Polyolefin microporous membrane

一种微多孔膜、聚烯烃制的技术,应用在膜、膜技术、半透膜分离等方向,能够解决热收缩率比小、电池性能烘烤试验不充分、生产方面不现实等问题,达到热收缩改善、优异电池安全性、优异电池特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125]95% by weight of polyethylene having a homopolymer of Mv of 250,000 and 5% by weight of polypropylene having a homopolymer of Mv of 400,000 were dry-blended using a tank mixer. Add 1 wt% pentaerythritol-tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate] as an antioxidant to the resulting 99 wt% pure polymer mixture, and dry again using a tank mixer Mix to obtain a mixture of polymers and the like. The resulting mixture of polymers and the like was replaced with nitrogen, and then supplied to a twin-screw extruder through a feeder under a nitrogen atmosphere. In addition, liquid paraffin (dynamic viscosity at 37.78°C is 7.59×10 -5 m 2 / s) into the extruder barrel.

[0126] Carry out melt kneading, adjust the feeder and pump, so that the proportion of liquid paraffin in the whole mixture extruded is 55wt%. Melting and kneading conditions were performed at a set temperature of 200° C., a screw rotation speed of 240 rpm, and a discharge rate of 12 kg / h.

[0127] ...

Embodiment 2

[0134] 47.5% by weight of polyethylene having a homopolymer of Mv of 700,000, 47.5% by weight of polyethylene having a homopolymer of Mv of 250,000, and 5% by weight of polypropylene of a homopolymer of Mv of 400,000 were dry-blended using a tank mixer. Add 1 wt% pentaerythritol-tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate] as an antioxidant to the resulting 99 wt% pure polymer mixture, and dry again using a tank mixer Mix to obtain a mixture of polymers and the like. The resulting mixture of polymers and the like was replaced with nitrogen, and then supplied to a twin-screw extruder through a feeder under a nitrogen atmosphere. In addition, liquid paraffin (dynamic viscosity at 37.78°C is 7.59×10 -5 m 2 / s) into the extruder barrel.

[0135] Melt kneading was carried out, and feeders and pumps were adjusted so that the ratio of the amount of liquid paraffin to the entire mixture extruded was 65 wt%. Melting and kneading conditions were performed at a set tempe...

Embodiment 3

[0143] After being extruded onto the cooling roll, casting is carried out by embankment molding, the biaxial stretching temperature is set to 118°C, the heat setting temperature is set to 122°C, and the coiled parent roll is placed in a constant temperature room at 60°C for 6 hours. , except that, it carried out similarly to Example 2, and obtained the microporous film.

