Method for preparing high-alkali value (TBN300) synthesized calcium alkyl benzene sulfonate

A technology of calcium alkyl benzene sulfonate and alkyl benzene sulfonic acid is applied in the preparation of sulfonic acid, lubricating composition, additives, etc., and can solve the problems of high production cost and product price, poor product anti-foaming, poor product quality, etc. , to achieve the effect of low production and processing cost, good foam resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

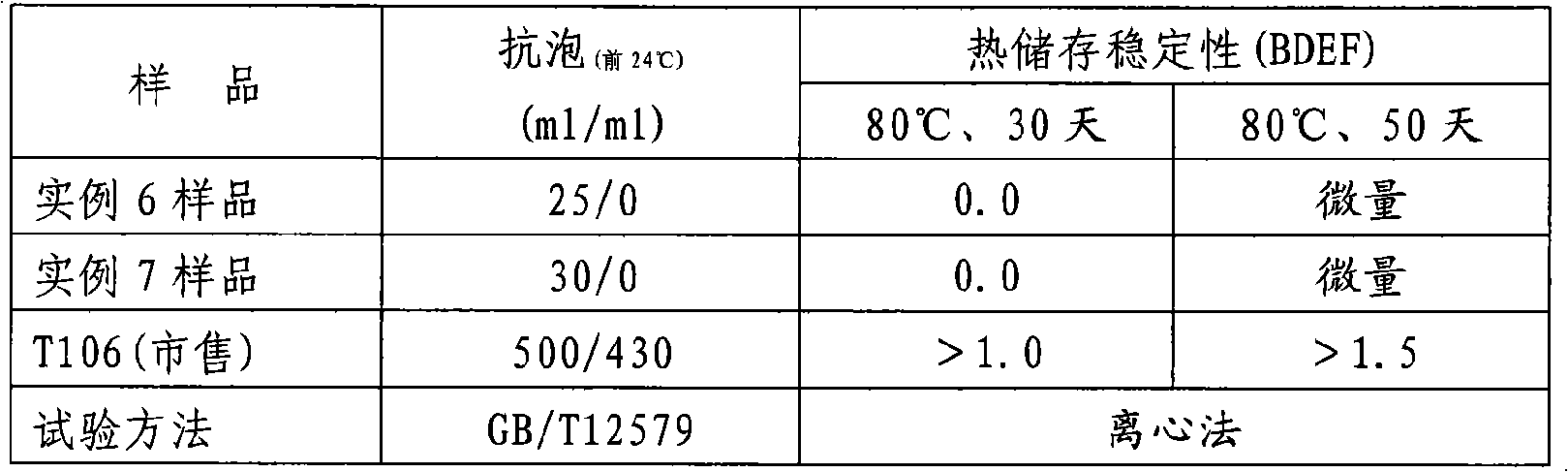

Examples

example 1

[0023]The process is: mix the mixed acid of long-chain linear alkylbenzene sulfonic acid and high-boiler heavy alkylbenzene sulfonic acid with calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline earth metal halide, polyisobutenyl The mixture of succinic anhydride, alkaline earth metal alkylphenol and diluent oil is neutralized at 40°C in the presence of alkanes, aromatic hydrocarbons or low-carbon alcohols with a boiling point higher than 80°C as a solvent, and then carbon dioxide is introduced The carbonation reaction was carried out at a temperature of 40°C. The carbonation reaction is completed once, that is, calcium oxide and / or calcium hydroxide is added at one time, and carbon dioxide is introduced at a rate of 0.1L / min. The molar ratio of the amount of carbon dioxide introduced to the total amount of calcium oxide and / or calcium hydroxide 0.72:1 until the end of the carbonation reaction. Then heat up to 140°C to remove solvents and light components (th...

example 2

[0027] The process is: mix the mixed acid of long-chain linear alkylbenzene sulfonic acid and high-boiler heavy alkylbenzene sulfonic acid with calcium oxide and / or calcium hydroxide, low-carbon alcohol, nitrate, polyisobutenyl butane The mixture of acid anhydride, alkaline earth metal alkyl phenate and diluent oil is neutralized at 80°C in the presence of alkanes, aromatic hydrocarbons or low-carbon alcohols with a boiling point higher than 80°C as a solvent, and carbon dioxide is introduced into the The carbonation reaction was carried out at a temperature of 60°C. The carbonation reaction is carried out in three times, that is, calcium oxide and / or calcium hydroxide is added in three times, and carbon dioxide is introduced in three times at a rate of 2.5L / min. The amount of carbon dioxide introduced is the same as that of calcium oxide and / or calcium hydroxide. The molar ratio of the total amount is 0.90:1 until the carbonation reaction ends. Then heat up to 180°C to remov...

example 3

[0031] The process is: mix the mixed acid of long-chain linear alkylbenzene sulfonic acid and high-boiler heavy alkylbenzene sulfonic acid with calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline earth metal halide, polyisobutenyl The mixture of succinic anhydride, alkaline earth metal alkylphenol and diluent oil is neutralized at 60°C in the presence of alkanes, aromatic hydrocarbons or low-carbon alcohols with a boiling point higher than 80°C as a solvent, and then carbon dioxide is introduced The carbonation reaction was carried out at a temperature of 50°C. The carbonation reaction is carried out twice, that is, calcium oxide and / or calcium hydroxide is added in two times, and carbon dioxide is introduced in two times at a rate of 1L / min. The amount of carbon dioxide introduced is equal to the total amount of calcium oxide and / or calcium hydroxide. The molar ratio of the amounts was 0.80:1 until the carbonation reaction was completed. Then raise the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total base number | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Total base number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com