Refrigeration and heating double-effect air conditioner system using ultrasonic atomization technique

A refrigeration heating and air conditioning system technology, applied in the field of refrigeration heating systems and double-effect air conditioning systems, can solve the problems of heavy weight, complex structure, atmospheric ozone layer destruction, etc., achieve safe and convenient installation, simple mechanical structure, and reduce operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

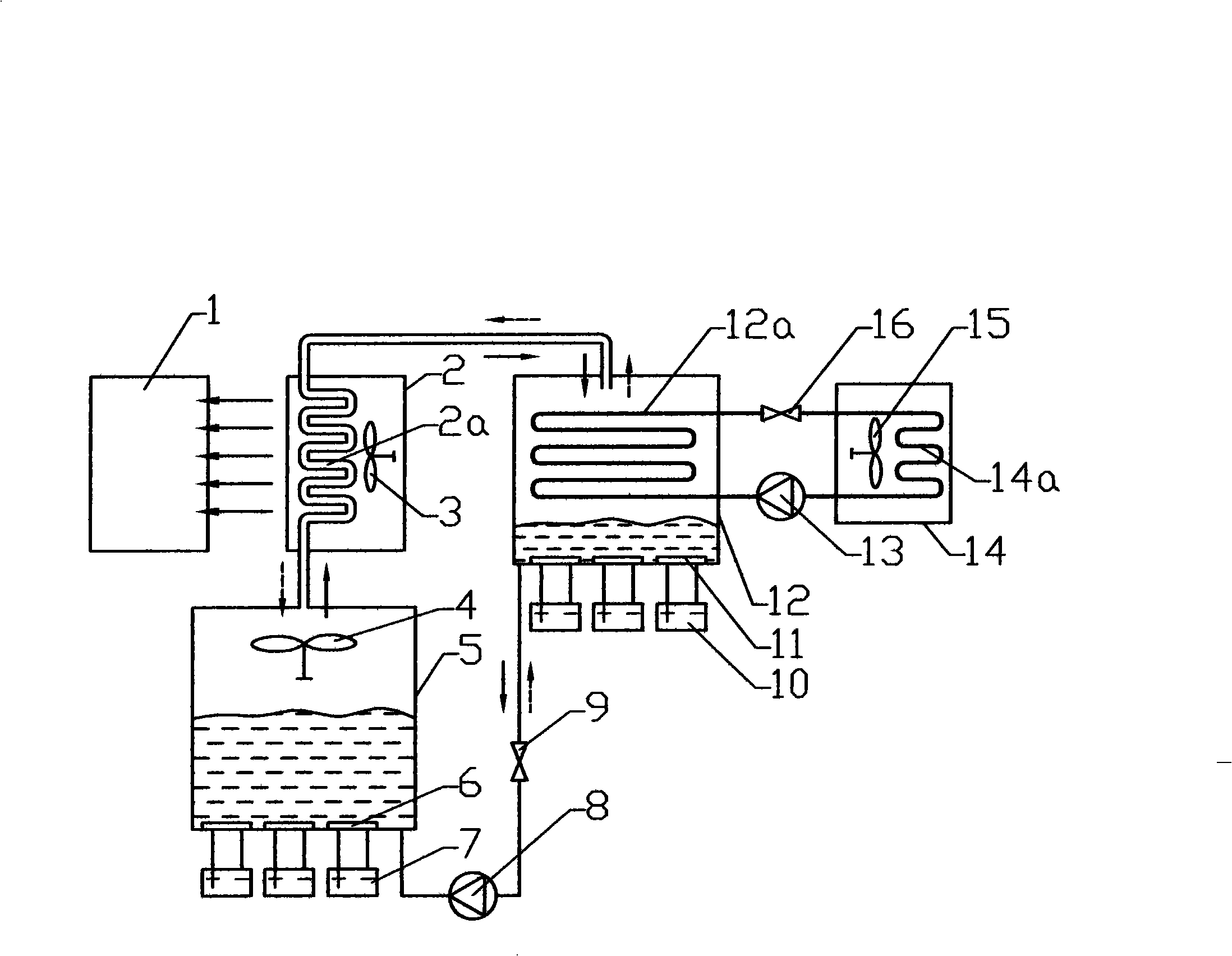

Embodiment 1

[0030] Embodiment 1 The refrigeration and heating dual-effect air-conditioning system using ultrasonic atomization technology in this embodiment, its working principle can be obtained from figure 1 As seen in the figure, it includes an indoor heat exchanger 2, an indoor heat exchange fan 3, an outdoor heat exchanger 14, an outdoor heat exchange fan 15, and also includes a first atomizer 5 and a second atomizer 12 with refrigerant inside, And at the mass transfer auxiliary fan 4 of the first atomizer 5; the first ultrasonic transducer 6 is placed in the refrigerant liquid at the bottom of the first atomizer 5, and its positive and negative electrodes are respectively connected to the first ultrasonic generator 7 The positive and negative electrodes are connected; the second ultrasonic transducer 11 is placed in the refrigerant liquid at the bottom of the second atomizer 12, and its positive and negative electrodes are respectively connected to the positive and negative electrode...

