Ordered porous magnetic hydroxylapatite material, preparation method thereof and applications

A hydroxyapatite and magnetic technology, applied in chemical instruments and methods, phosphorus compounds, medical science, etc., can solve the problems of uneven distribution of mesopore structure, uneven drug release, and non-porous structure, etc., and achieve a pore structure Orderly, good biocompatibility and bioactivity, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

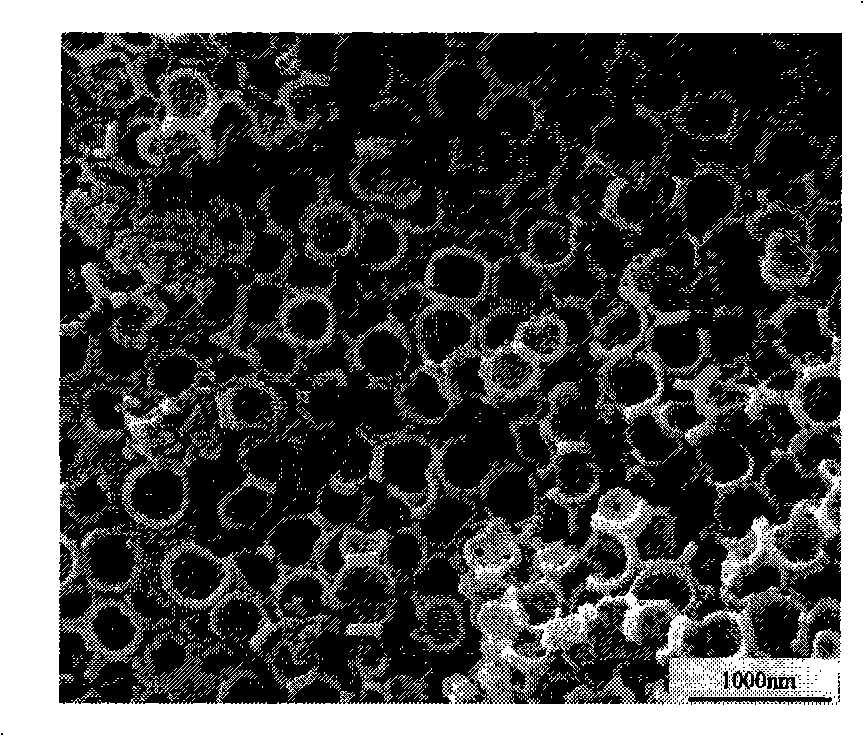

Embodiment 1

[0021] (1) Take monodisperse SiO with a particle size of about 500nm 2 Colloidal particles, dispersed in absolute ethanol, made into a 1wt% suspension, and SiO can be obtained after standing for 14 days 2 Ordered template; after mixing 11.753g of calcium nitrate tetrahydrate, 8.5ml of water, 3.4ml of trimethyl phosphate and 7ml of ethanol, the pH value of the system was adjusted to 9 with ammonia water, and then stirred at 80°C for 48 hours to obtain Hydroxyapatite sol, add the sol dropwise to SiO 2 In the ordered template, after drying at 50°C for 24 hours, it was calcined in a temperature-controlled furnace at 600°C for 2 hours, and finally soaked in 3.3mol / L sodium hydroxide solution for 3 days to prepare ordered porous hydroxyapatite material , The pore size distribution is around 400nm.