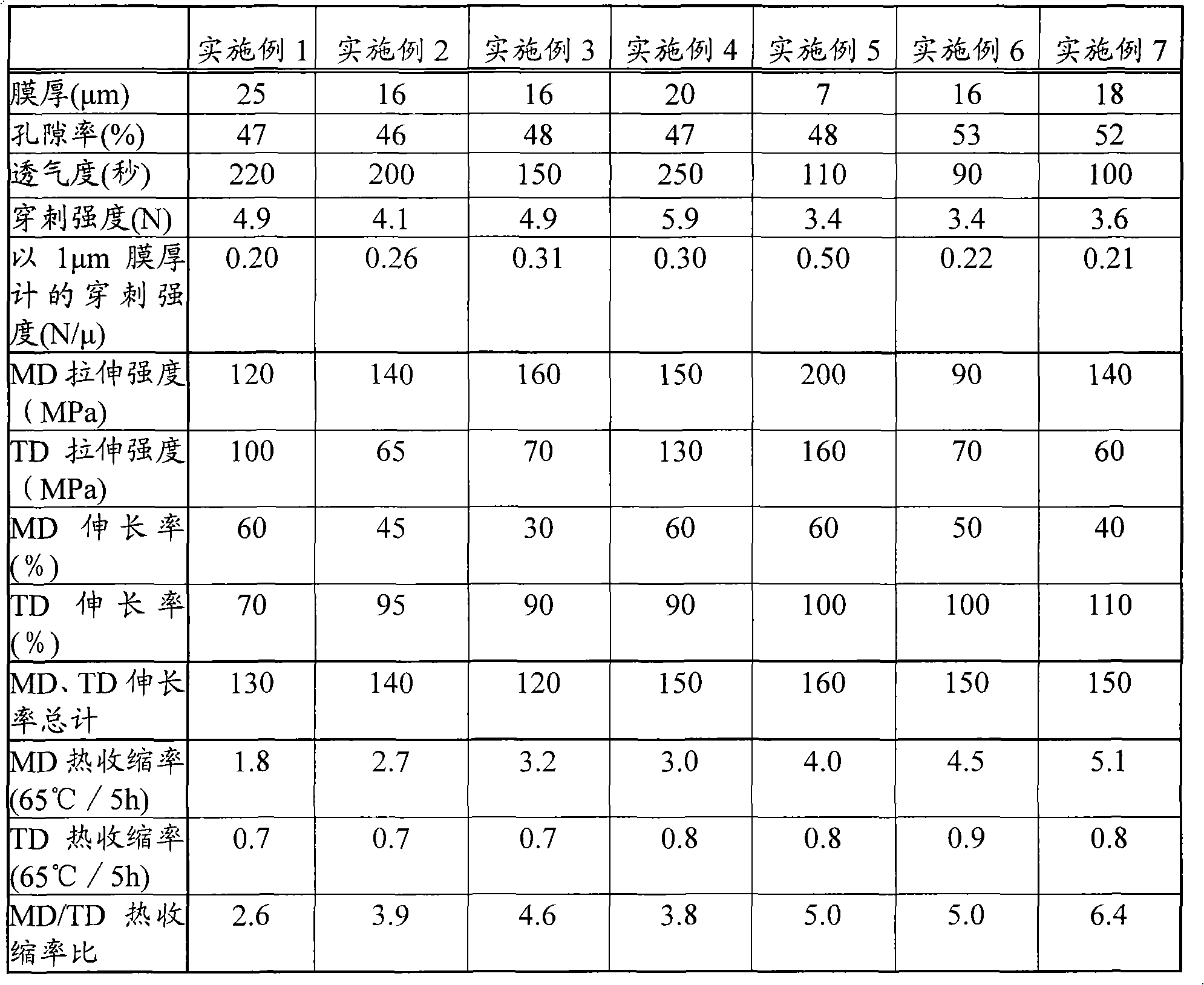

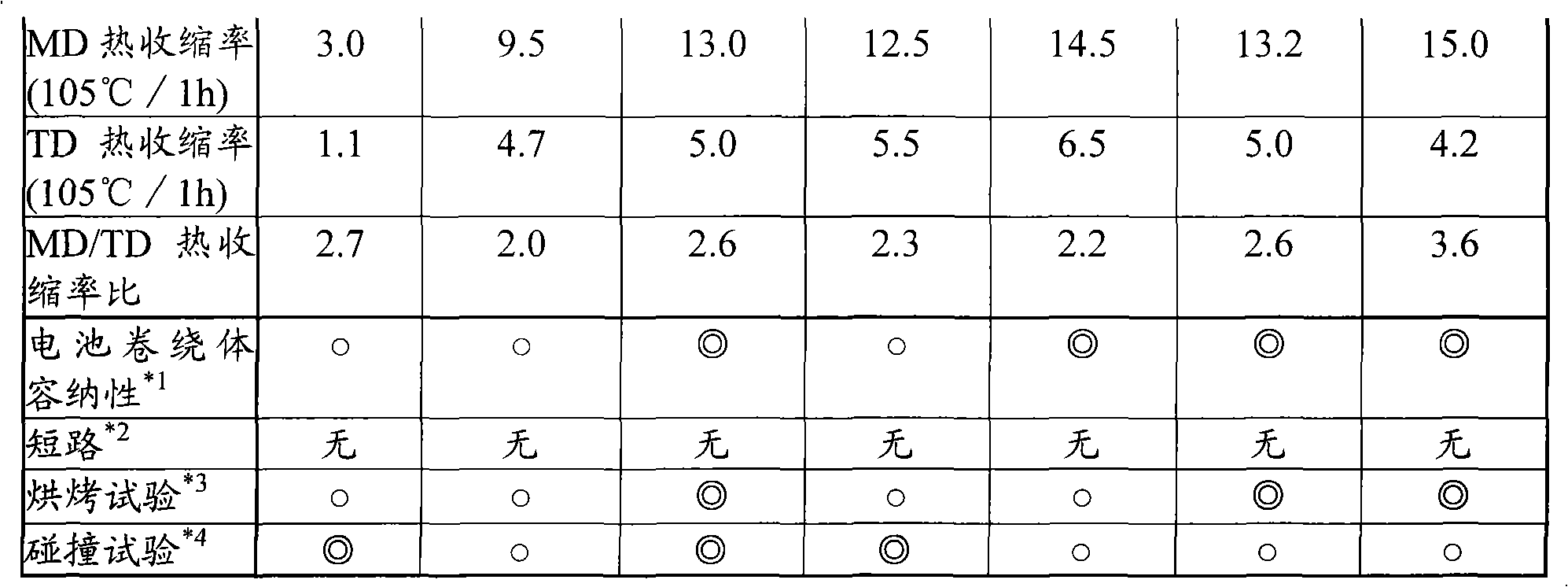

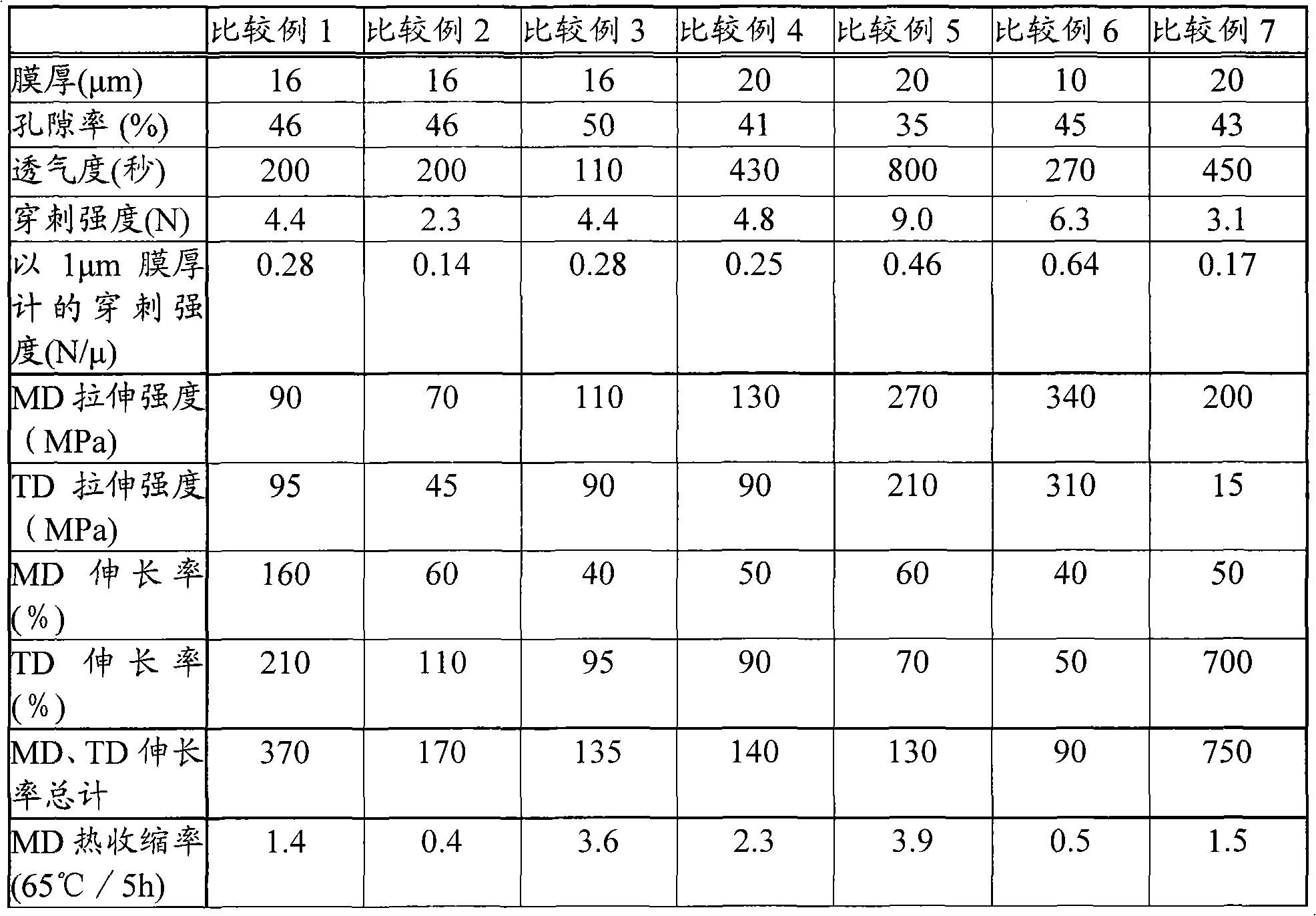

[0144] Table 1 shows the physical properties of the obtained microporous membrane.

[0145] As a result of the battery evaluation, all of them were good results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com