R-Fe-B porous magnet and method for producing the same

A manufacturing method, porous technology, applied in the direction of inductor/transformer/magnet manufacturing, permanent magnet manufacturing, magnetic objects, etc., can solve the problem of high DR processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

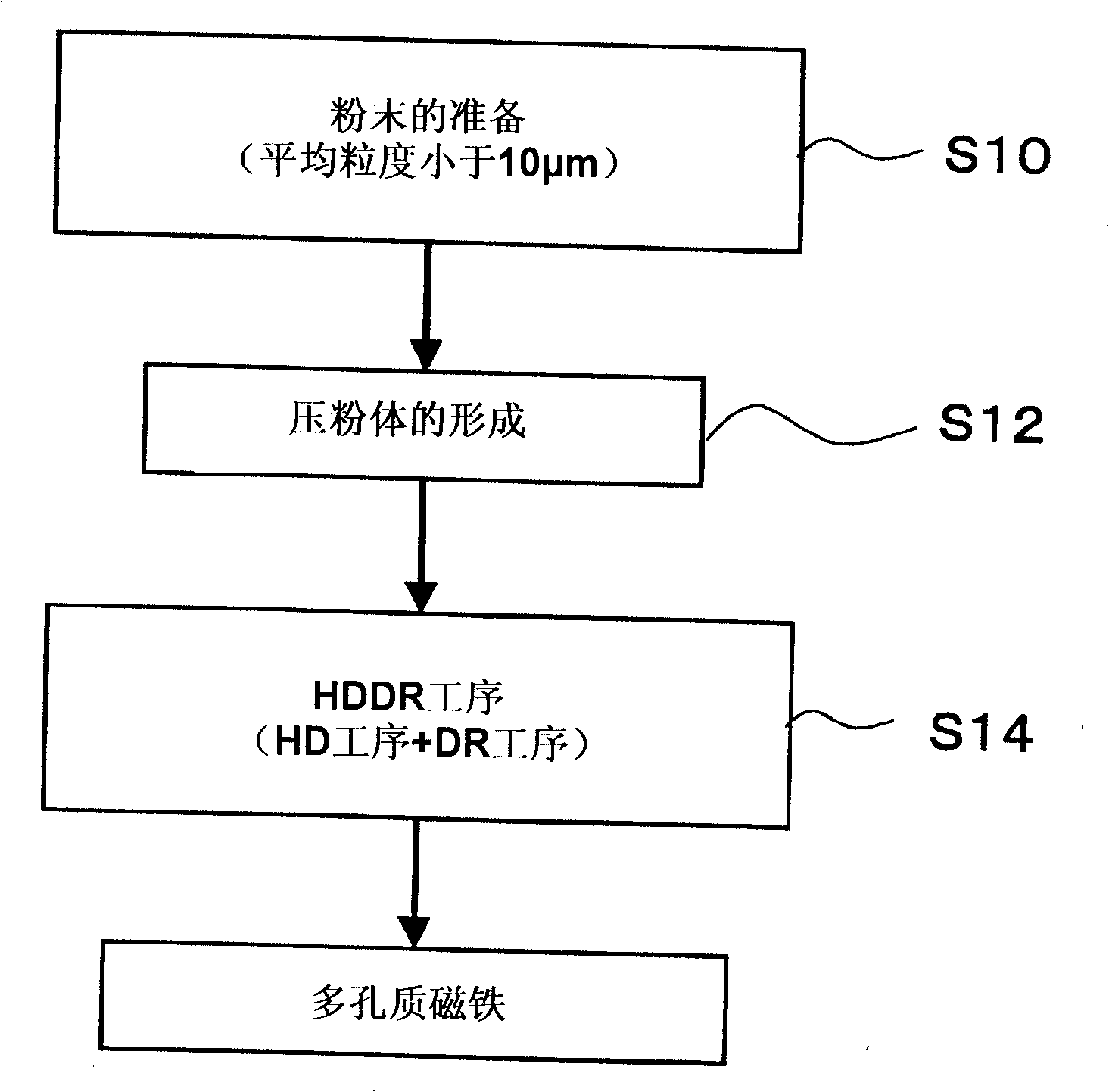

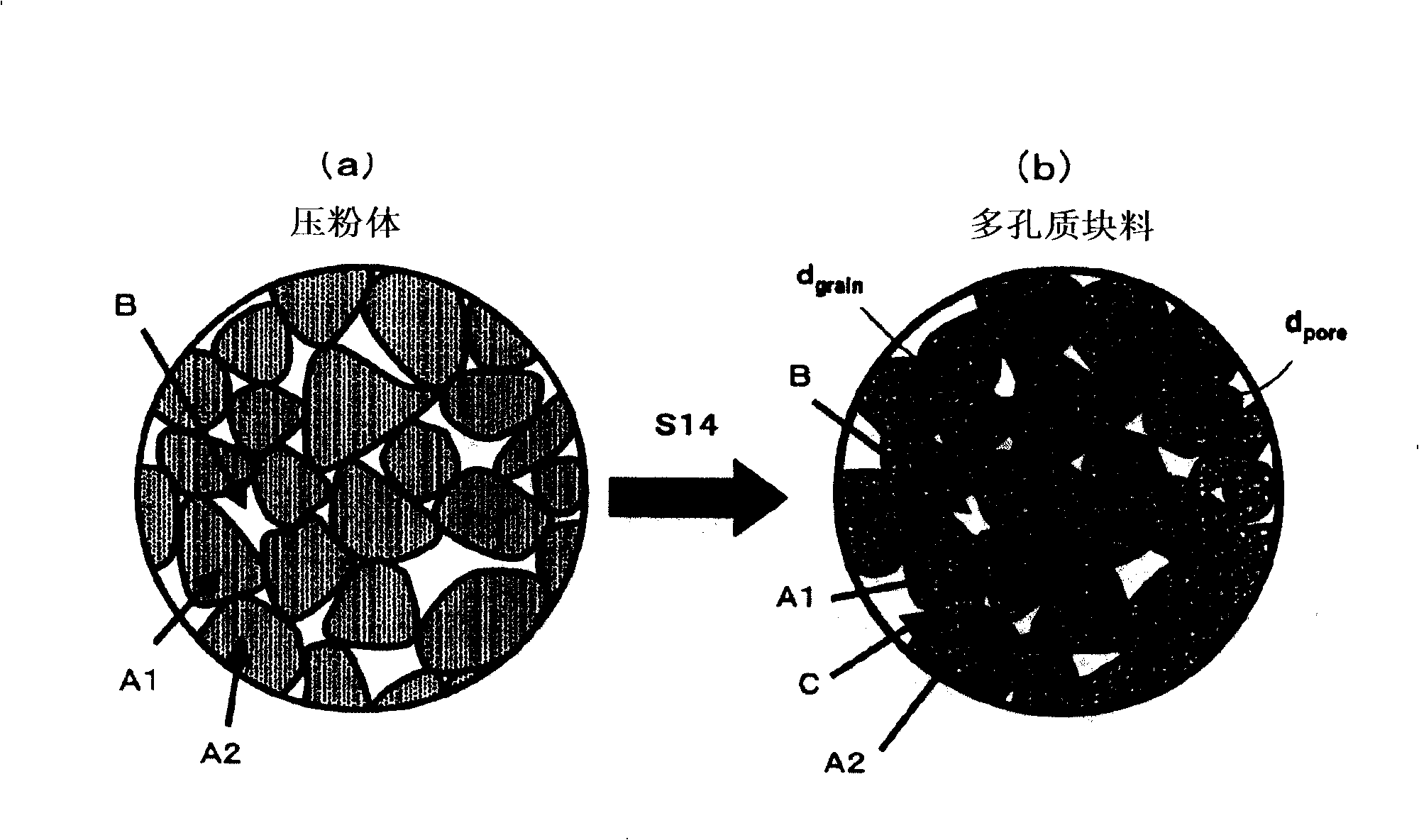

[0113] Hereinafter, preferred embodiments of the method for producing the R—Fe—B based porous magnet of the present invention will be described in detail.

[0115] First, an ingot of an R-T-Q-based alloy (starting alloy) having an R-Fe-B phase as a hard magnetic phase is prepared. Here, "R" is a rare earth element including Nd and / or Pr at 50 atomic % (at%) or more. The rare earth element R in this specification also includes yttrium (Y). "T" is at least one transition metal element selected from Fe, Co, and Ni, and is a transition metal element including 50% or more of Fe. "Q" is B, or a combination of B and a portion of B replaced by C.

[0116] The R-T-Q type alloy (starting alloy) includes Nd with a volume ratio of 50% or more 2 Fe 14 Type B compound phase (hereinafter abbreviated as "R 2 T 14 Q").

[0117] Most of the rare earth element R included in the starting alloy is composed of R 2 T 14 Q, but partly also constituted as R 2 o 3 W...

Embodiment 1

[0224] An alloy (target composition: Nd 13.65 Fe bal co 16 B 6.5 Ga 0.5 Zr 0.09 (atomic %)), a porous rare earth permanent magnet was produced by the production method of the above-mentioned embodiment. The unit of the numerical value in Table 1 is mass %. Hereinafter, the production method of this embodiment will be described.

