Method for decomposing phosphogypsum to produce sulphuric acid and cement with suspended state

A phosphogypsum and lime technology, applied in the direction of sulfur trioxide/sulfuric acid, sustainable manufacturing/processing, calcium/strontium/barium oxide/hydroxide, etc., can solve the problem of high decomposition temperature of phosphogypsum, long decomposition time, production Small scale and other issues, to achieve the effect of accelerating heat transfer rate and decomposition rate, accelerating decomposition efficiency, and saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

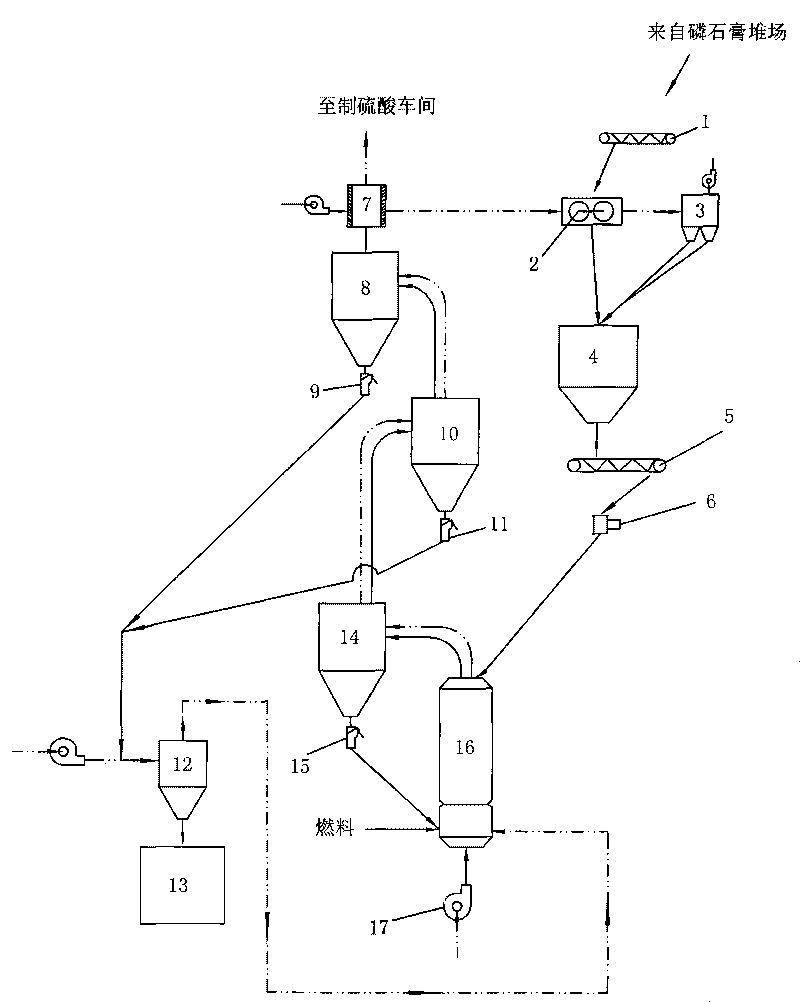

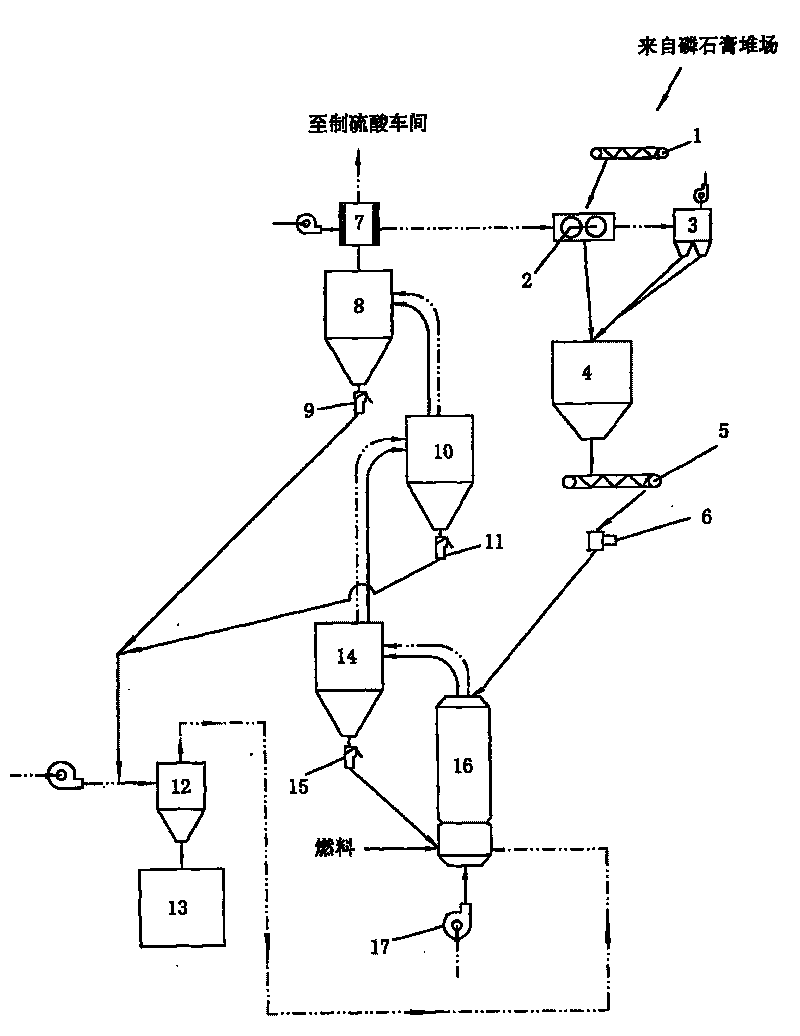

[0016] Referring to accompanying drawing, the method for preparing sulfuric acid co-production lime with suspended state decomposing phosphogypsum comprises the following steps:

[0017] a) Crushing and drying: the phosphogypsum raw material is sent to the hammer crusher 2 for crushing through the belt conveyor 1, and the hot gas (150-250°C) in the gas cooler 7 is passed through the pipeline into the hammer crusher 2 to dry the material , so that the waste heat can be fully utilized; the crushed raw materials are put into the dry powder bin 4, and the exhaust gas dried in the hammer crusher 2 is discharged into the atmosphere after being collected by the dust collector 3 up to the standard; the dry powder bin is fed through the weighing scale 5 and the rotary feeding Device 6 enters the upper pipeline of phosphogypsum decomposition furnace 16;

[0018] The characteristics of crushing and drying: the raw materials are fully crushed and dried, and the waste heat is fully utilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com