Anti-corrosion and heat tinting composite surface treating method for steel

A composite surface treatment and anti-corrosion technology, which is applied in the direction of surface polishing machine tools, coatings, metal material coating processes, etc., can solve the problems of single surface color and poor decoration, and achieve low raw material costs, low product costs, and adaptability wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: blue steel pipe

[0028] 1. Immerse the No. 45 steel pipe blank in 5% dilute hydrochloric acid for 10 minutes to remove rust, and then polish it to make the surface roughness less than Ra0.8;

[0029] 2. Put it into the tempering furnace to preheat to 320 degrees Celsius and keep it warm for 30 minutes;

[0030] 3. Put it into a 25KW well-type atmosphere furnace, the flow rate of ammonia gas is 1.2 cubic meters per hour, the amount of ethanol drops is 80 drops per minute, the reaction temperature is 570°C, the reaction time is 2 hours, and the furnace is water-cooled;

[0031]4. Fine polishing, first vibrating polishing, and then fine polishing with hemp wheel + cloth wheel to make the surface roughness less than Ra0.4, remove grease, use sodium hydroxide 60-80g / l, sodium phosphate 20-40g / l, silicic acid Sodium 3-10g / l, total alkalinity (equivalent to NaOH) 65-100g / l, temperature 70-90°C, until exhausted;

[0032] 5. For tempering and oxidation coloring, pr...

Embodiment 2

[0036] Example 2: golden yellow sofa legs

[0037] 1. The obtained blank has been derusted, so the derusting process is omitted. First, the surface of the stamped blank of No. 23 steel is polished to obtain a smooth surface, so that the surface roughness is less than Ra0.8;

[0038] 2. Put it into the tempering furnace to preheat to 320 degrees Celsius and keep it warm for 30 minutes;

[0039] 3. Put it into a salt bath furnace, carry out nitriding treatment at 570 degrees for 1.5 hours, take it out of the furnace to cool it in water, and then wash it in warm water at 60 degrees to remove the residual nitride salt on the surface;

[0040] 4. Fine polishing, first vibrating polishing, and then fine polishing with hemp wheel + cloth wheel to make the surface roughness less than Ra0.4, remove grease, use sodium hydroxide 60-80g / l, sodium phosphate 20-40g / l, silicic acid Sodium 3-10g / l, total alkalinity (equivalent to NaOH) 65-100g / l, temperature 70-90°C, until exhausted;

[004...

Embodiment 3

[0045] Example 3: golden yellow sofa legs

[0046] 1. The obtained blank has been derusted, so the derusting process is omitted. First, the surface of the stamped blank of No. 23 steel is polished to obtain a smooth surface, so that the surface roughness is less than Ra0.8;

[0047] 2. Put it into the tempering furnace to preheat to 320 degrees Celsius and keep it warm for 30 minutes;

[0048] 3. Put it into a salt bath furnace, carry out nitriding treatment at 570 degrees for 1.5 hours, take it out of the furnace to cool it in water, and then wash it in warm water at 60 degrees to remove the residual nitride salt on the surface;

[0049] 4. Fine polishing, first vibrating polishing, and then fine polishing with hemp wheel + cloth wheel to make the surface roughness less than Ra0.4, remove grease, use sodium hydroxide 60-80g / l, sodium phosphate 20-40g / l, silicic acid Sodium 3-10g / l, total alkalinity (equivalent to NaOH) 65-100g / l, temperature 70-90°C, until exhausted;

[005...

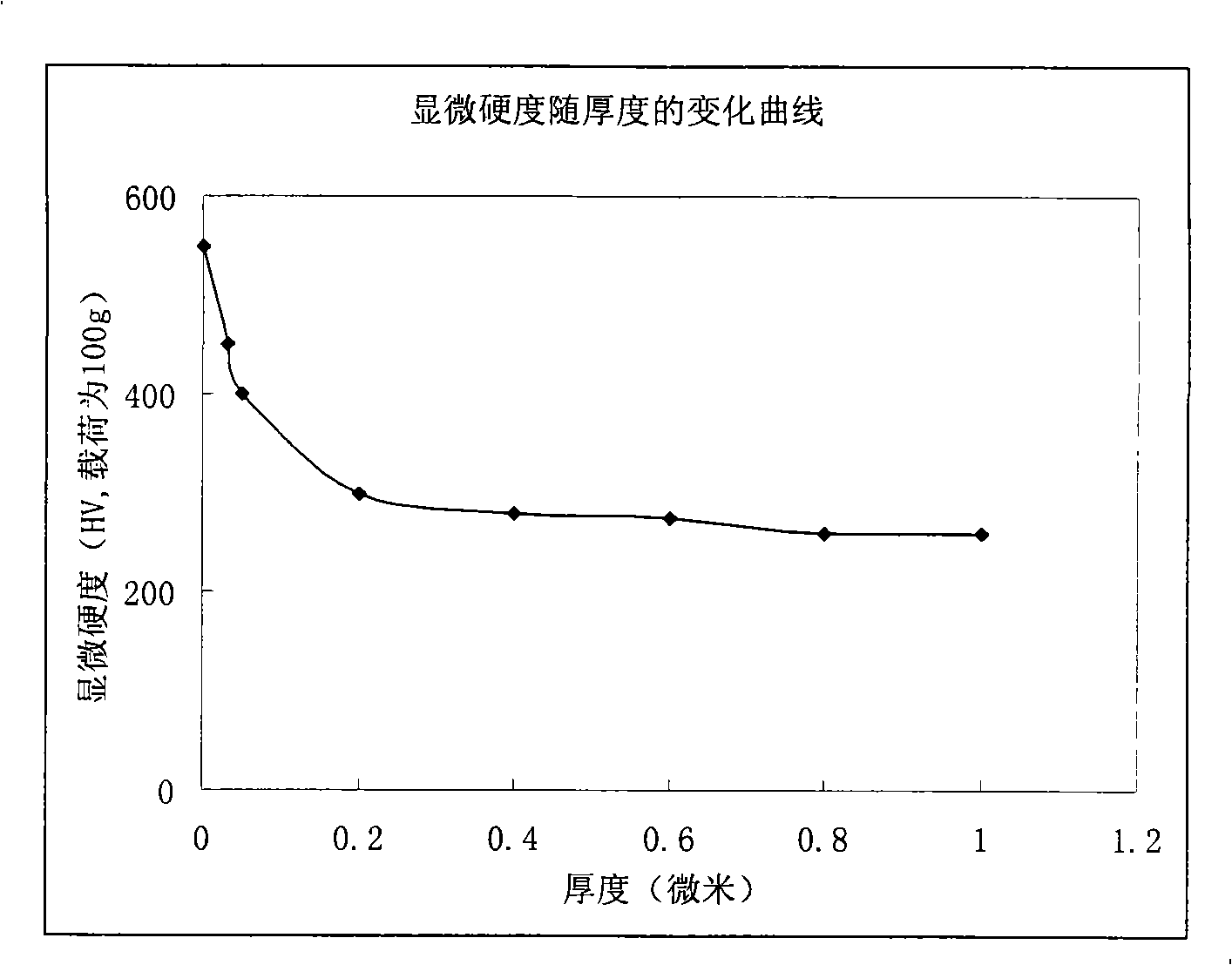

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com