Method for surface treatment of Cr-steel

A surface-treated, chrome-steel technology, applied in blade support elements, engine elements, machines/engines, etc., that solves problems such as cost-intensive, unsatisfactory structure, not always reliable, and achieves high oxidation resistance and solid Particle corrosion resistance, less weight gain, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

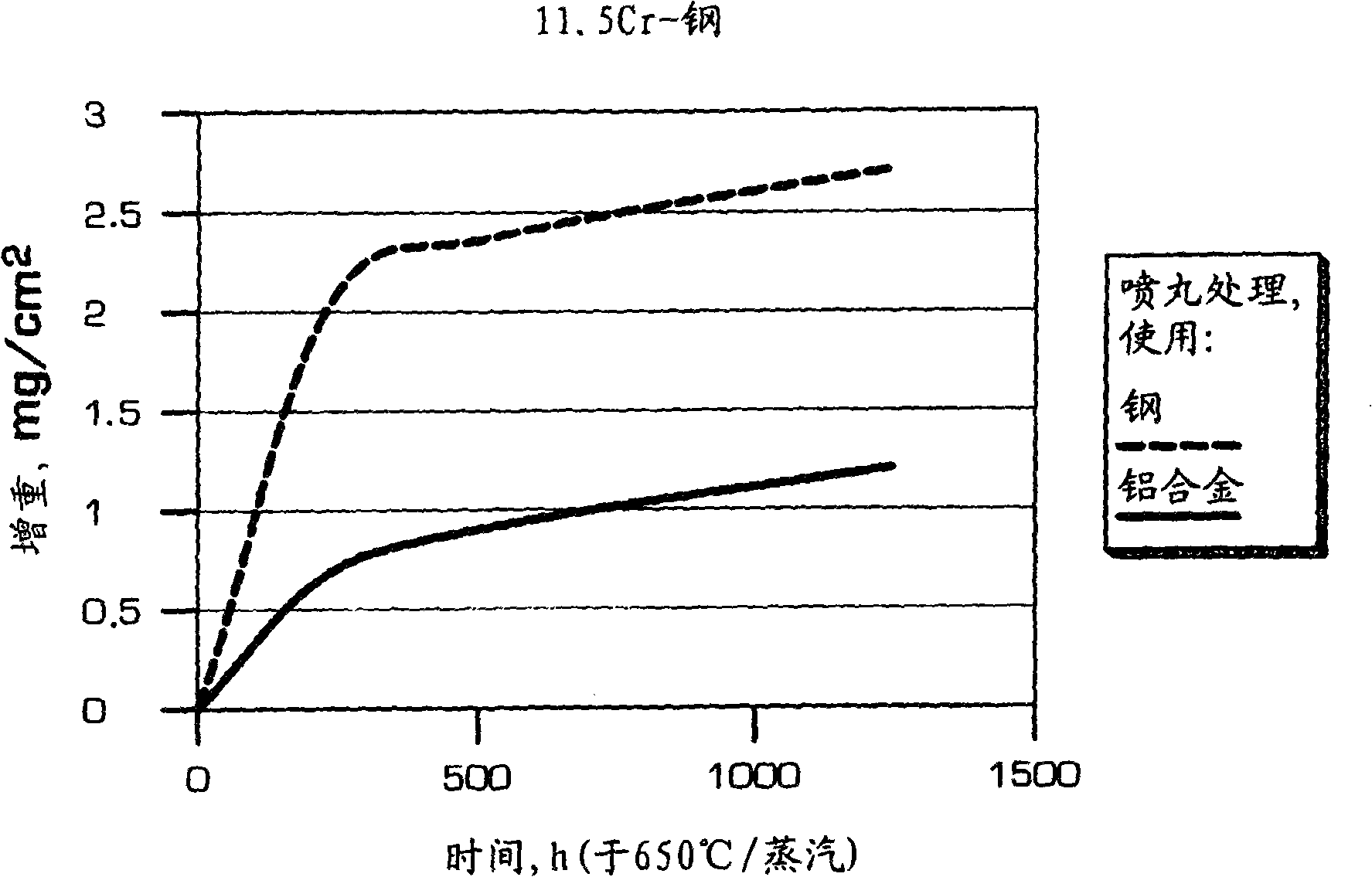

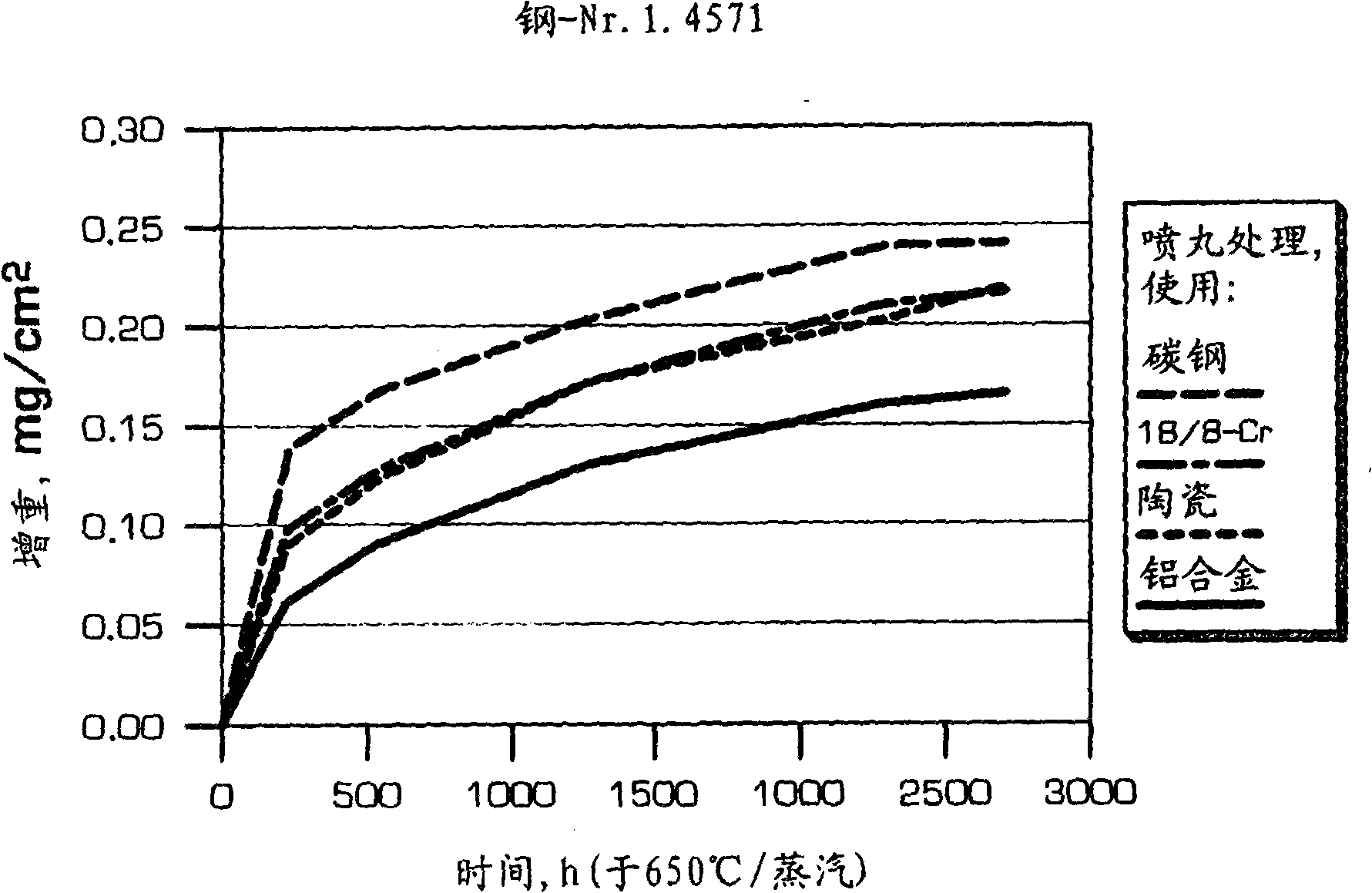

[0016] According to the following examples and Figures 1 to 2 The invention is further elucidated.

[0017] A ferritic chromium steel having the following chemical composition (weight % data) was treated according to the invention:

[0018] 0.2C

[0019] 0.5Mn

[0020] 0.28Si

[0021] 11.6Cr

[0022] 0.8Mo

[0023] 0.7Ni

[0024] 0.27V

[0025] The rest is iron and unavoidable impurities. In this embodiment, the above-mentioned steel material is shot-peened with aluminum alloy particles (particle size: 200-400 μm). Aluminum alloys have a hardness of 90 to 120 HV 0.2 and have the following chemical composition:

[0026] 5.5~7%Cu

[0027] <1%Fe

[0028] >1.6% Si

[0029] ≤1.5%Zn

[0030] ≤0.15Ti

[0031] ≤0.2Ni

[0032] ≤0.3Mn

[0033] ≤0.15Pb

[0034] ≤0.1Sn.

[0035] The steel surface is shot peened with the above particles for 5 minutes, where the pressure is about 6 bar and the angle of the nozzle to the surface is 80-85°.

[0036] Advantageously, subsequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com