Bridge structural steel plate and producing method thereof

A technology of bridge structure and production method, applied in the field of high-performance Q420qE steel and its production, can solve the problems of low strength level, shortened service life of components, bearing weight limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

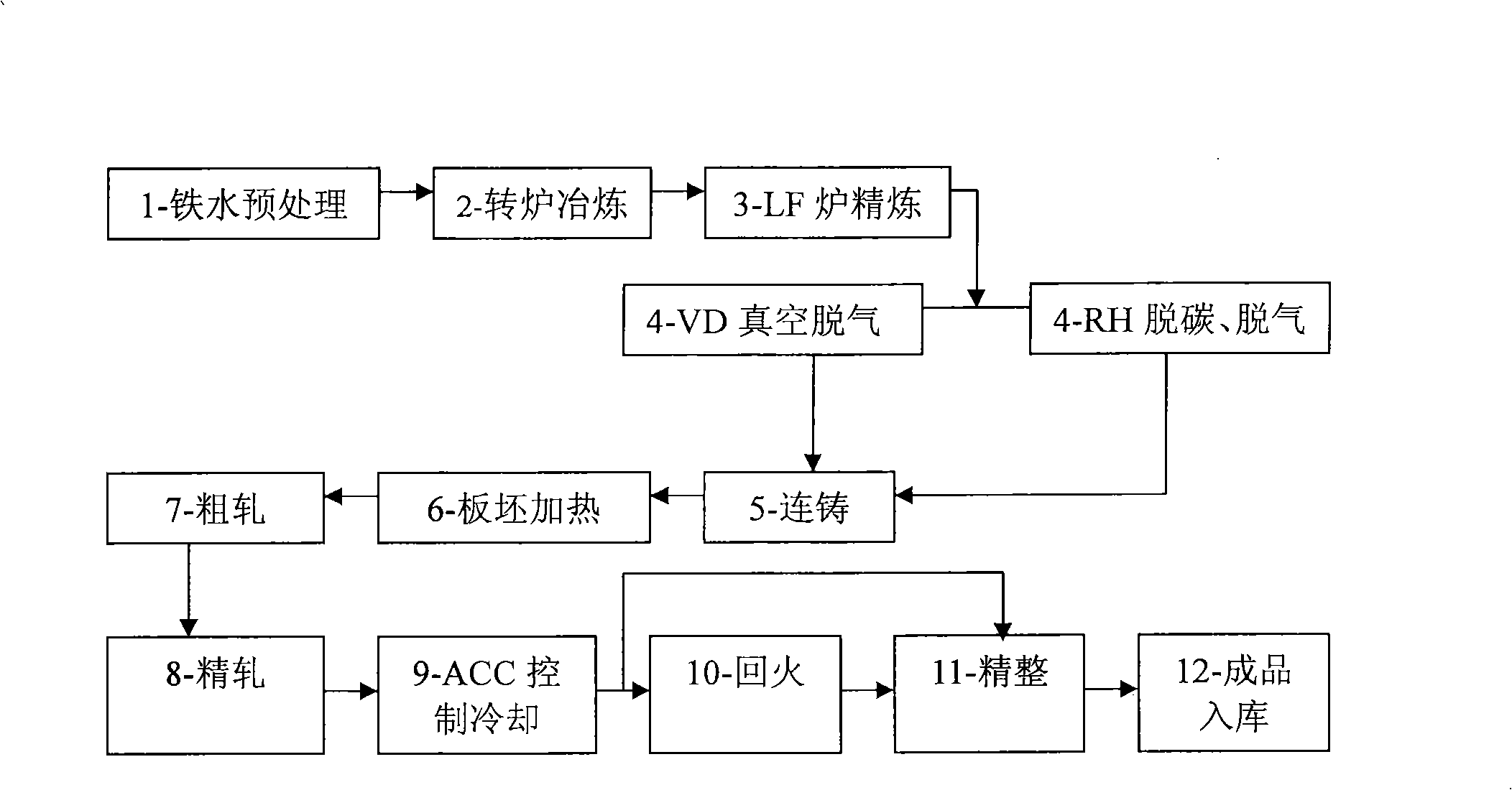

Method used

Image

Examples

Embodiment example 1

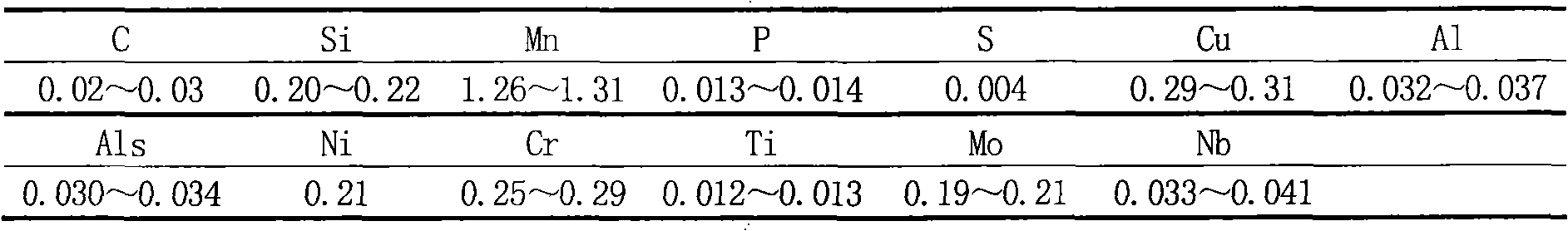

[0032] Billets with the chemical composition in Table 2 were used for rolling.