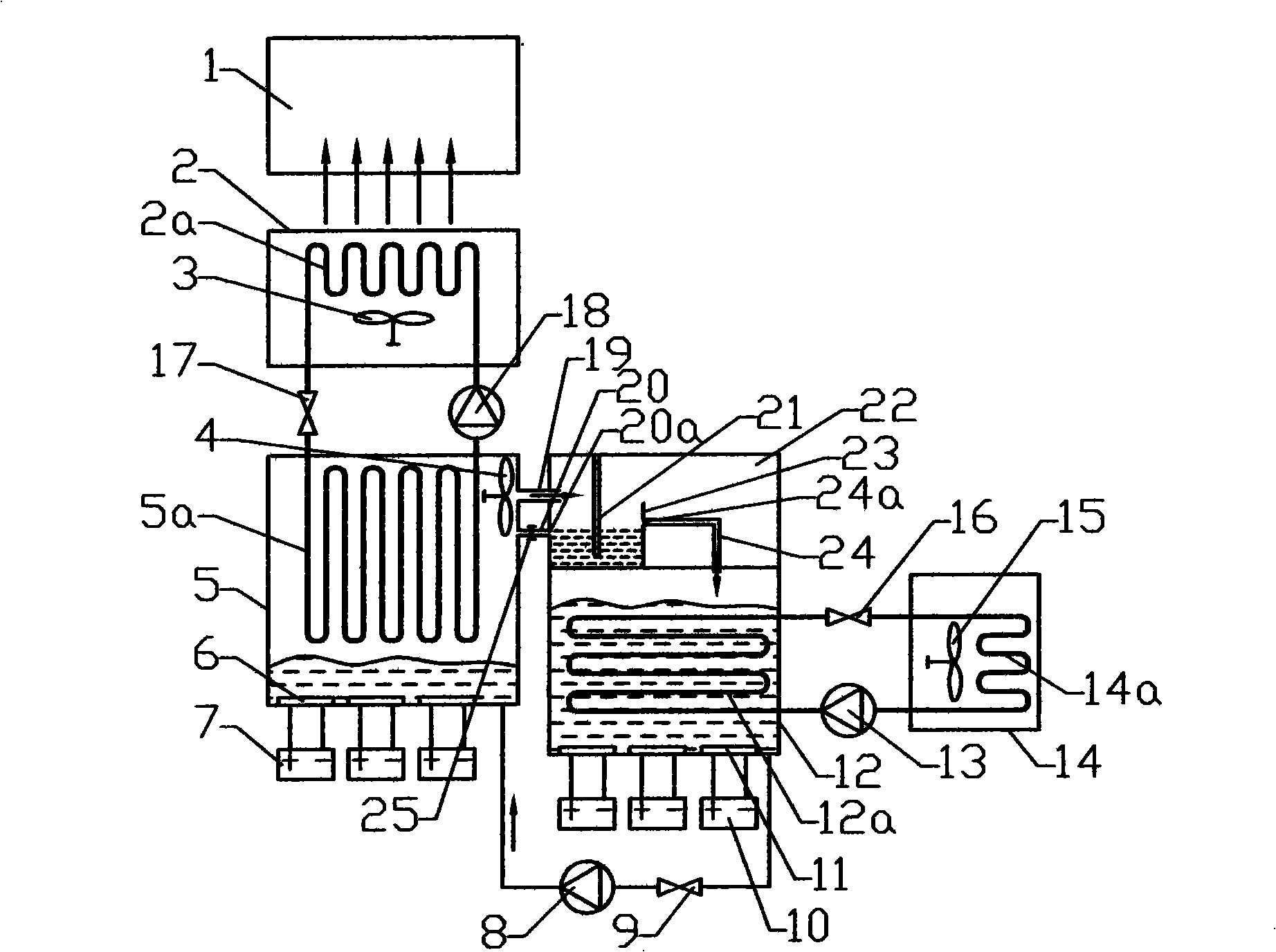

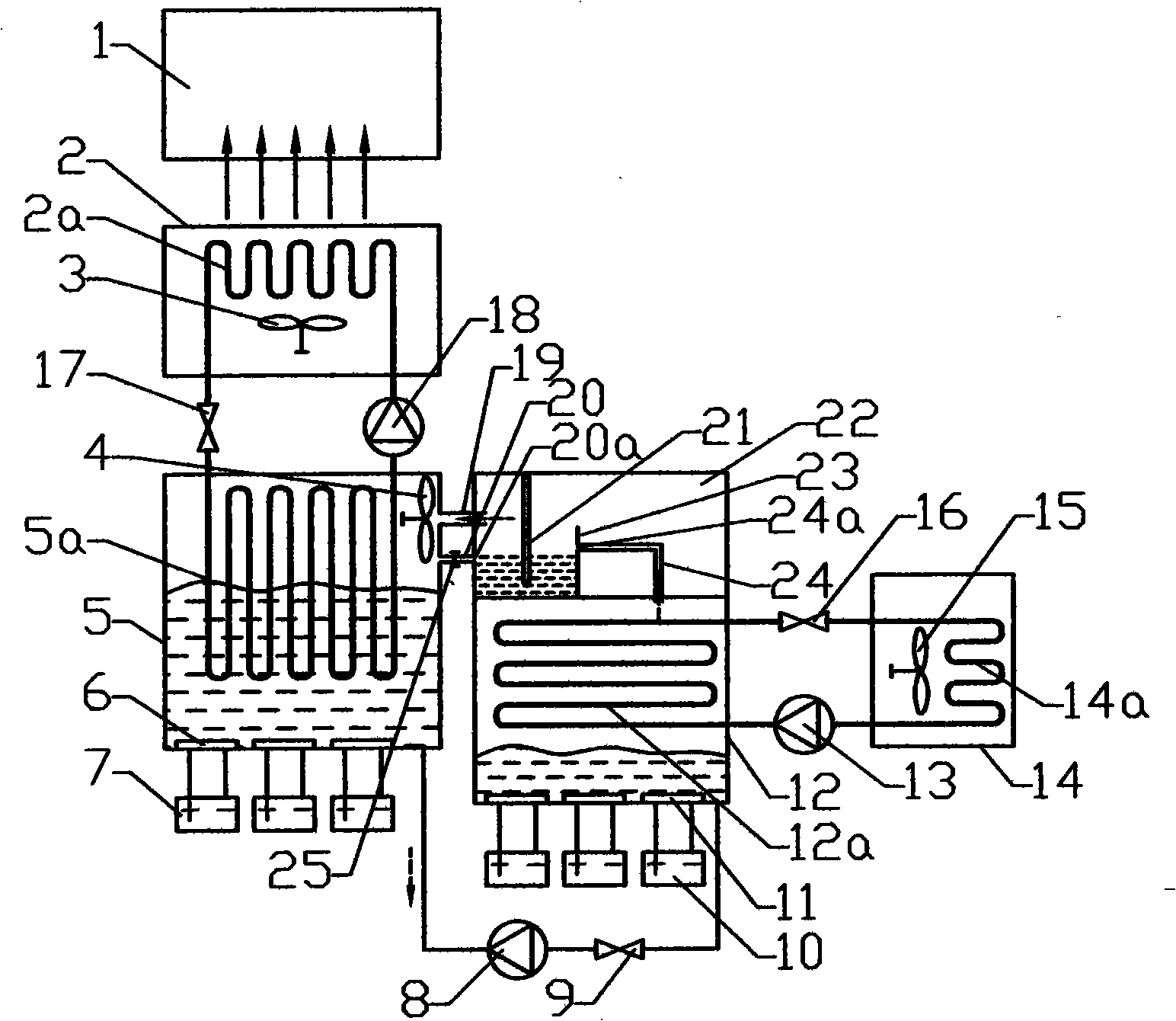

Embodiment 2

[0038] Example 2 The working principle of the cooling and heating dual-effect air-conditioning system using ultrasonic atomization technology in this example can be obtained from figure 2 , image 3 and Figure 4 As can be seen in the figure, it is different from Embodiment 1 in that a heat exchange coil 5a is arranged in the first atomizer 5, and the inlet and outlet ends of the heat exchange coil 5a communicate with the indoor heat through the throttle valve 17 and the circulation pump 18 respectively. The inlet and outlet ends of the heat exchange coil 2a in the exchanger 2 are connected; and there is an absorption chamber 22 with a built-in absorption tank 23 above the second atomizer 12, and a cooling overflow pipe 24 and a heating overflow pipe are installed on the upper part of the side wall of the absorption tank 22. The flow pipe 20 leads to the second atomizer 12 and the first atomizer 5 respectively, wherein the overflow port 20a of the heating overflow pipe 20 is...

Embodiment 3

[0049] Embodiment 3 The refrigeration and heating double-effect air-conditioning system using ultrasonic atomization technology in this embodiment, its working principle can be obtained from Figure 5 Seen in, it differs from embodiment 1 or 2 in that: a spray pump (27,28) with a nozzle (26,29) is all adorned on the first atomizer 5 and the second atomizer 12, The nozzle 29 in the second atomizer 12 is located below the heat exchange coil 12a, and the spray pumps (27, 28) realize spraying the refrigerant inside the first atomizer 5 and the second atomizer 12 , the first ultrasonic transducer 6 and the second ultrasonic transducer 11 are respectively located below the nozzle 26 in the first atomizer 5 and the nozzle 29 in the second atomizer 12, and above the liquid level of the refrigerant. Atomization of shower liquid.

[0050] During cooling operation, the spray pump 27 causes the refrigerant in the first atomizer 5 to spray, and the first ultrasonic transducer 6 in the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com