R-Fe-B rare earth sintered magnet and method for producing same

A technology of sintered magnets and manufacturing methods, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve the problems of weakening of magnet characteristics, decrease of magnetic composition ratio of magnet forming body, safety ignition, etc., to achieve suppression reduction, Effect of coercive force improvement and HcJ improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0107] [raw material alloy]

[0108] First, an alloy containing 25% by mass to 40% by mass of the light rare earth element RL, 0.6% to 1.6% by mass of B (boron), and the balance Fe and unavoidable impurities is prepared. A part of B may be replaced with C (carbon), and a part of Fe (less than 50 atomic %) may be replaced with other transition metal elements (such as Co or Ni). According to various purposes, the alloy may also contain about 0.01 to 1.0% by mass of Al, Si, Ti, V, Cr, Mn, Ni, Cu, Zn, Ga, Zr, Nb, Mo, Ag, In, Sn , Hf, Ta, W, Pb and Bi add at least one element M.

[0109] The above-mentioned alloy is suitably produced by rapidly cooling a molten material alloy by, for example, a strip casting method. Next, the production of the rapidly solidified alloy by the strip continuous casting method will be described.

[0110] First, in an argon atmosphere, a raw material alloy having the above composition is melted by high-frequency melting to form a raw material alloy m...

Embodiment approach 2

[0129] In this embodiment, first, a rare earth element containing 25% by mass to 40% by mass is prepared (heavy rare earth element RH is 0.1% by mass to 5.0% by mass, and the rest is light rare earth element RL). , 0.6% by mass to 1.6% by mass of B (boron), and the balance being Fe and unavoidable impurities. A part of B may be substituted with C (carbon), and a part of Fe (less than 50 atomic %) may be substituted with other transition metal elements (such as Co or Ni). According to various purposes, the alloy may also contain about 0.01 to 1.0% by mass of Al, Si, Ti, V, Cr, Mn, Ni, Cu, Zn, Ga, Zr, Nb, Mo, Ag, In, Sn , Hf, Ta, W, Pb and Bi add at least one element M.

[0130] Thus, in this embodiment, 0.1 mass % or more and 5.0 mass % or less of the heavy rare earth element RH are added to a raw material alloy in advance. That is, after preparing the known R-Fe- After the B-series rare earth sintered magnet is diffused by vapor deposition, the heavy rare earth element RH d...

