Epoxy resin micro-capsule and its preparation method

An epoxy resin and microcapsule technology, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems of unsuitable scale production, complicated polymerization process, and long polymerization time, and achieve easy large-scale preparation, simple process, and granular The effect of narrow diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Dissolve 15g of gum arabic in 500g of deionized water, and add 20g of epoxy resin E-51 for the core material, 5g of epoxy acrylate for wall material E-51, 15g of SVS, and 0.5g of PETA in sequence under stirring in a homogenizer And UV-907 0.2g of the mixture, emulsified for 10min, to obtain an oil-in-water emulsion.

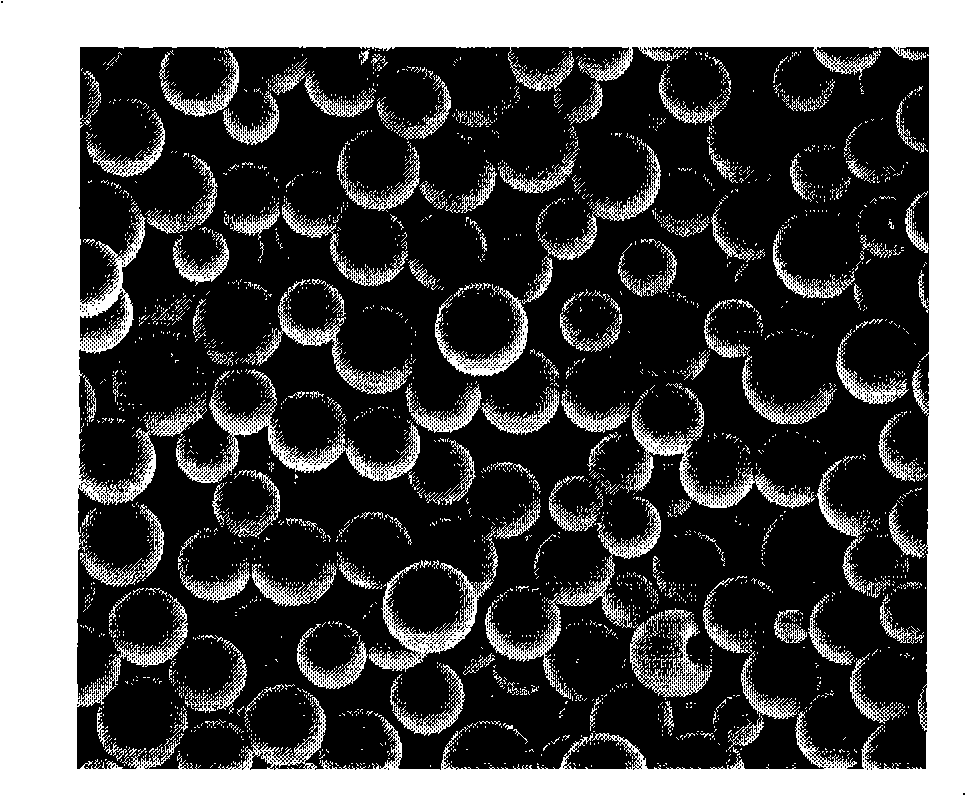

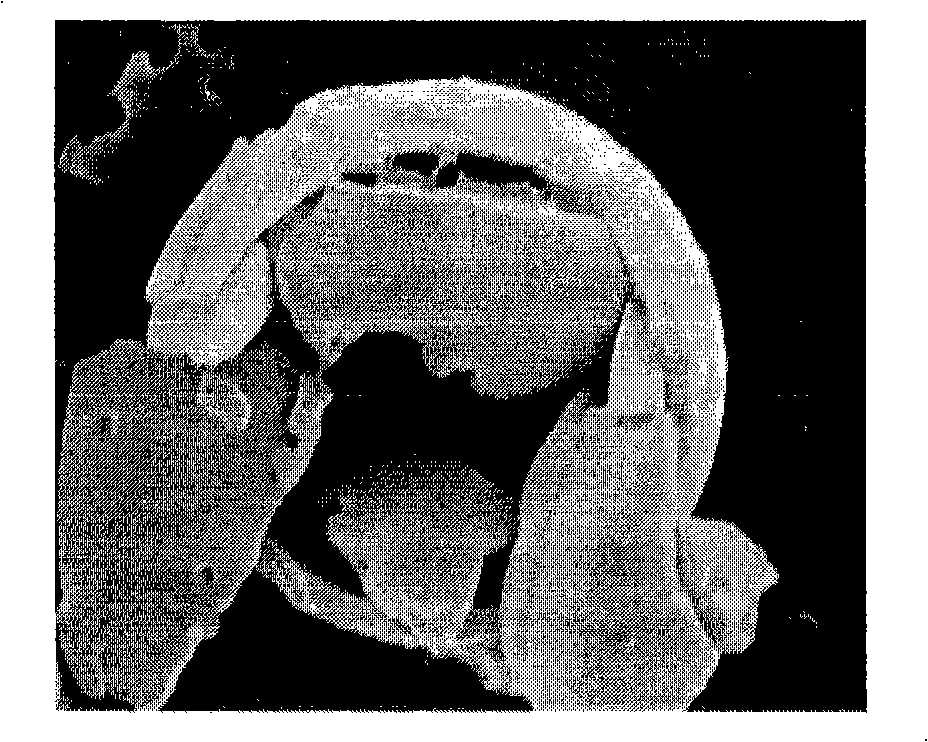

[0030] (2) Immediately irradiate the oil-in-water emulsion obtained in step (1) with ultraviolet light (power 1500w, lamp distance 10cm) for 10 minutes to make the surface of the oil-in-water solidify into a film, add a large amount of water to repeatedly settle and wash, and the microcapsule precipitate Vacuum freeze-drying to obtain a microcapsule product, the average diameter of the microcapsule is 25 μm, the wall thickness is 200 nm, and the weight ratio of capsule core / capsule wall is 2.0. The scanning electron microscope image of the microcapsules is shown in figure 1 , the scanning electron microscope image of the ruptured microcapsules is show...

Embodiment 2

