Galactose-artemisinin and method for preparing same

A technology of galactose and artemisinin, which is applied in pharmaceutical formulations, sugar derivatives, medical preparations containing active ingredients, etc., can solve the problems of product or environmental pollution, increase of reaction steps, complicated separation and purification, etc. The effect of poor treatment selectivity, improved activity, and improved efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

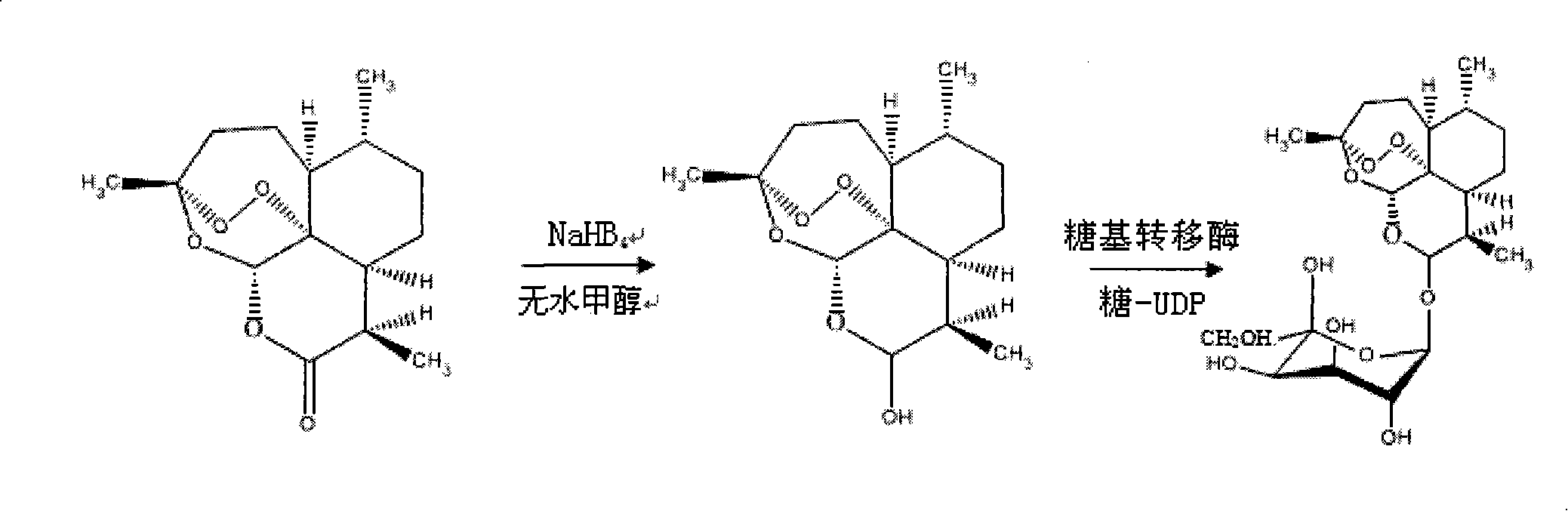

[0068] Example 1. Synthesis of receptors—reduction of artemisinin

[0069] Add 2.81g (0.01mol) artemisinin, 0.454g (0.012mol) NaHB 4 And 10mL of anhydrous methanol stirred at room temperature for 24h. The filtrate was distilled under reduced pressure to recover methanol. The residue was dissolved in 250 mL of water, then extracted three times with 50 mL of ethyl acetate, the organic layer was washed with a small amount of water, and the water washings and the water layer were combined. It was extracted with ethyl acetate, and the organic layers were combined. Evaporation of solvent, drying to obtain product - dihydroartemisinin;

Embodiment 2

[0070] Example 2. Synthesis of Donor——Preparation of UDP-Galactose

[0071] Dissolve 2.0 g of galactose in a 500 mL double-distilled water flask, and stir at a constant speed on a magnetic stirrer for 2 h. On a high-speed centrifuge at 12000rpm, centrifuge for 20min, and take the supernatant. Add 450mL of 0.4% galactose solution obtained in the previous step to 450mL of absolute ethanol, and stir gently; take out the milky white flocculent precipitate and put it in a flask, squeeze out excess water, add 450mL of deionized water, and stir until completely dissolved.

[0072] Take 20 mL of the reconstituted galactose solution, add different volumes of UDP respectively, and treat with 20 MHz, 36% ultrasonic wave for 30 min. Remove the free UDP in the solution, take 10 1.5mL Ep tubes, and add 1mL of the solution after ultrasonic treatment to each tube; turn on the vacuum centrifuge, set the temperature at 30°C, 1400rpm, and a vacuum of <20hPa, and place them in turn for 120min to...

Embodiment 3

[0073] Example 3. Enzyme-catalyzed synthesis process - preparation of galactose-artemisinin

[0074] see figure 1 . Dissolve 1.4107g (equivalent to 5mmol) of dihydroartemisinin in 50mmol / L sodium azide, add 10mmol of UDP-galactose, and 5μmol of galactose glycosyltransferase, and finally add pH7.4 phosphate buffer solution diluted to 10 mL. The entire solution was incubated at a constant temperature of 37° C. for 3 days at a rotational speed of 200 r / min. Then, fully dialyze with a dialysis bag in 50 mmol / L sodium azide, pH 7.4 phosphate buffer to remove unbound galactose molecules to obtain galactose-artemisinin (or glycosylated artemisinin).

[0075] The chemical name of the galactose-artemisinin is (3R, 5aS, 6R, 8aS, 9R, 12S, 12aR)-octahydro-3,6,9-trimethyl-3,12-oxo-12H- Pyrano[4,3-j]-1,2-benzodisepin-10-O-galactosyl, molecular formula C 21 h 34 o 10 , the molecular weight is 446.51, and the structural formula is:

[0076]

[0077] All samples were frozen in a -70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com