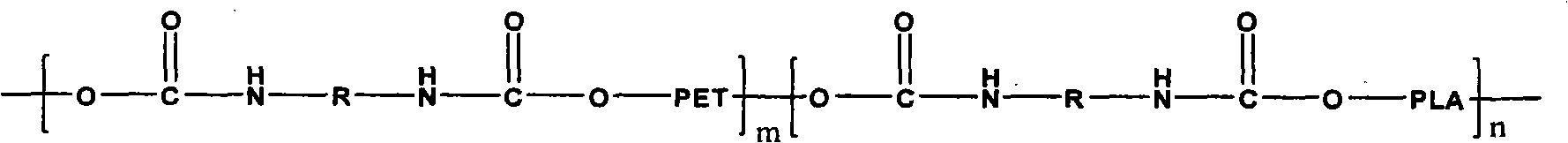

Polylactic acid/polyethylene terephthalate multi-block copolymer, method for preparing same and uses

A technology of polyethylene terephthalate and polyethylene terephthalate, which is applied in the field of polylactic acid/low melting point polyethylene terephthalate multi-block copolymer and its preparation, can solve the problem of Poor reaction reproducibility and controllability, reduced diisocyanate coupling efficiency, difficult control of modified PET structure, etc., to achieve good thermal stability and mechanical processing performance, wide performance range, and increased molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix dimethyl terephthalate and 1,8-octanediol in a molar ratio of 1:3, and 0.2% catalyst zinc acetate in terms of mass percentage of dimethyl terephthalate, at 170°C The transesterification reaction was carried out for 3.5 hours; the obtained octylene terephthalate and ethylene terephthalate were mixed in a molar ratio of 1:1, and then 0.05 % antimony trioxide catalyst, polycondensation reaction at a temperature of 260° C. and a pressure of 250 Pa for 2.4 hours. The resulting product had an intrinsic viscosity of 0.12 dl / g and a melting point of 110°C.

[0034] Mix the obtained low-melting-point PET with the hydroxyl-terminated lactic acid prepolymer with an intrinsic viscosity of 0.06dl / g in a molar ratio of 1:1, heat to melt, and add the low-melting-point PET and lactic acid prepolymerized Add 0.5% coupling agent toluene diisocyanate to the total weight of the product, then react at 140°C for 5 minutes and discharge. The resulting product had an intrinsic viscosity ...

Embodiment 2

[0036] Dimethyl terephthalate and 2,2-dimethyl-1,3-propanediol in a molar ratio of 1:2.5, and 0.08% catalyst acetic acid in terms of mass percent of dimethyl terephthalate Zinc was mixed, transesterified at 175°C for 3 hours, and the resulting 2,2-dimethyl-1,3-propanediol terephthalate was mixed with ethylene terephthalate in a molar ratio of 1:1.22, Then add 0.04% antimony trioxide catalyst based on the total weight of dimethyl terephthalate used in the reaction, and perform polycondensation reaction at a temperature of 265° C. and a pressure of 190 Pa for 3 hours. The resulting product had an intrinsic viscosity of 0.21 dl / g and a melting point of 116°C.

[0037] Mix the obtained low-melting-point PET with the hydroxyl-terminated lactic acid prepolymer with an intrinsic viscosity of 0.09dl / g in a molar ratio of 1:1, heat up to melt, and add the low-melting-point PET and lactic acid prepolymerized under the protection of nitrogen. 1.8% of the total weight of the coupling age...

Embodiment 3

[0039] Mix dimethyl terephthalate and 1,6-hexanediol in a molar ratio of 1:5, and 0.5% catalyst zinc acetate in terms of mass percentage of dimethyl terephthalate, and mix them at 180° C. Under the transesterification reaction for 4.5h, the resulting hexanediol terephthalate and ethylene terephthalate were mixed in a molar ratio of 1:1, and then 0.1 % antimony trioxide catalyst, polycondensation reaction at a temperature of 270° C. and a pressure of 70 Pa for 4.5 hours. The resulting product had an intrinsic viscosity of 0.46 dl / g and a melting point of 121°C.

[0040] After mixing the obtained low-melting-point PET and the hydroxyl-terminated lactic acid prepolymer with an intrinsic viscosity of 0.13dl / g in a molar ratio of 1:9, heat up to melt, and add the low-melting-point PET and lactic acid prepolymerization amount under the protection of nitrogen. 9.7% of the total weight of the coupling agent toluene diisocyanate, and then reacted at 128 ° C for 90 minutes to discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com