Method of manufacturing toner for static charge phase development and toner

A manufacturing method and toner technology, which are applied in the directions of developers, electrographics, instruments, etc., can solve the problem of unclear wax dispersion state, and achieve the effects of excellent anti-rubbing and low-temperature fixability, excellent developability, and high resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

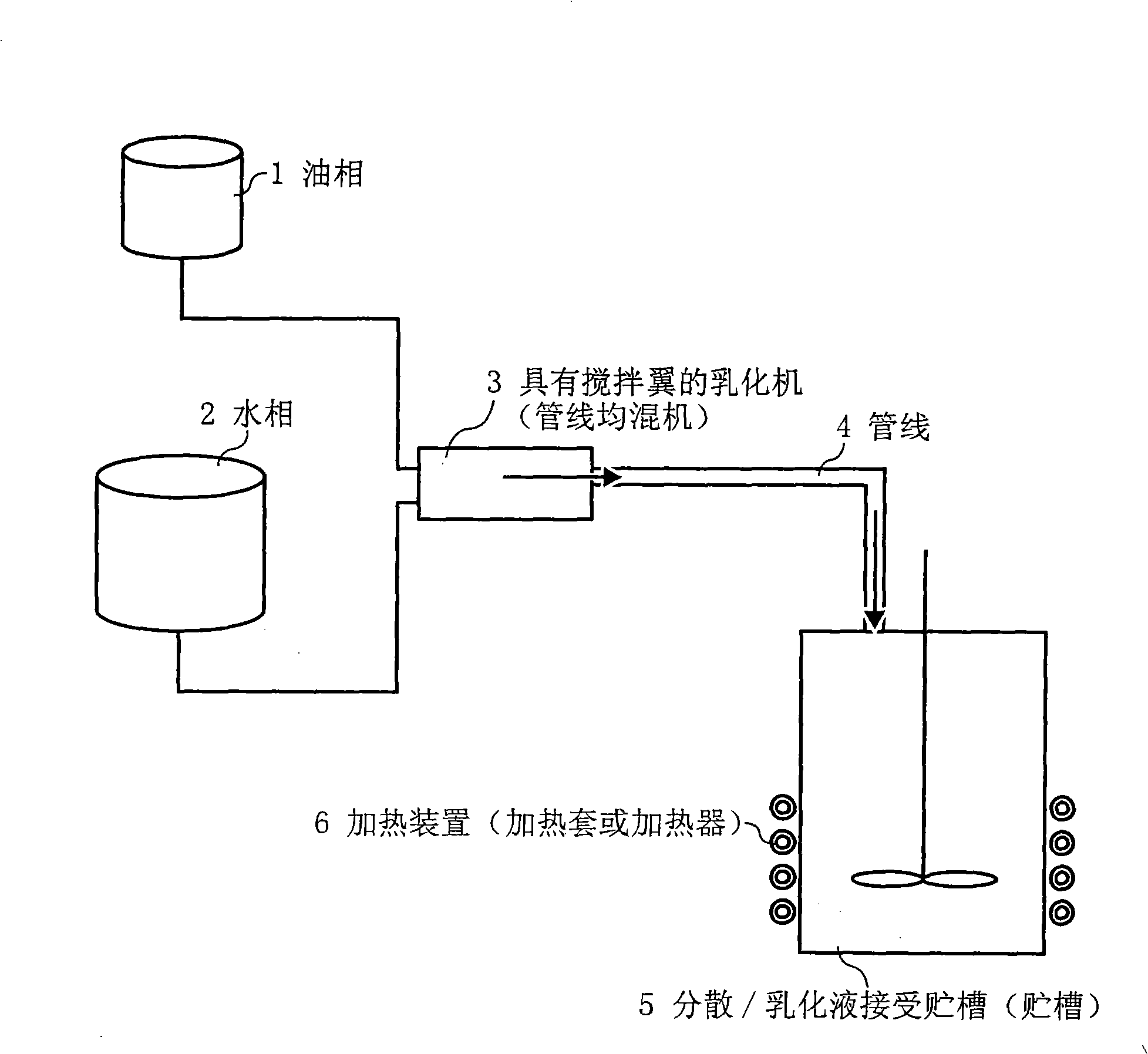

Method used

Image

Examples

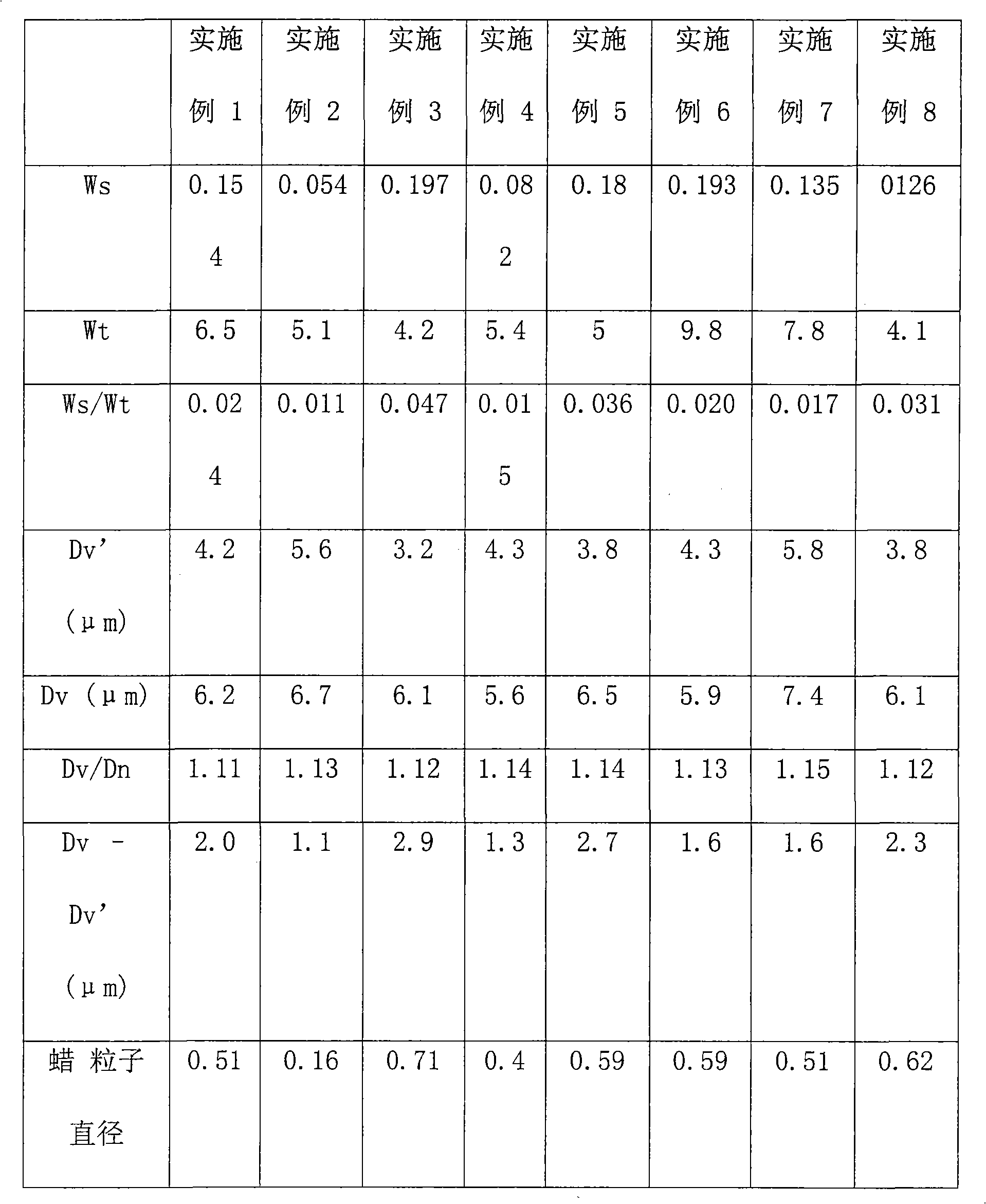

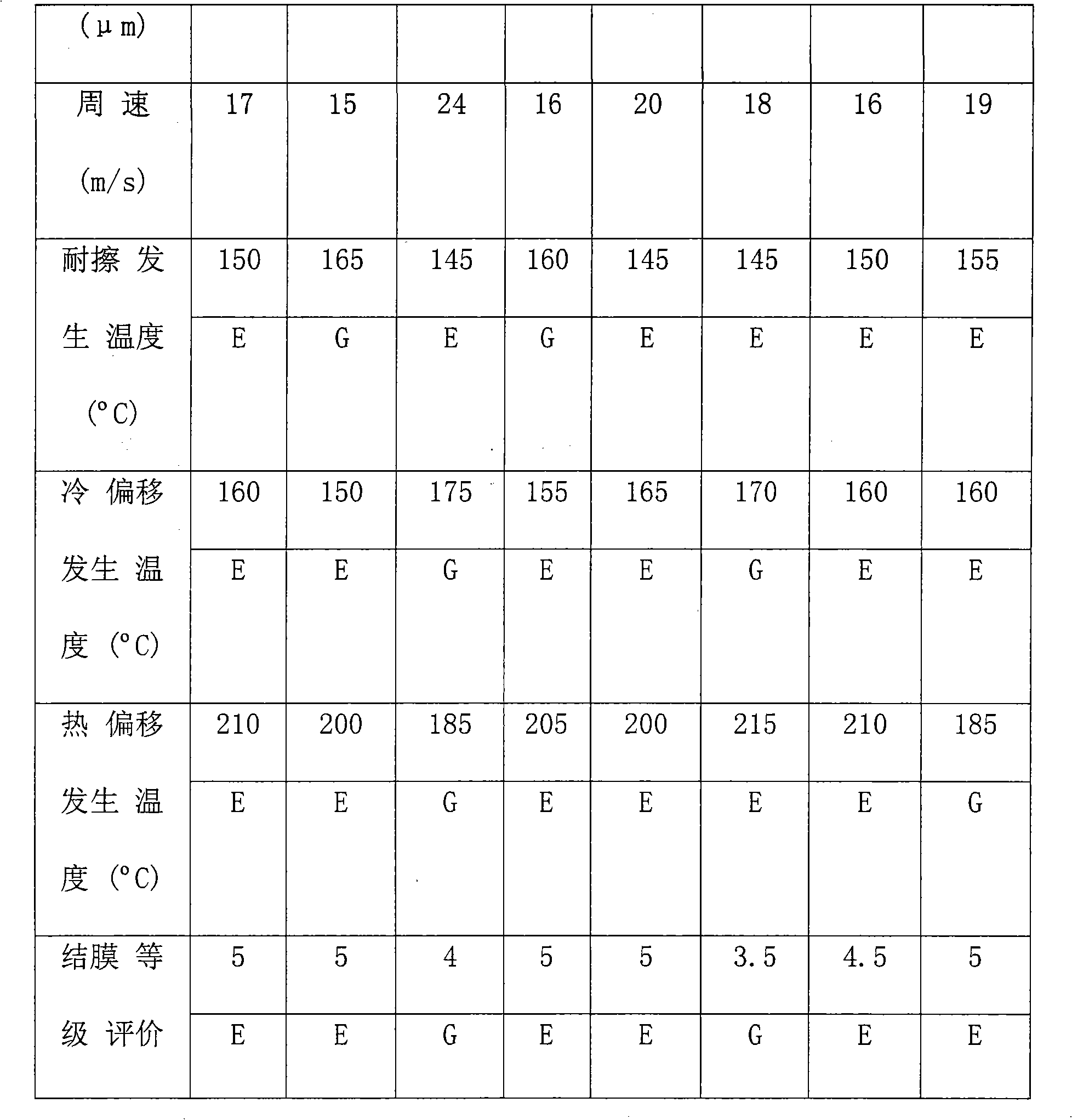

Embodiment 1

[0141] (production of polyester)

[0142] Add 690 parts of ethylene oxide 2 moles adduct of bisphenol A and 335 parts of terephthalic acid to the reaction tank with cooling tube, stirrer and nitrogen introduction tube, and carry out at 210°C under normal pressure nitrogen flow. 10 hours condensation reaction. Next, the reaction was continued for 5 hours while dehydrating under a reduced pressure of 10 to 15 mmHg, and then cooled to obtain polyester (1). The resin of the obtained polyester (1) had a weight average molecular weight of 6000, an acid value of 10 KOHmg / g, and a glass transition point of 48°C.