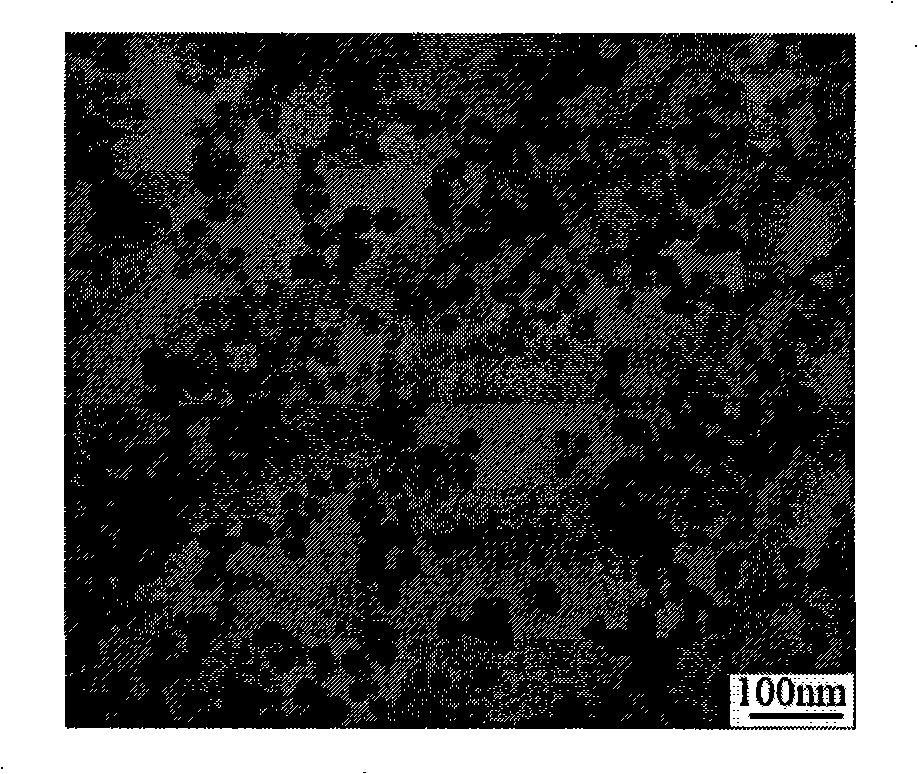

[0022] (2) Under the condition of argon protection, add 1.5g of ferric oxide into a 500ml three-necked bottle, add 100ml of deionized water, ultrasonically disperse for 20min, stir at ...

Embodiment 2

[0025] (1) Take monodisperse SiO with a particle size of about 500nm 2 Colloidal particles, dispersed in absolute ethanol, made into a 1wt% suspension, and SiO can be obtained after standing for 14 days 2 Ordered template; after mixing 11.753g of calcium nitrate tetrahydrate, 8.5ml of water, 3.4ml of trimethyl phosphate and 7ml of ethanol, the pH value of the system was adjusted to 9 with ammonia water, and then stirred at 80°C for 48 hours to obtain Hydroxyapatite sol, add the sol dropwise to SiO 2 In the ordered template, after drying at 50°C for 24 hours, it was calcined in a temperature-controlled furnace at 600°C for 2 hours, and finally soaked in 3.3mol / L sodium hydroxide solution for 3 days to prepare ordered porous hydroxyapatite material , The pore size distribution is around 400nm.

[0026](2) Under the condition of argon protection, add 1.5g of ferric oxide into a 500ml three-necked bottle, add 100ml of deionized water, ultrasonically disperse for 20min, stir at a...

Embodiment 3

[0029] (1) Take monodisperse SiO with a particle size of about 500nm 2 Colloidal particles, dispersed in absolute ethanol, made into a 0.5wt% suspension, and SiO can be obtained after standing for 14 days 2 Ordered template; after mixing 11.753g of calcium nitrate tetrahydrate, 8.5ml of water, 3.4ml of trimethyl phosphate and 7ml of ethanol, the pH value of the system was adjusted to 9 with ammonia water, and then stirred at 80°C for 48 hours to obtain Hydroxyapatite sol, add the sol dropwise to SiO 2 In the ordered template, after drying at 50°C for 24 hours, it was calcined in a temperature-controlled furnace at 600°C for 2 hours, and finally soaked in 3.3mol / L sodium hydroxide solution for 3 days to prepare ordered porous hydroxyapatite material , The pore size distribution is around 400nm.

[0030] (2) Under the condition of argon protection, add 1.5g of ferric oxide into a 500ml three-necked bottle, add 100ml of deionized water, ultrasonically disperse for 20min, stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com