Embodiment approach 3

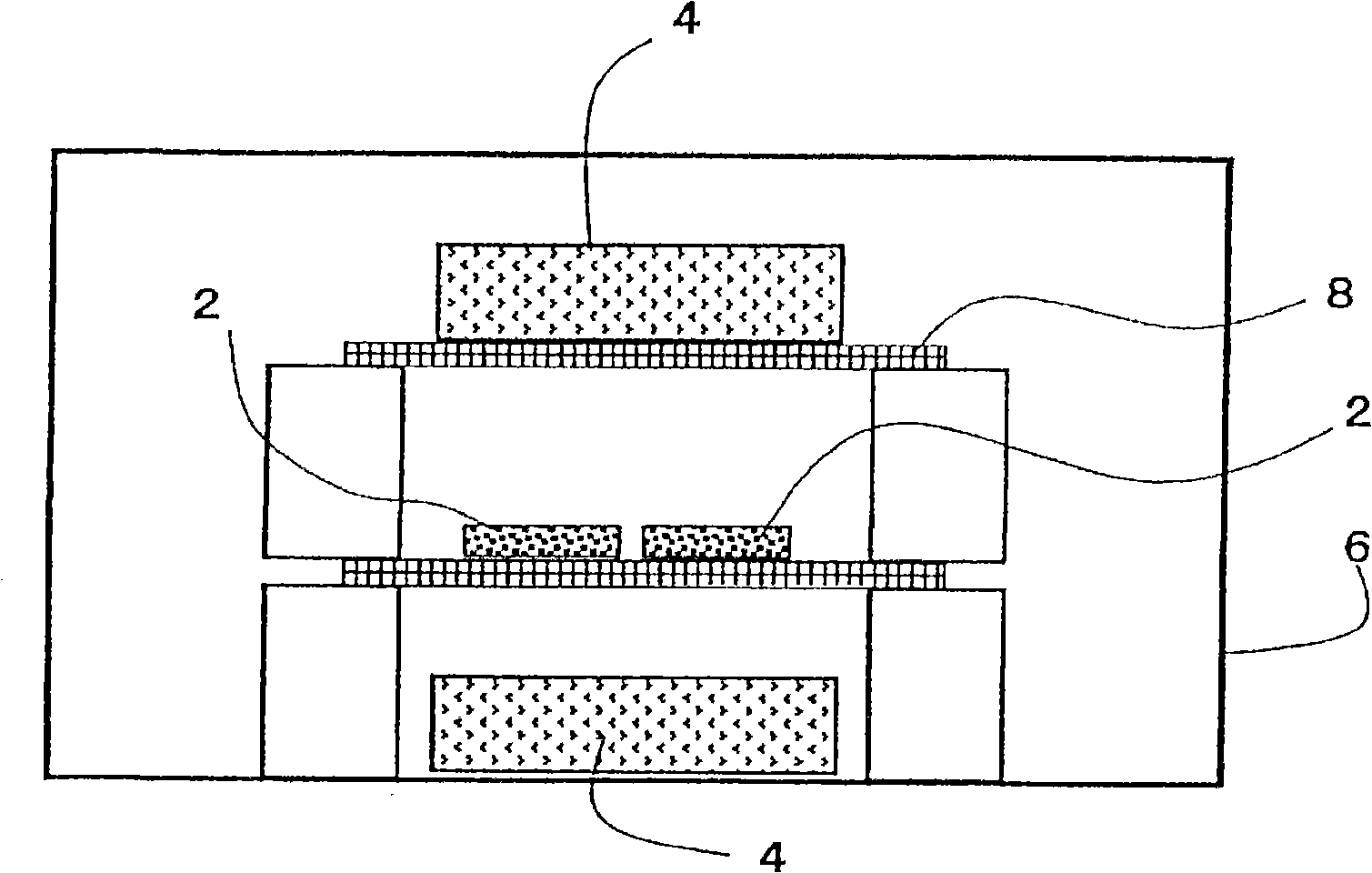

[0136] In the manufacturing method of the R-Fe-B based rare earth sintered magnet of the present embodiment, the sintering step of the R-Fe-B based rare earth sintered magnet powder compact and the step of diffusing the heavy rare earth element RH are performed continuously in the same processing chamber. More specifically, first, a molded body of R-Fe-B rare earth magnet powder containing light rare earth element RL (at least one of Nd and Pr) as the main rare earth element R is mixed with heavy rare earth element The step (A) in which volume bodies of the class element RH (at least one selected from Dy, Ho, and Tb) are arranged oppositely in the processing chamber.