[0033] The chemical composition of table 2 embodiment 1

[0034]

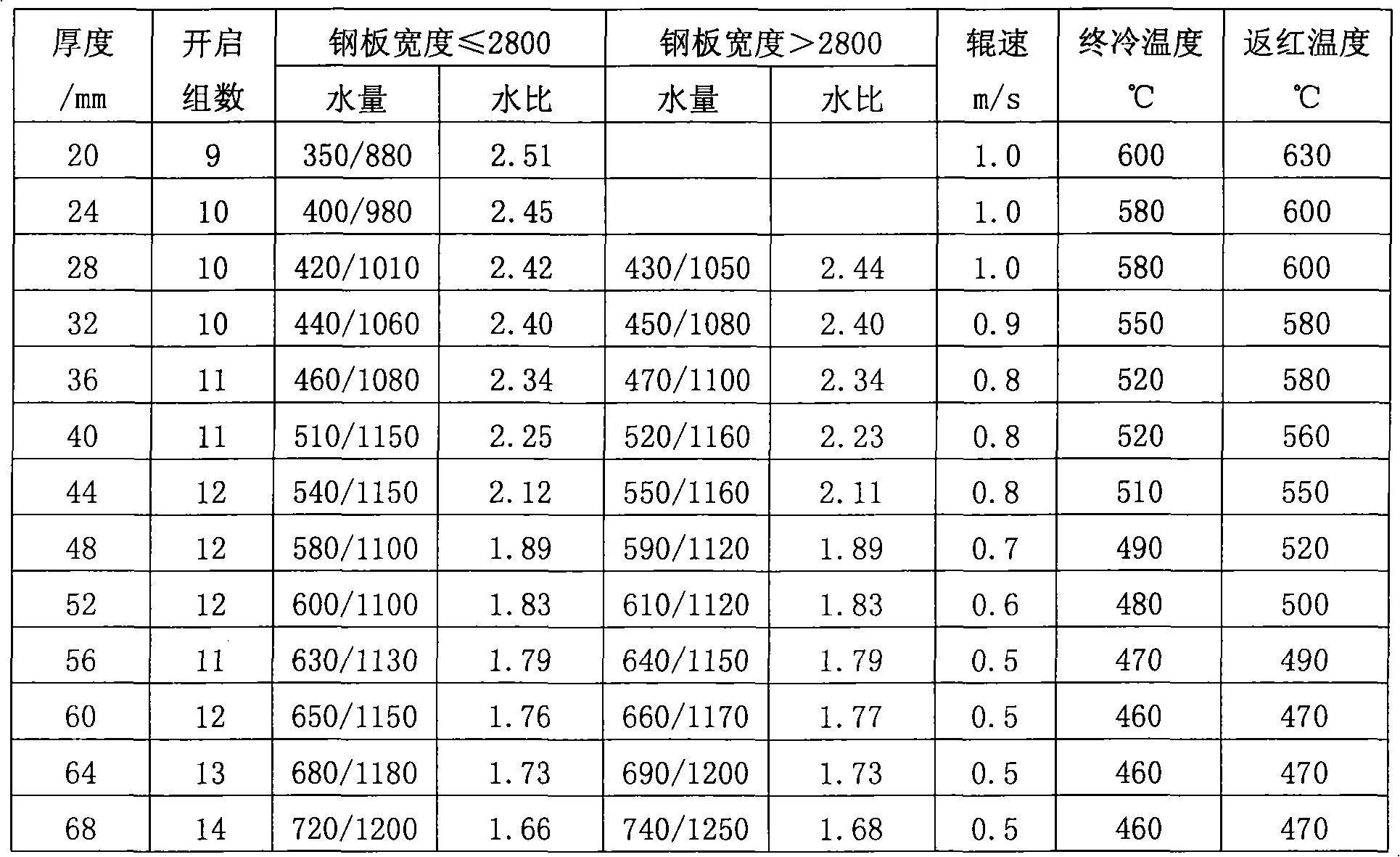

[0035] The heating temperature of the heating furnace is between 1175 and 1207°C; the starting temperature of rough rolling is ≥1020°C, the reduction rate of a single pass is required to be ≥12%, and the thickness of the intermediate billet is 170mm; Reduction rate ≥ 45%; start rolling temperature ≤ 880°C, final rolling temperature ≤ 850°C in the second stage of finishing rolling, cumulative reduction in the last three passes ≥ 34.5%; ACC cooling rate 10°C / S, final cooling temperature 500~ 560°C; tempering temperature 580-600°C, furnace time (min) = plate thickness × 1min / mm+50min.

[0036] The high-performance bridge structural steel plate Q420qE produced by the above process has relatively fine bainite and a small amount of ferrite structure, the grain size is above 10 grades, and the grain size difference is within 2.0 grade...

Embodiment example 2

[0038] Billets with the chemical composition in Table 3 were used for rolling.

Embodiment 2

[0039] Table 3 Example 2 Chemical Components

[0040]

[0041] The heating temperature of the heating furnace is between 1180 and 1240°C; the starting temperature of rough rolling is ≥1000°C, the final rolling temperature is >950°C, the reduction in a single pass is required to be ≥15%, and the thickness of the intermediate billet is 140mm; the starting temperature of finishing rolling is 880°C ~920℃, cumulative rolling reduction ≥ 50%; starting temperature of finish rolling II stage ≤ 880℃, cumulative rolling reduction of the last three passes ≥ 45%, final rolling temperature 814~833℃, ACC cooling rate 10~15 ℃ / S, final cooling temperature 280~420℃; tempering temperature 550℃, time in furnace (min)=plate thickness×1min / mm+50min.

[0042] The high-performance bridge structural steel plate Q420qE produced by the above process has a fine and uniform bainite structure, the grain size is controlled at 11-12 grades, the grain size difference of the structure is controlled within ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Low temperature impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com