Preparation method of biology cellulose composite membrane face-mask material

A bio-cellulose, composite membrane technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of mask performance impact, poor water-holding performance, inconvenient use, etc., to achieve strong moisturizing, high yield The effect of improving and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

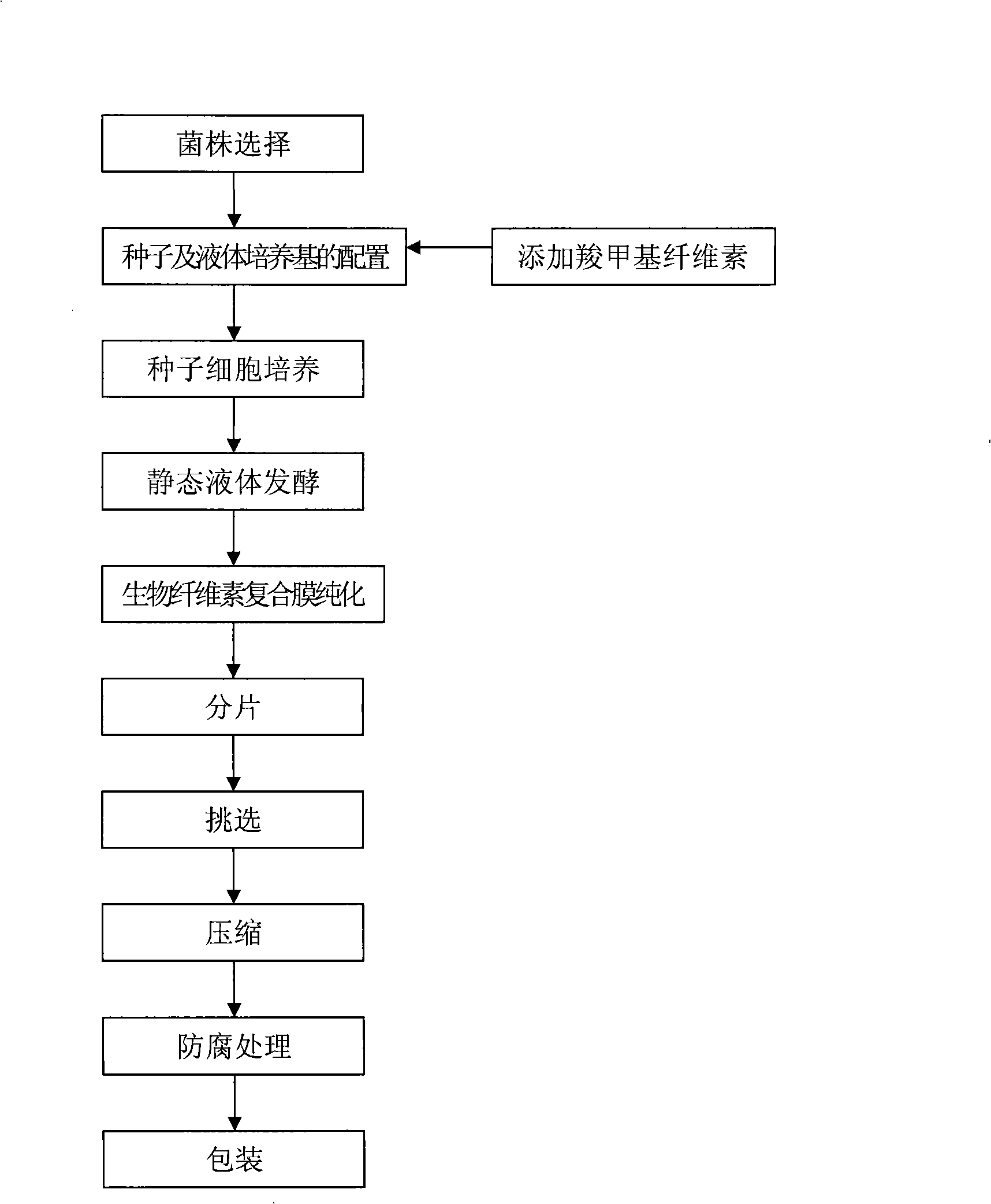

Method used

Image

Examples

Embodiment 1

[0037] (1) Selection of strains: select Gluconacetobacter xylinum CGMCC No.1.1812;

[0038] (2) Preparation of carboxymethyl cellulose seeds and liquid culture medium: In terms of weight percentage, the formula is composed as follows:

[0039] A: Glucose 2%

[0041] C: Tryptone 0.5%

[0042] D: Na 2 HPO 4 0.5%

[0043] E: Citric acid 0.2%

[0044] F: calcium carbonate 2%

[0045] The balance is water;

[0046] Add 0.2g / L carboxymethyl cellulose to the seed medium or liquid medium, then adjust the pH of the medium to 5, sterilize at 121°C for 20 minutes, and cool to 30°C for later use;

[0047] (3) Cultivation of seed cells: Take 1-2 loops of activated slant seeds and insert them into a liquid culture medium containing carboxymethyl cellulose under aseptic operating conditions, at 28°C on a shaker with a rotation speed of 140r / min Shake culture for 24 hours to obtain seed culture solution;

[0048] (4) Production of bio-cellulose composit...

Embodiment 2

[0051] (1) Selection of strains: select Gluconacetobacter xylinum CGMCC No. 1.2378;

[0052] (2) Preparation of carboxymethyl cellulose seeds and liquid culture medium: In terms of weight percentage, the formula is composed as follows:

[0053] A: Fructose 4%

[0055] C: Tryptone 1%

[0056] D: Na 2 HPO4 1%

[0057] E: Citric acid 0.3%

[0058] F: calcium carbonate 3%

[0059] The balance is water;

[0060] Add 0.8g / L of carboxymethylcellulose to the seed medium or liquid medium, then adjust the pH of the medium to 6, sterilize at 121°C for 25 minutes, and cool to 30°C for later use;

[0061] (3) Cultivation of seed cells: Take 1-2 loops of activated slant seeds and put them in a liquid culture medium containing carboxymethyl cellulose under aseptic operation conditions at 32°C on a shaker with a rotation speed of 180r / min Shake culture for 36 hours to obtain seed culture solution;

[0062] (4) Static liquid fermentation to produce bio-cellu...

Embodiment 3

[0065] (1) Selection of strain: select Gluconacetobacter xylinum CGMCC No. 1.1812;

[0066] (2) Preparation of carboxymethyl cellulose seeds and liquid culture medium: In terms of weight percentage, the formula is composed as follows:

[0067] A: Sucrose 3%

[0068] B: Yeast powder 0.8%

[0069] C: Tryptone 0.8%

[0070] D: Na 2 HPO 4 0.8%

[0071] E: Citric acid 0.25%

[0072] F: calcium carbonate 2.5%

[0073] The balance is water;

[0074] Add 0.5g / L of carboxymethylcellulose to the seed medium or liquid medium, then adjust the pH of the medium to 6, sterilize at 121°C for 20 minutes, and cool to 30°C for later use;

[0075] (3) Cultivation of seed cells: Take 1-2 loops of activated slant seeds, insert them into a liquid culture medium containing carboxymethyl cellulose under aseptic operation conditions, and place them on a shaker with a rotation speed of 160r / min at 30°C. Shake culture for 30 hours to obtain seed culture solution;

[0076] (4) Production of bio-ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com