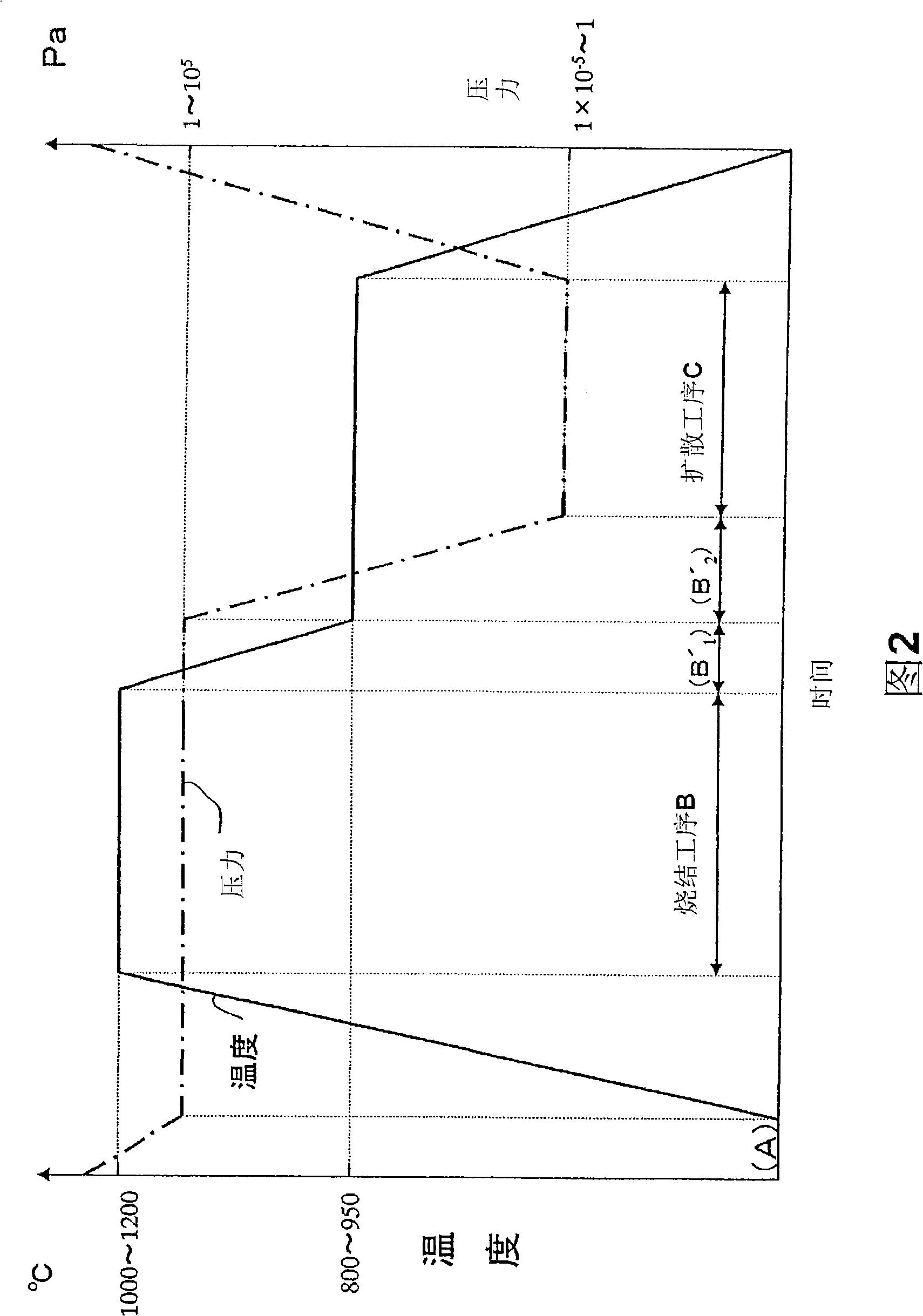

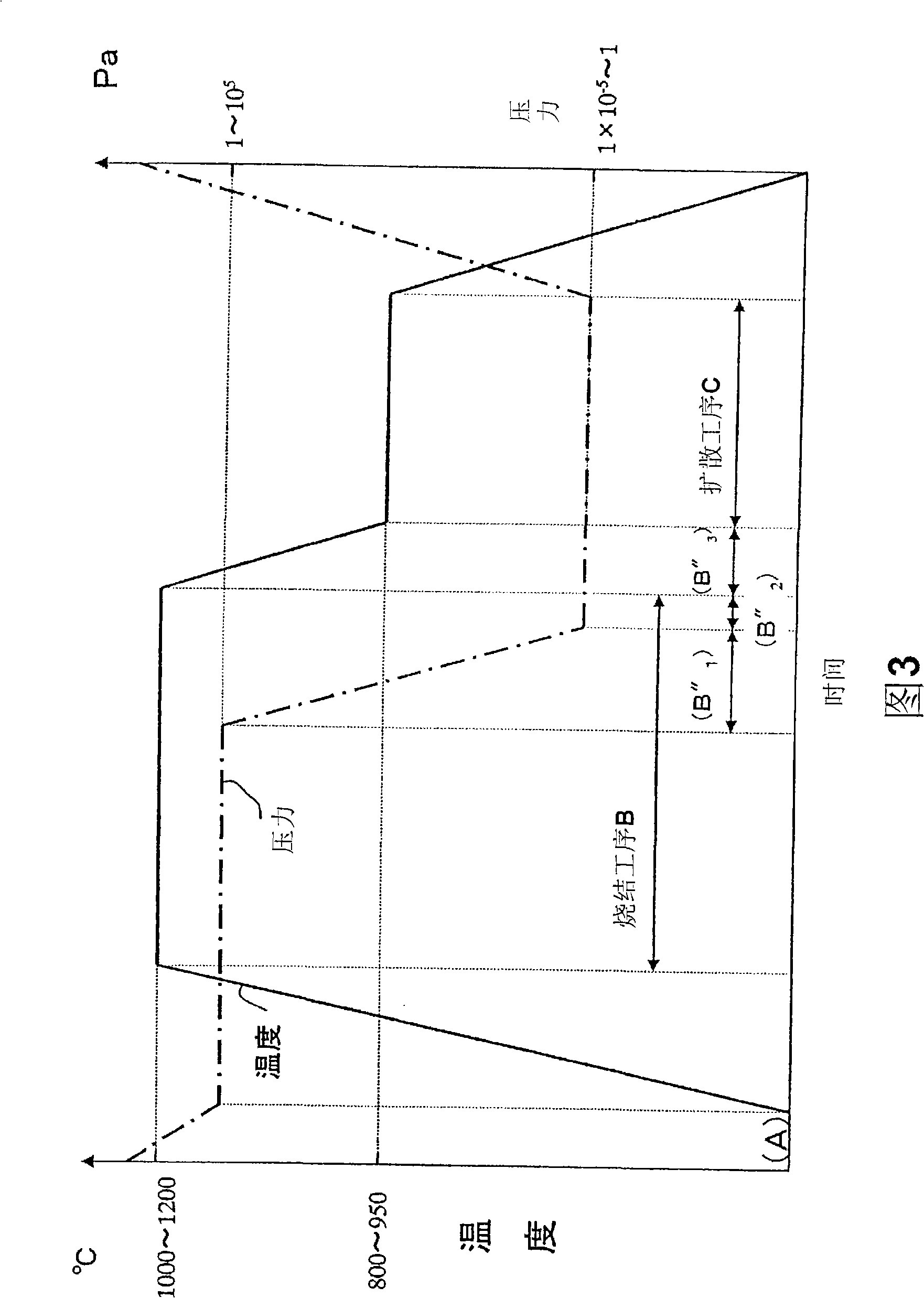

[0137] Then, by performing sintering in the processing chamber, fabricating a 2 Fe 14 Step (B) of R-Fe-B-based rare earth sintered magnet with B-type compound crystal grains as the main phase. Then, the step (C) of supplying the heavy rare earth element RH from the volume body to the R-Fe-B system rare earth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com