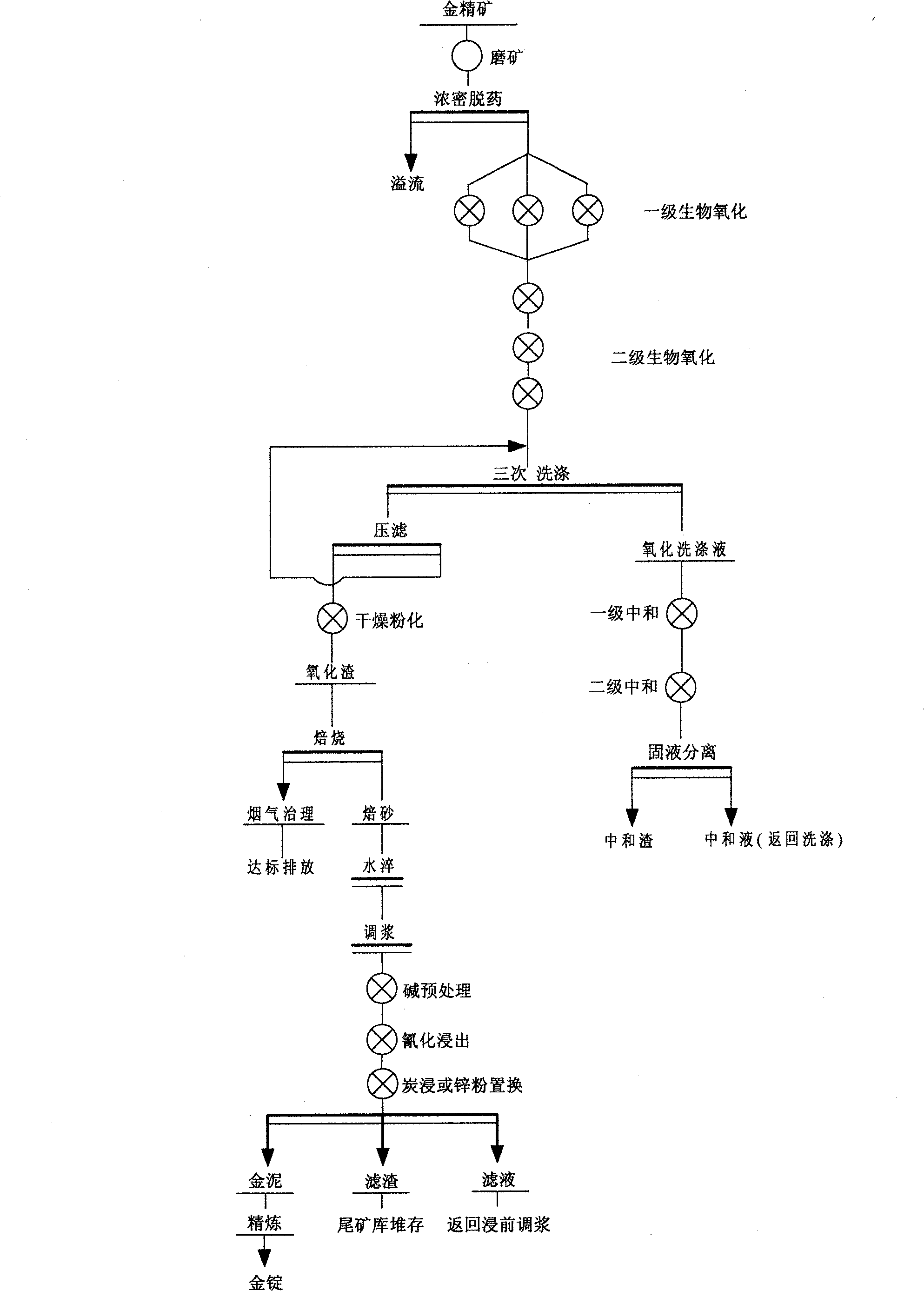

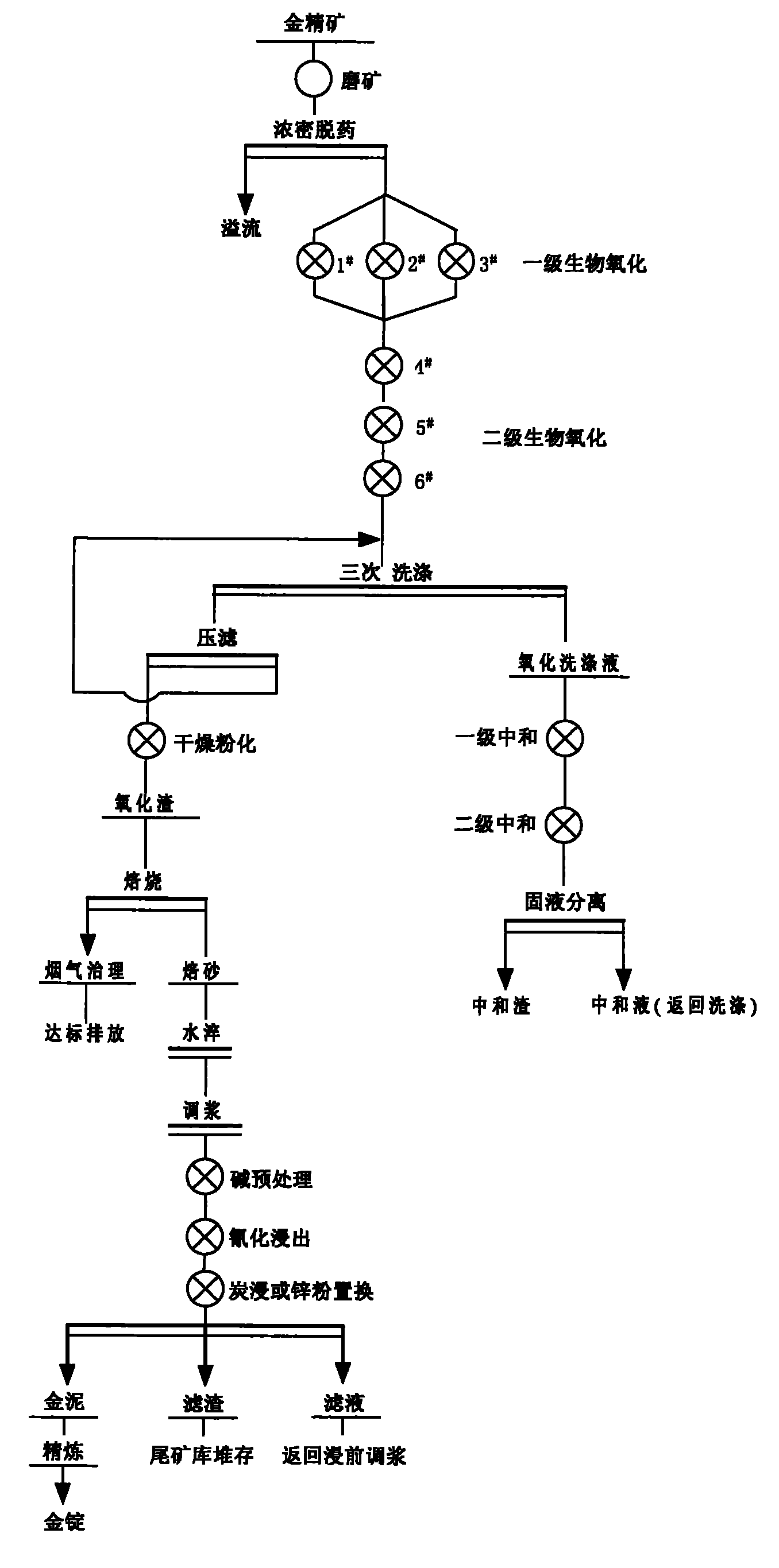

Golden shifting process of biological oxidation-torrefaction-cyanidation

A bio-oxidation and roasting technology, applied in the direction of improving process efficiency, can solve problems such as inability to effectively recover gold, and achieve the effect of improving leaching rate and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

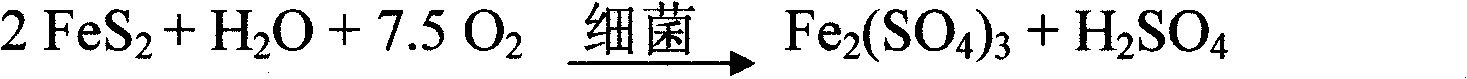

Method used

Image

Examples

Embodiment 1

[0094] (1) Grinding and grading operations:

[0095]Grind the above-mentioned refractory gold concentrate until the particle size is -0.045mm and the content is 95%, and then carry out dense drug removal and adjust the pulp concentration to 16%;

[0096] (2) Biological oxidation operation:

[0097] Feed the ore pulp with a pulp concentration of 16% in step (1) into the biological oxidation system, and ensure that the pH is 1-2; the temperature is 40°C; the dissolved oxygen content is 4mg / l; the medium consumption is 4kg / t; the oxidation time is 7 days Under the process conditions, the biological oxidation operation is carried out. After the oxidized oxidation washing liquid undergoes primary neutralization and secondary neutralization to remove arsenic, solid-liquid separation is carried out, the neutralization slag is discharged, the neutralization liquid is returned to the washing system, and the oxidation slag is re- After pressure filtration, drying and pulverization, ent...

Embodiment 2

[0108] (1) Grinding and grading operations:

[0109] Grind the above-mentioned refractory gold concentrate until the particle size is -0.045mm and the content is 95%, and then carry out dense drug removal and adjust the pulp concentration to 18%;

