects of convenient operation, continuous production, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

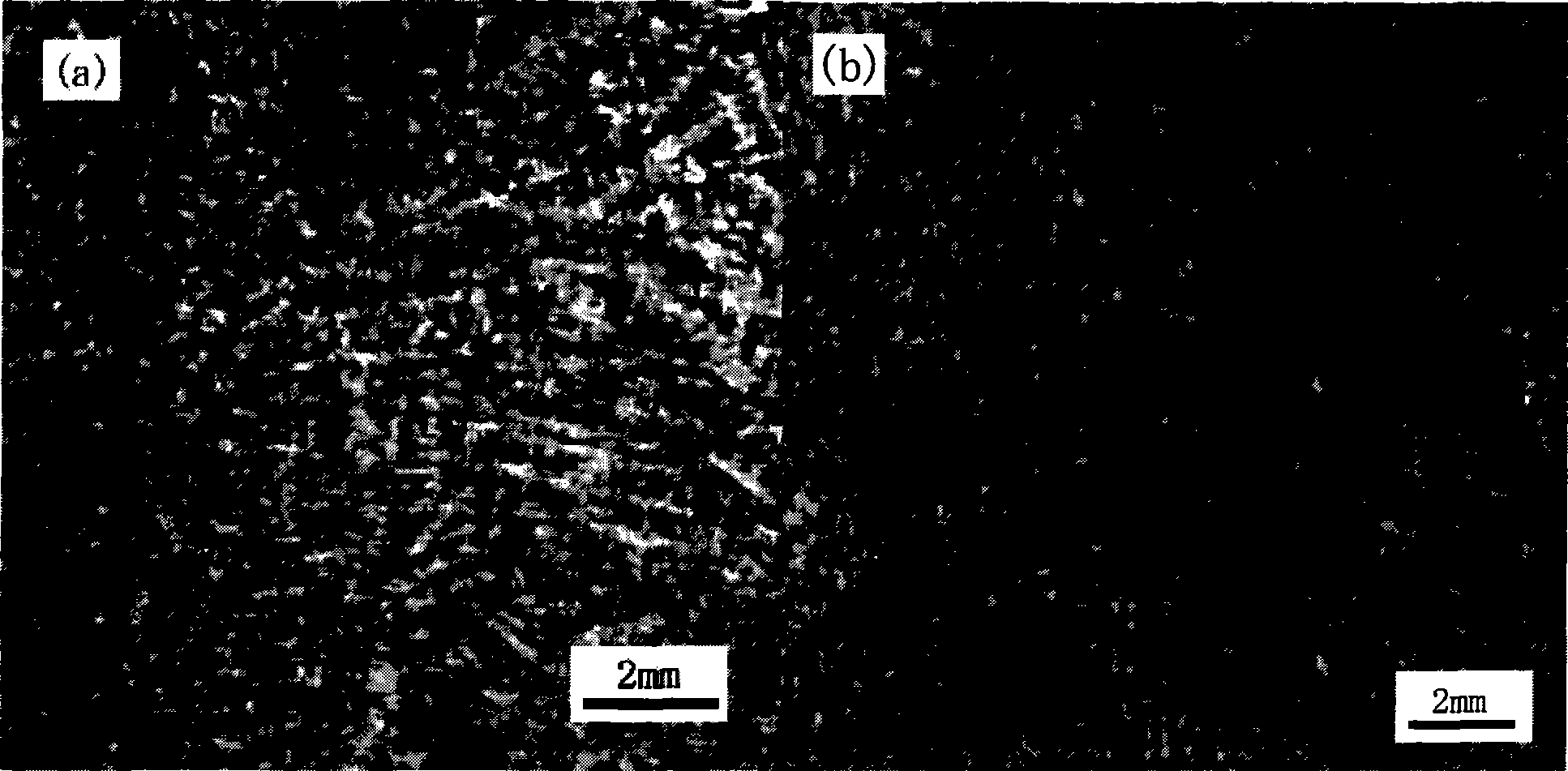

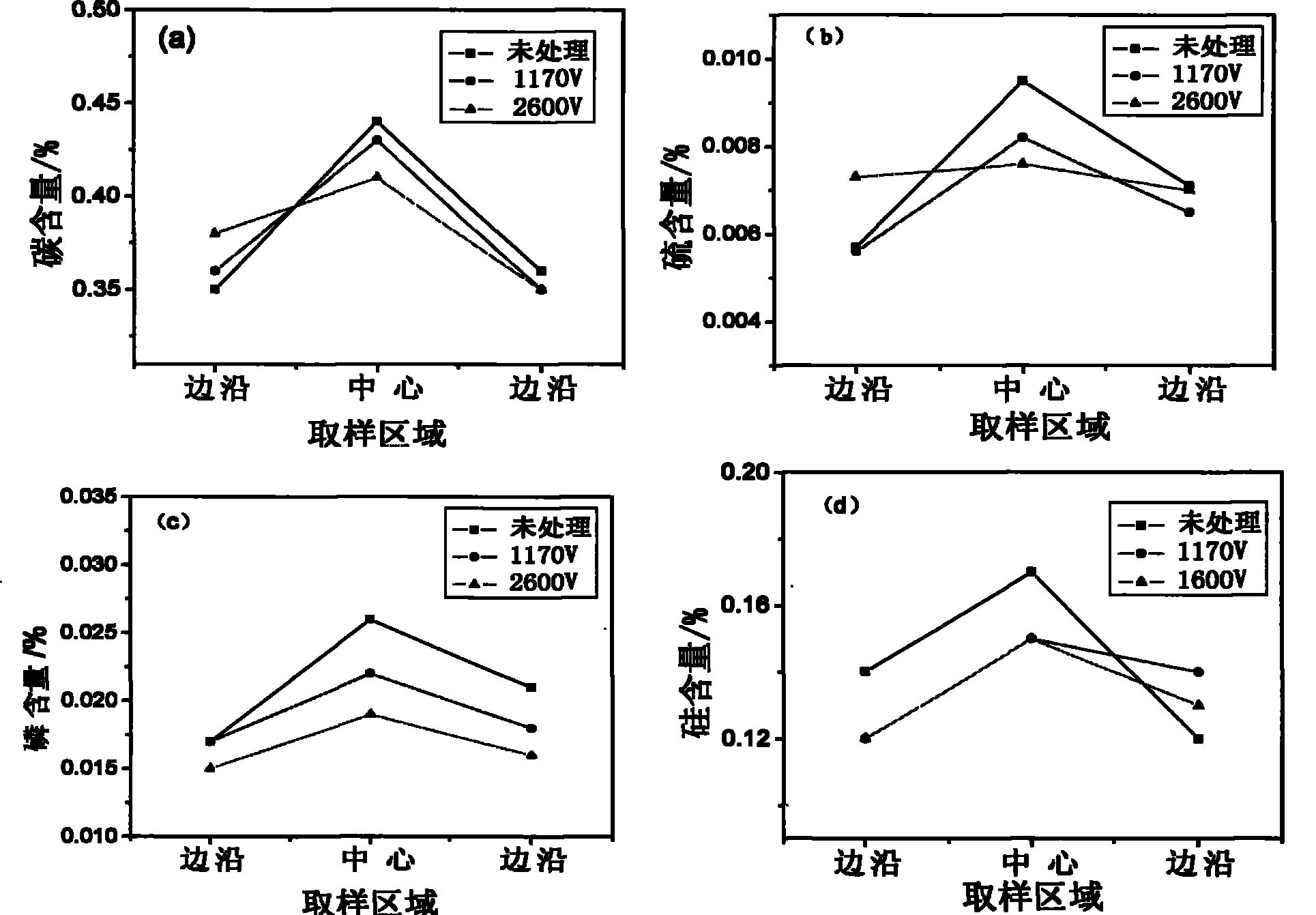

[0020] The material of this embodiment is 45 steel (the main chemical components are: 0.43% C, 0.58% Mn, 0.22% Si, 0.003% S, 0.02% P), which is melted by an intermediate frequency induction furnace to make the molten steel temperature reach about 1540°C. And keep the temperature for 5min to make the molten steel composition and temperature uniform. After deoxidizing with aluminum wire, it is cast into a square mold (dimension 75×75×75mm 3 ), start the pulse signal generator and conduct electrical pulse processing until the molten steel is completely solidified. The main electrical parameters are: voltage 2600V, frequency 0.86Hz (charging time 0.73s, discharging time 0.43s), and capacitor capacity 200μF. Figures (a) and (b) are the macroscopic solidification structure of 45 steel without electric pulse treatment and after 2600V electric pulse treatment. It can be clearly seen from the figure that after the electrical pulse treatment, the coarse dendrites are refined into fine and...