[0032] (1) Dissolve 15g of gelatin in 500g of deionized water, add core material epoxy resin J-8020g and wall material J-80 epoxy acrylate 5g, HPMAS 15g, TMPTMA 0.5g and UV - 11730.2g of the mixture, emulsified for 10min to obtain an oil-in-water emulsion.

[0033] (2) Immediately irradiate the oil-in-water emulsion obtained in step (1) with ultraviolet light (power 1500w, lamp distance 10cm) for 10 minutes to make the surface of the oil-in-water solidify into a film, add a large amount of water to repeatedly settle and wash, and the microcapsule precipitate Vacuum freeze-drying to obtain a microcapsule product, the average diameter of the microcapsule is 20 μm, the wall thickness is 250 nm, and the weight ratio of capsule core / capsule wall is 1.8.

Embodiment 3

[0035] (1) Dissolve 15g of ethylene-maleic anhydride copolymer sodium salt in 500g of deionized water, and add 20g of core material epoxy resin 711 and 5g of wall material E-711 epoxy acrylate, HAPS in sequence under stirring in a homogenizer The mixture of 15g, TRGTMA 0.5g and UV-1840.2g was emulsified for 10min to obtain an oil-in-water emulsion.

[0036] (2) Immediately irradiate the oil-in-water emulsion obtained in step (1) with ultraviolet light (power 1500w, lamp distance 10cm) for 10 minutes to make the surface of the oil-in-water solidify into a film, add a large amount of water to repeatedly settle and wash, and the microcapsule precipitate Vacuum freeze-drying to obtain a microcapsule product, the average diameter of the microcapsule is 15 μm, the wall thickness is 300 nm, and the weight ratio of capsule core / capsule wall is 1.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com