[0225] [Table 1]

[0226] Alloy

Nd

Pr

Fe

co

B

Ga

Zr

A

29.7

0.1

remnant

14.3

1.06

0.50

0.13

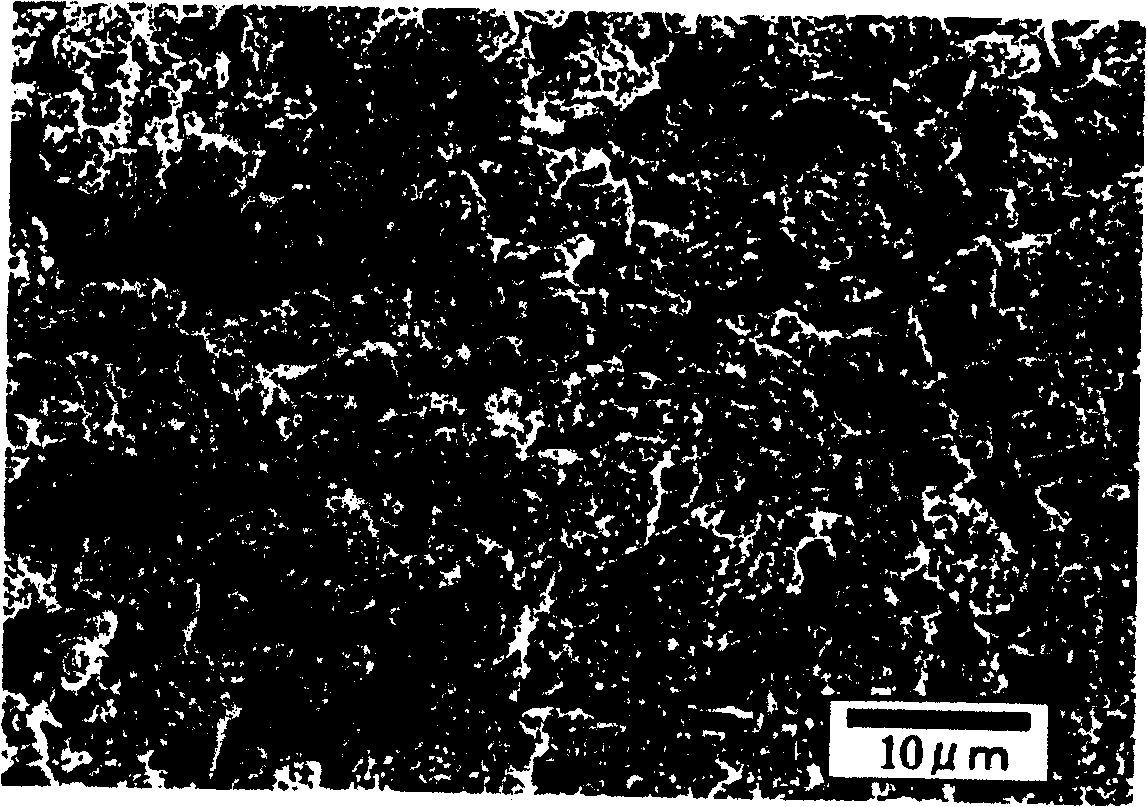

[0227] First, a rapidly solidified alloy having a composition shown in Table 1 was produced by a strip casting method. The obtained rapidly solidified alloy was coarsely pulverized into a powder having a particle diameter of 425 μm or less by a hydrogen storage and collapse method, and then finely pulverized using a jet mill to obtain a fine powder with an average particle diameter of 4.4 μm. Moreover, the "average particle diamet...

Embodiment 2

[0244] Next, the porous magnet of Example 1 was pulverized with a mortar in an argon atmosphere, and classified to produce a powder having a particle diameter of 75 to 300 μm. This powder was put into a cylindrical container, oriented in a magnetic field of 800 kA / m, and fixed with paraffin. After the obtained sample was magnetized in a pulsed magnetic field of 4.8 MA / m, magnetic properties were measured with a vibrating sample type fluxmeter (VSM: device name VSM5 (manufactured by Toei Kogyo Co., Ltd.)). Also, no diamagnetic field correction is performed. The measurement results are shown in Table 3.

[0245] [table 3]

[0246] Alloy

J max

(T)

B r

(T)

h cB

(kA / m)

(BH) max

(kJ / m 3 )

h cJ

(kA / m)

h k

(kA / m)

A

1.16

1.14

595

203

864

338

[0247] J in the table max and B r The true density of the sample is 7.6g / cm 3 obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal particle size | aaaaa | aaaaa |

| Long trail | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com