Hot cathode fluorescent lamp filament current control circuit

A filament current and control circuit technology, applied to light sources, electric light sources, electrical components, etc., can solve the problems of shortening the life of lamp tubes, tungsten evaporation, and affecting the luminous efficiency of fluorescent lamps, achieving soft start and soft shutdown, Achieving Precisely Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

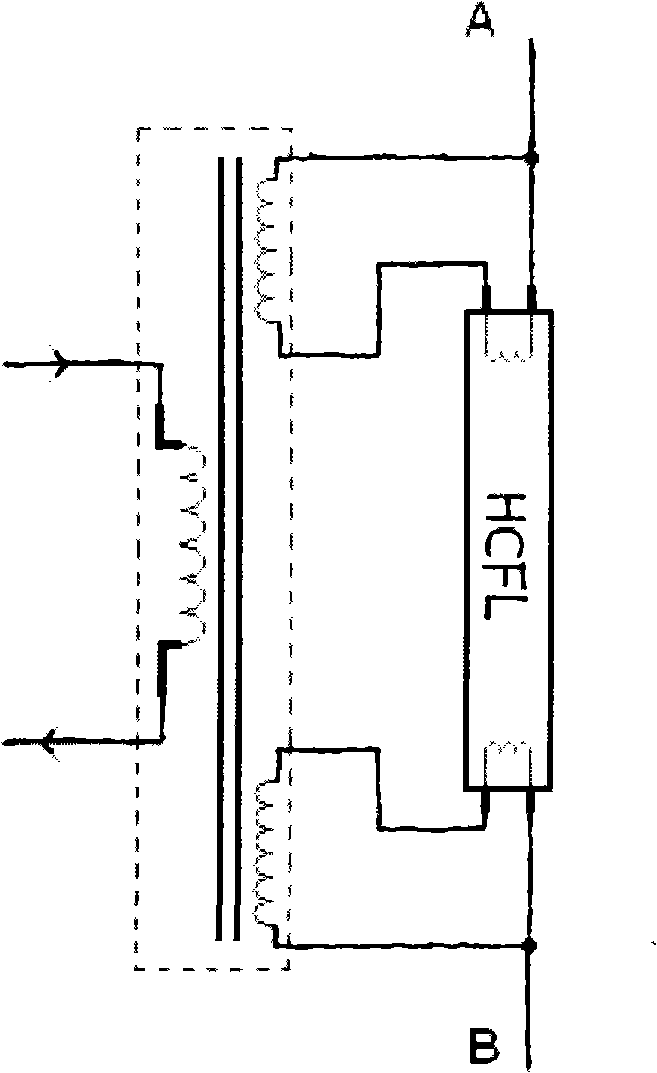

[0024] The hot cathode fluorescent lamp filament current control circuit of the present invention is as follows: Figure 7 and Figure 8 As shown, the circuit includes a filament heating transformer 1, the filament heating transformer 1 includes a primary coil and at least one secondary coil, and also includes a filament current control loop, the filament current control loop includes a power switch 2, a control logic 3, a multi-input comparator 4. Current control switch 5, oscillator OSC, reference voltage source VREF, reference current source IFER, primary coil current sampling resistor R0, filter capacitor C1, filter resistor R1 and other devices. The two ends of the secondary coil of the filament heating transformer 1 are respectively connected with the two ends of a hot cathode filament of the fluorescent lamp. It is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com