Embedding slice type composite tool and electrochemic mechanical composite processing device and its processing method

A compound tool and compound processing technology, which is applied in the direction of electric processing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult polishing and large grinding wheel size, and achieve wide processing range, high processing precision and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

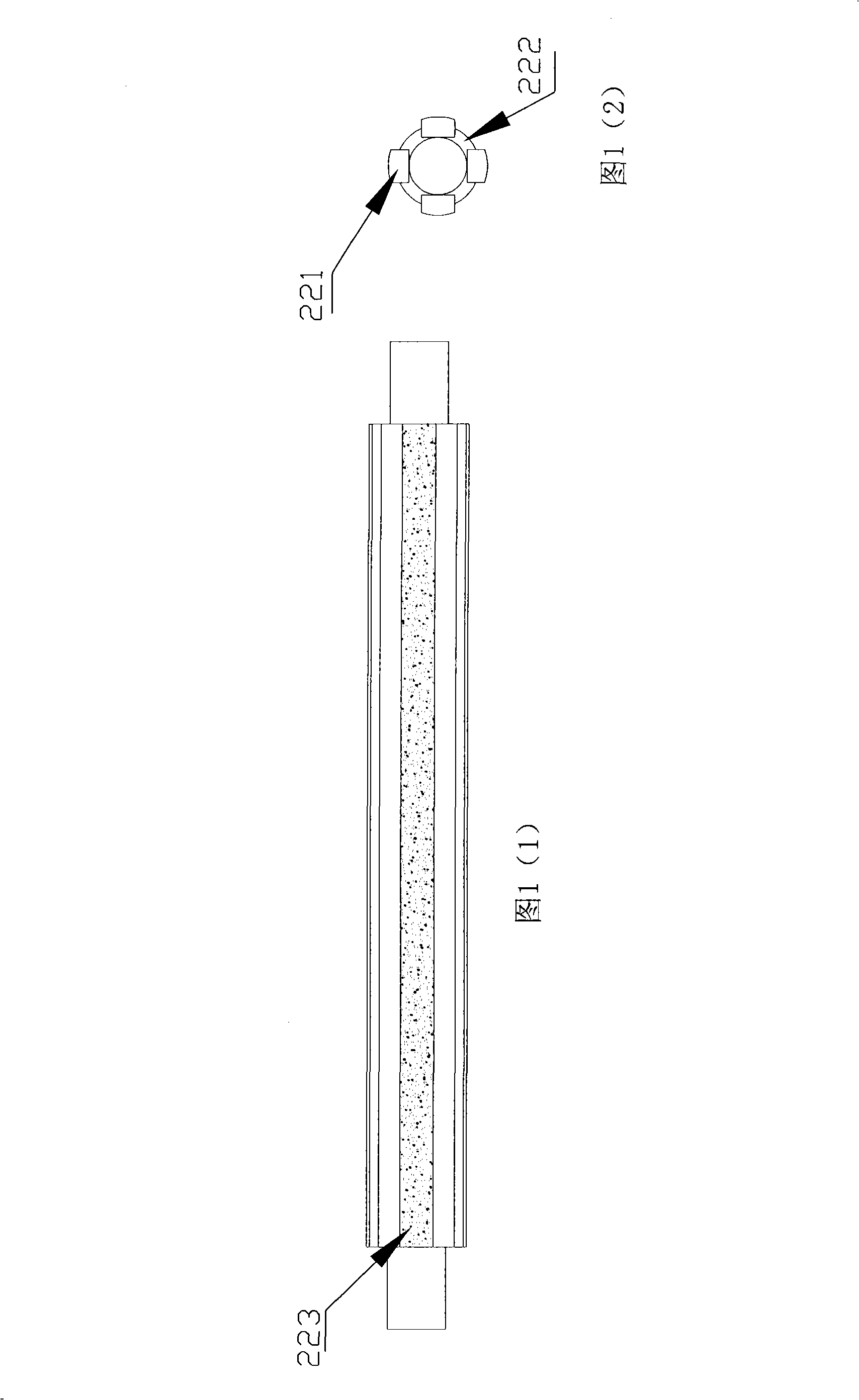

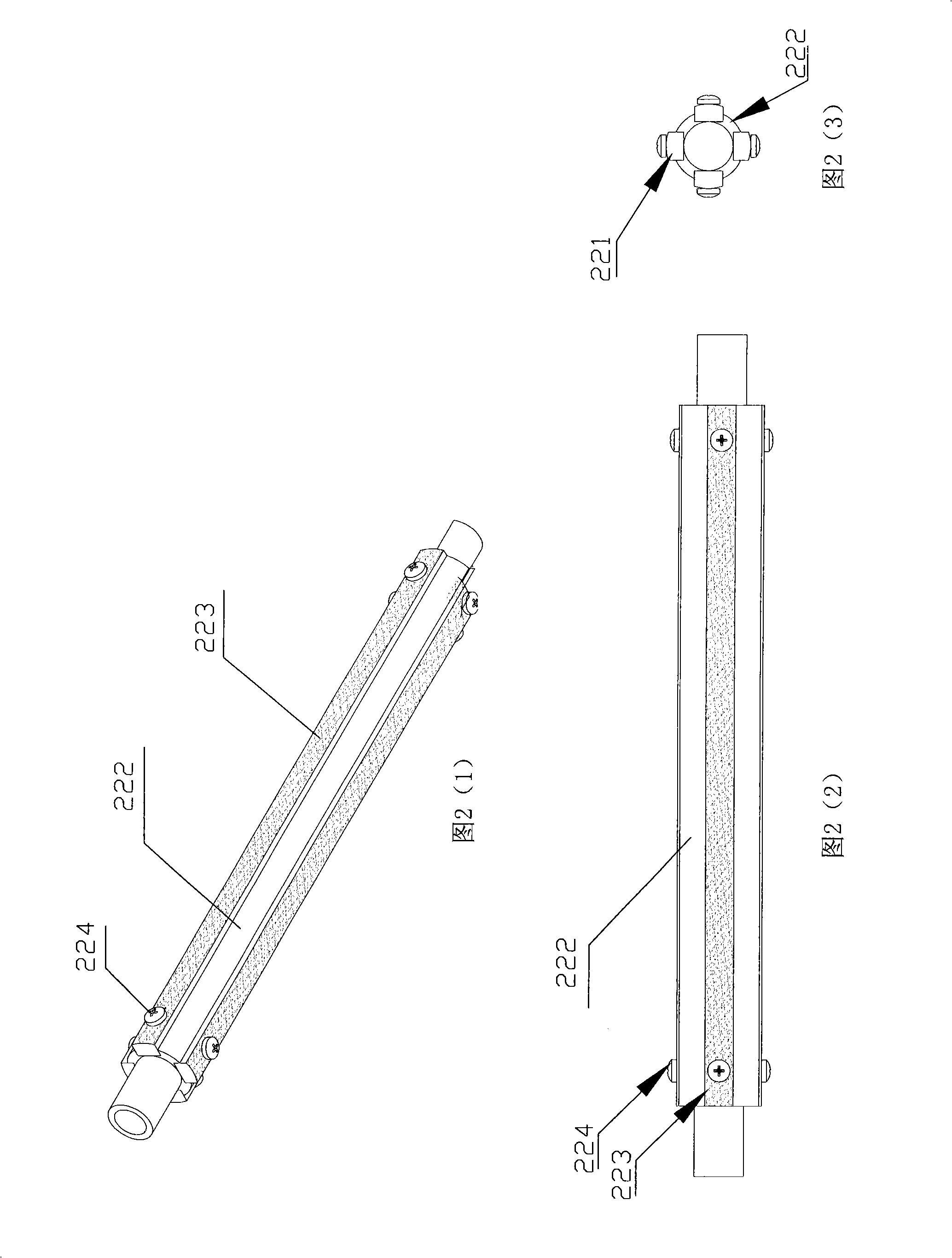