[0110] (2) Biological oxidation operation:

[0111] Feed the pulp with a pulp concentration of 18% in step (1) into the biological oxidation system, and ensure that the pH is 1-2; the temperature is 38°C; the dissolved oxygen content is 4mg / l; the medium consumption is 3kg / t; the oxidation time is 7 days Under the process conditions, the biological oxidation operation is carried out. After the oxidized oxidation washing liquid undergoes primary neutralization and secondary neutralization to remove arsenic, solid-liquid separation is carried out, the neutralization slag is discharged, the neutralization liquid is returned to the washing system, and the oxidation slag is re- After pressure filtration, drying and pulverization, enter ...

Embodiment 3

[0122] (1) Grinding and grading operations:

[0123] Grind the above-mentioned refractory gold concentrate until the particle size is -0.045mm and the content is 95%, and then carry out dense drug removal and adjust the pulp concentration to 16%;

[0124] (2) Biological oxidation operation:

[0125] Feed the pulp with a pulp concentration of 16% in step (1) into the biological oxidation system, and ensure pH = 1-2; the temperature is 42°C; the dissolved oxygen content is 5mg / l; the medium consumption is 4kg / t; the oxidation time is 8 days Under the process conditions, the biological oxidation operation is carried out. After the oxidized oxidation washing liquid undergoes primary neutralization and secondary neutralization to remove arsenic, solid-liquid separation is carried out, the neutralization slag is discharged, the neutralization liquid is returned to the washing system, and the oxidation slag is re- After pressure filtration, drying and pulverization, enter the next s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com