Embodiment 2

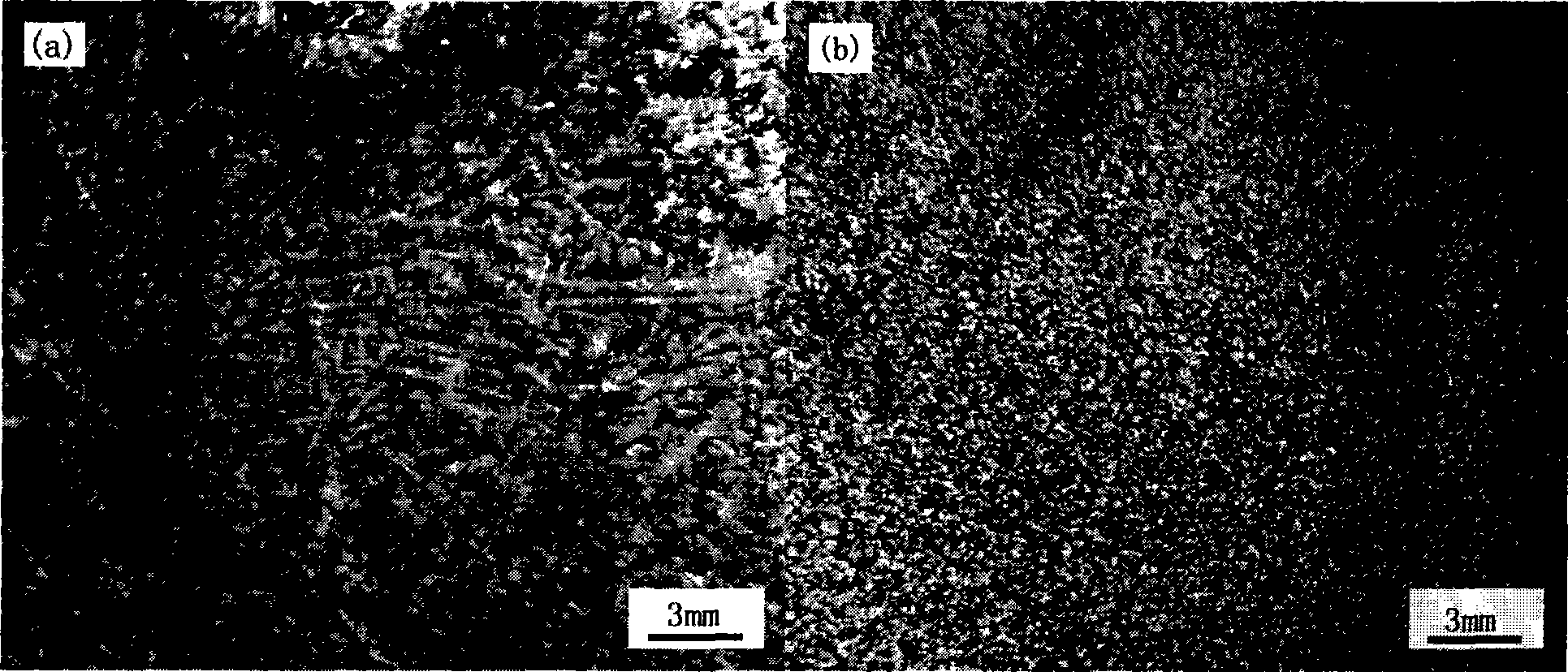

[0022] The material of this embodiment is 45 steel (its main chemical composition is: 0.43%C-0.58%Mn-0.22%Si-0.003%S-0.02%P). The pre-weighed 45 steel is added to the intermediate frequency induction furnace, and it is energized. Heat and melt the molten steel so that the temperature of the molten steel reaches about 1540℃, and keep it for 5 minutes to make the composition and temperature of the molten steel uniform. After deoxidizing with aluminum wire, directly insert the electrode into the molten steel of the induction furnace, turn off the induction furnace power switch, and then start the pulse signal generator The main electrical parameters are: voltage 2900V, frequency 0.96Hz (charging time 0.73s, discharging time 0.43s), capacitor capacitance 300μF, electric pulse treatment before solidification, treatment time 60s, and cast the treated molten steel to pre-use In the square mold of the combination of thermal insulation board (size 75×75×75mm 3 ). image 3 (a) and (b) are...

Embodiment 3

[0024] The material of this embodiment is 30Mn steel (its main chemical composition is: 0.28%C-0.84%Mn-0.32%Si-0.028%S-0.032%P), first use an intermediate frequency induction furnace (CW-1JJ) to melt the 30Mn steel , Make the temperature of molten steel reach about 1560℃, keep it for 5min, deoxidize with aluminum wire and cast into a heat-insulating plate mold with better heat preservation effect, quickly insert the electrode, turn on the pulse signal generator for electric pulse treatment, until the molten steel is completely solidified until. The parameters of the pulse signal generator are: the pulse voltage is 3670V, the frequency is 1.14Hz (charge time 0.58s, discharge time 0.30s), and the capacitor capacitance is 500μF.

[0025] Figure 4 (a) and (b) are the macroscopic solidification structure of 30Mn steel without electric pulse treatment and 3670V electric pulse treatment. It can be clearly seen from the figure that after the electric pulse treatment, the coarse dendri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com