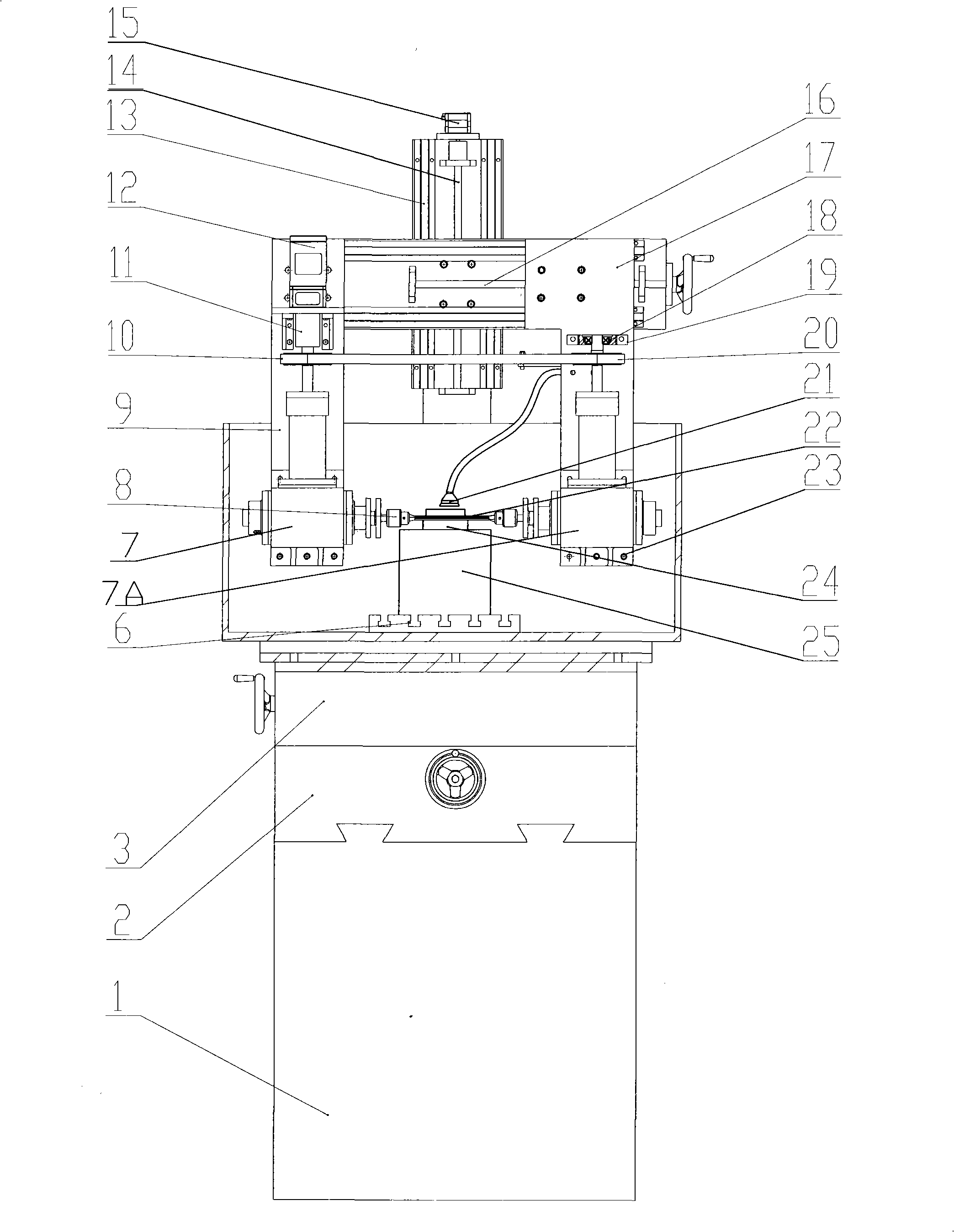

[0040] The structural representation of compound tool 22 of the present invention is shown in Fig. 1 (1), Fig. 1 (2), Fig. 2 (1), Fig. 2 (2), and compound tool 22 of the present invention comprises can remove material, finishing process , scraping the passivation film and guiding the area and direction of the electrolytic machining insert 221 and the substrate 222 as a tool electrode for electrolytic machining, and the insert 221 is fixed on the substrate 222 .

[0041] A layer of abrasive grains 223 is attached to the surface of the insert 221 by electroplating or brazing, or directly sintered into a sand sheet in the form of an insert by powder metallurgy.

[0042] The above-mentioned insert 221 and the matrix 222 are bonded by an insulating resin adhesive, as shown in Figure 1 (1) and Figure 1 (2); when the insert 221 and the matrix 222 are relatively large in size, the insert can The bonding surface of the sheet 221 and the substrate 222 is painted with insulating paint, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com