[0143] (manufacture of prepolymer)

[0144] Add 795 parts of ethylene oxide 2 molar adducts of bisphenol A, 200 parts of isophthalic acid, 65 parts of terephthalic acid, and dibutyltin Oxide 2 parts. The condensation reaction was carried out at 210° C. for 8 hours under a nitrogen flow at normal pressure. Next, under a reduced pressure of 10-15mmHg, react for 5 hours wh...

Embodiment 2

[0157] (Manufacture of wax dispersion)

[0158] Except that the bead diameter in embodiment 1 is changed to 0.3mm, the number of revolutions of the bead mill is changed to 600rpm, and the residence time in the bead mill is changed to 10min, the same operation as in embodiment 1 is carried out to obtain a wax with a wax particle diameter of 0.16 μm. Dispersion (2).

[0159] (manufacture of organic solvent composition)

[0160] An organic solvent composition (3) was obtained in the same manner as in Example 1, except that the wax dispersion (1) was changed to the above-mentioned wax dispersion (2).

[0161] (production of toner)

[0162] In addition to changing the above-mentioned organic solvent composition (1) into the above-mentioned organic solvent composition (3), the supply rate is 3240g / min, in addition, the supply rate of the above-mentioned organic solvent composition (2) is set to 400g / min, the above-mentioned The same operation as in Example 1 was carried out excep...

Embodiment 3

[0164] (Manufacture of wax dispersion)

[0165] Except that the rotation speed of the bead mill in Example 1 was changed to 400 rpm, and the residence time in the bead mill was changed to 5 minutes, the same operation as in Example 1 was carried out to obtain a wax dispersion (3) with a wax particle size of 0.66 μm.

[0166] (manufacture of organic solvent composition)

[0167] Except having changed the said wax dispersion liquid (1) into the said wax dispersion liquid (3), it carried out similarly to Example 1, and obtained the organic solvent composition (4).

[0168] (production of toner)

[0169] Except changing the above-mentioned organic solvent composition (1) into the above-mentioned organic solvent composition (4), the supply rate is set to 5265g / min, in addition, the supply rate of the above-mentioned organic solvent composition (2) is set to 650g / min, A yellow toner (3) was obtained in the same manner as in Example 1, except that the supply rate of the water-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com