Conductive paste and solar cell

A technology for solar cells and conductive paste, applied in the field of solar cells, can solve the problems of low contact resistance, dependence on contact resistance, and maintain low contact resistance, and achieve the effects of low contact resistance, high energy conversion efficiency, and good battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

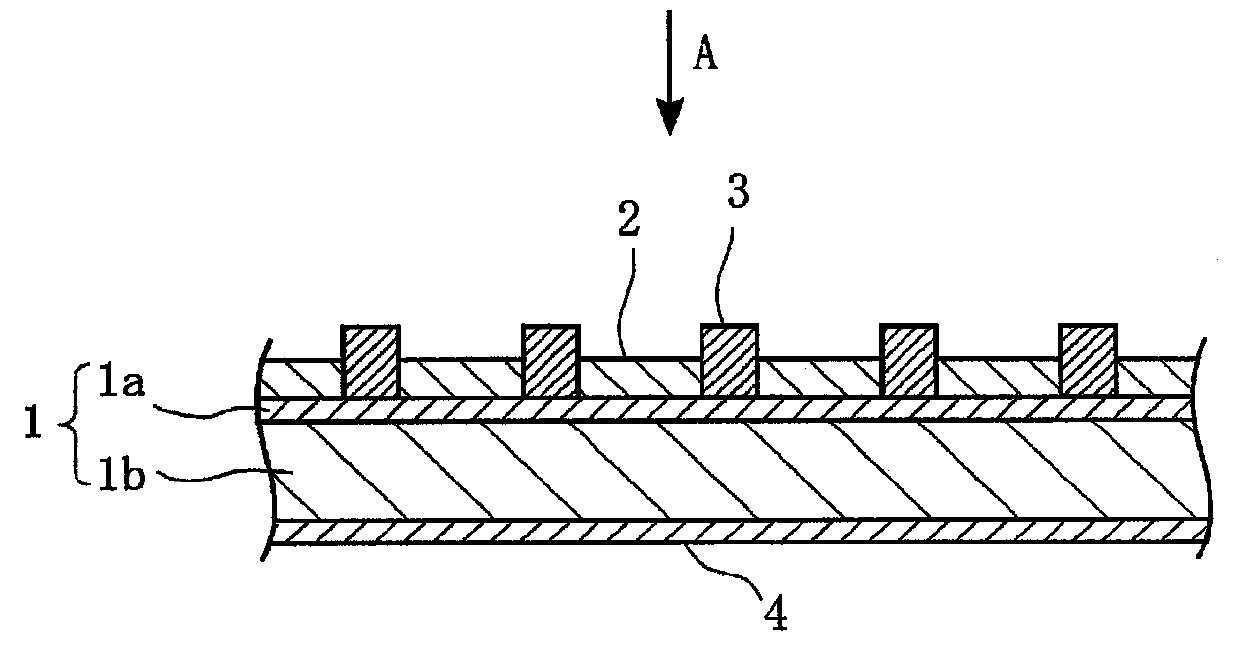

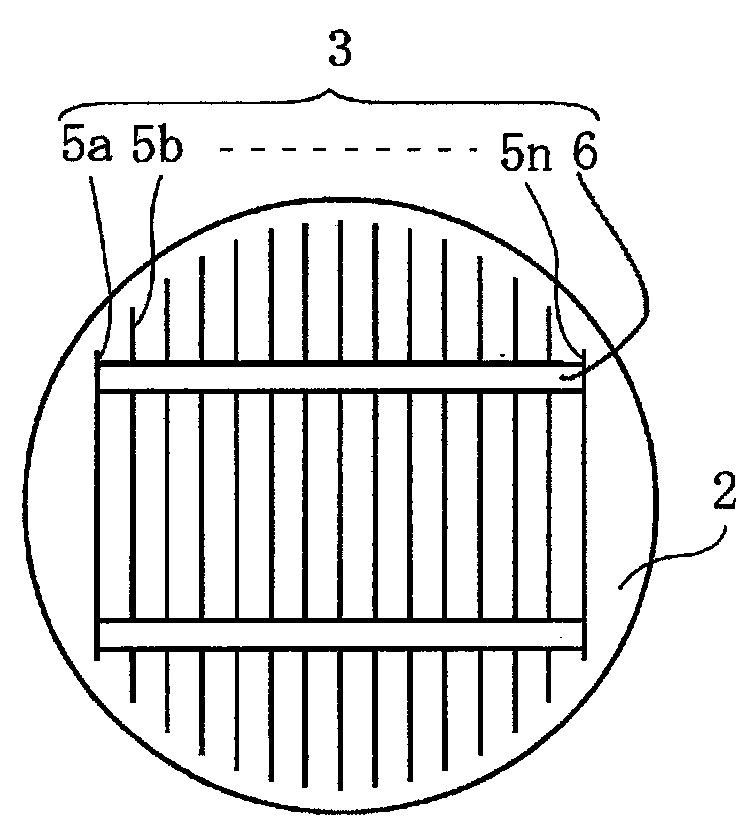

Image

Examples

Embodiment

[0091] 〔Sample making〕

[0092] (Production of conductive paste)

[0093] Prepare TeO as a glass material 2 , ZnO, Bi 2 o 3 , Li 2 O, Na 2 O, K 2 O, MgO, CaO, SrO, BaO, MnO 2 , CuO, Ag 2 O.B 2 o 3 , V 2 o 5 ,P 2 o 5 、TiO 2 , Nb 2 o 5 , Fe 2 o 3 , CoO, NiO, Al 2 o 3 , ZrO 2 、 Ta 2 o 5 , SiO 2 , SnO 2 , Sb 2 o 5 , and MoO 3 . Then, these glass materials were weighed so that it might become the compounding quantity shown in Table 1, and it prepared, and the glass frit of sample numbers 1-26 was produced.

[0094] [Table 1]

[0095]

[0096] In addition, spherical Ag powder having an average particle diameter of 1.6 μm was prepared as the conductive powder.

[0097] Next, ethyl cellulose resin and ester alcohol were mixed so that 10 wt% of ethyl cellulose resin was used as a binder resin and 90 wt% of ester alcohol was used as an organic solvent to prepare an organic vehicle.

[0098] Then, the Ag powder becomes 86.0wt%, and the glass powder beco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com