Method for preparing urethane elastomer

A polyurethane elastomer and polyester diol technology, which is applied in the field of polyurethane elastomer preparation, can solve the problems of polyurethane performance limitations and inability to meet various needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

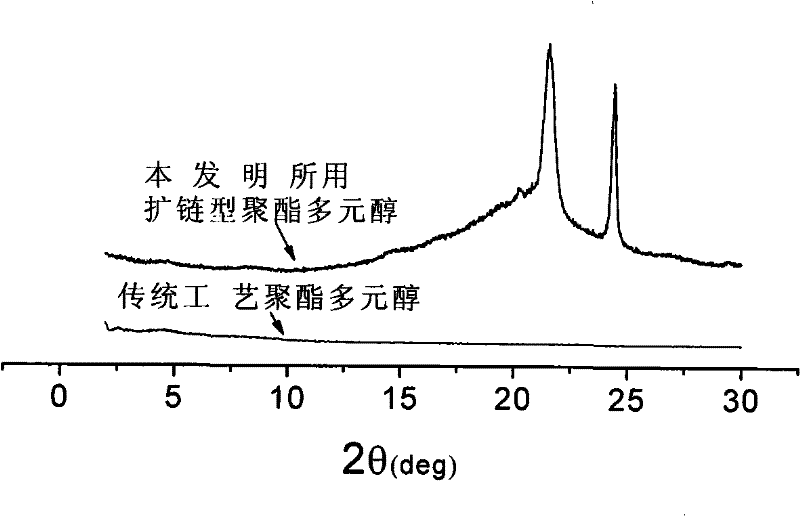

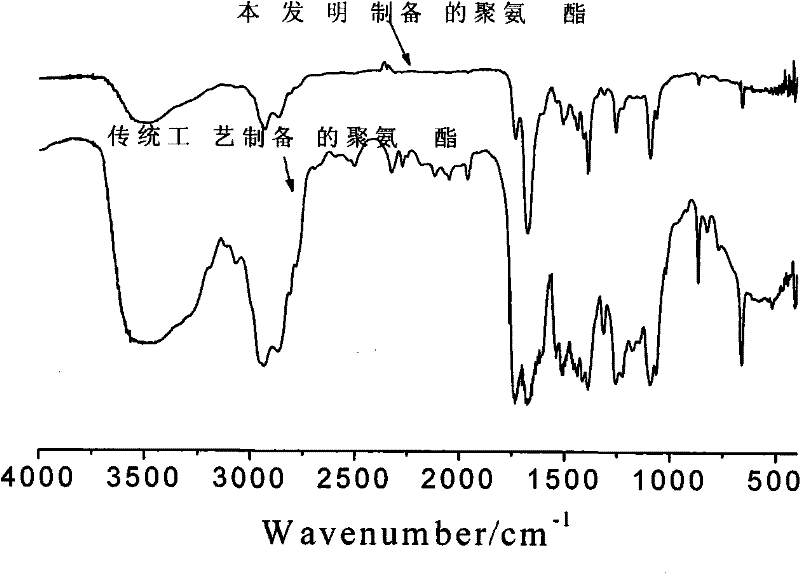

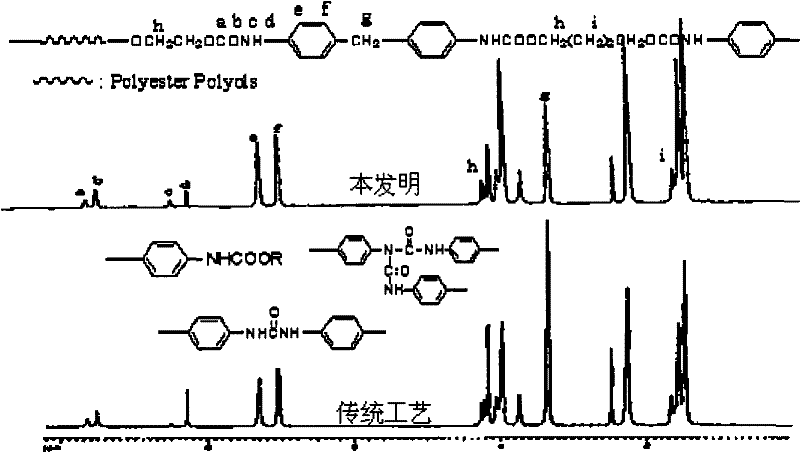

[0015] Put 100 parts of ethylene glycol (EG) and 247 parts of adipic acid (AA) into the reaction bottle, raise the temperature to 225°C, adjust the stirring speed, strictly control the distillation temperature at 102±3°C on the way, and keep it warm for 1 hour after reaching the temperature. If the distillation temperature drops to 80°C, reduce the pressure to 0.8MPa and continue the reaction for half an hour, measure the acid value, if the acid value is 112±3mgKOH / g, lower the temperature to 160°C, put in the measured 1,4-butanediol, Raise the temperature to 230°C and react for 1 hour, add the catalyst n-tetrabutyl titanate and reduce the pressure to -1MPa to react for half an hour, measure the acid value, if the acid value is figure 1 As shown, its comparison with the original one is shown in the table below.

[0016]

[0017] Use 100 parts of the above-mentioned self-made chain-extending polyester polyol, 4.5 parts of chain extender 1,4-butanediol (BDO), and 3.1 parts of ...

Embodiment 2

[0020] Replace ethylene glycol with diethylene glycol (DEG), put 170 parts of diethylene glycol, and 247 parts of adipic acid (AA) into the reaction bottle, raise the temperature to 230°C, adjust the stirring speed, and strictly control the distillation temperature at 102±3°C on the way . After the temperature is reached, keep the reaction for 1 hour. If the distillation temperature drops to 80°C, reduce the pressure to 0.8MPa and continue the reaction for half an hour. Measure the acid value. If the acid value is 112±3mgKOH / g. Lower the temperature to 160°C, put in the measured 1,4-butanediol, raise the temperature to 230°C and react for 1 hour, add the catalyst n-tetrabutyl titanate and reduce the pressure to -1MPa to react for half an hour, measure its acid value, if the acid value is < 1mgKOH / g, measure its hydroxyl value, if the hydroxyl value is 37±3mgKOH / g, discharge. If the hydroxyl value has not reached, continue to discharge alcohol until the chain-extended polyeste...

Embodiment 3

[0023] Replace ethylene glycol diethylene glycol (DEG) with diethylene glycol (DEG), put 170 parts of diethylene glycol (DEG) and 247 parts of adipic acid (AA) into the reaction bottle, raise the temperature to 228 ° C, adjust the stirring speed, During the process, the distillation temperature was strictly controlled at 102±3°C. After the temperature is reached, keep the reaction for 1 hour. If the distillation temperature drops to 80°C, reduce the pressure to 0.8MPa and continue the reaction for half an hour. Measure the acid value. If the acid value is 112±3mgKOH / g. Cool down to 160°C, put in measured ethylene glycol (EG), heat up to 230°C and react for 1 hour, add catalyst n-tetrabutyl titanate and depressurize to -1MPa, react for half an hour, measure its acid value, if the acid value is <1mgKOH / g, measure its hydroxyl value, if the hydroxyl value is 37±3mgKOH / g, discharge. If the hydroxyl value has not reached, continue to discharge alcohol until the chain-extended pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com